Page 28: of Maritime Reporter Magazine (December 2011)

Great Ships of 2011

Read this page in Pdf, Flash or Html5 edition of December 2011 Maritime Reporter Magazine

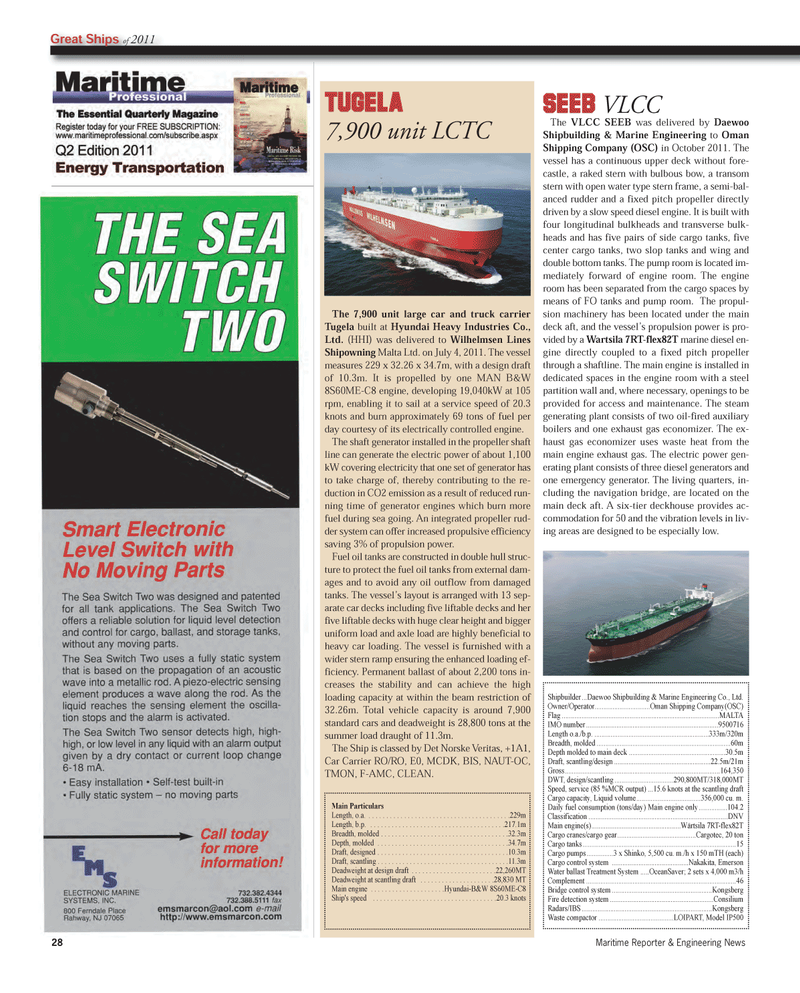

28Maritime Reporter & Engineering News Tugela 7,900 unit LCTC The 7,900 unit large car and truck carrier Tugela built at Hyundai Heavy Industries Co., Ltd. (HHI) was delivered to Wilhelmsen Lines Shipowning Malta Ltd. on July 4, 2011. The vessel measures 229 x 32.26 x 34.7m, with a design draftof 10.3m. It is propelled by one MAN B&W8S60ME-C8 engine, developing 19,040kW at 105 rpm, enabling it to sail at a service speed of 20.3knots and burn approximately 69 tons of fuel per day courtesy of its electrically controlled engine. The shaft generator installed in the propeller shaftline can generate the electric power of about 1,100 kW covering electricity that one set of generator has to take charge of, thereby contributing to the re- duction in CO2 emission as a result of reduced run-ning time of generator engines which burn more fuel during sea going. An integrated propeller rud- der system can offer increased propulsive efficiency saving 3% of propulsion power. Fuel oil tanks are constructed in double hull struc-ture to protect the fuel oil tanks from external dam- ages and to avoid any oil outflow from damaged tanks. The vessel?s layout is arranged with 13 sep- arate car decks including five liftable decks and her five liftable decks with huge clear height and bigger uniform load and axle load are highly beneficial to heavy car loading. The vessel is furnished with a wider stern ramp ensuring the enhanced loading ef-ficiency. Permanent ballast of about 2,200 tons in- creases the stability and can achieve the high loading capacity at within the beam restriction of32.26m. Total vehicle capacity is around 7,900 standard cars and deadweight is 28,800 tons at thesummer load draught of 11.3m.The Ship is classed by Det Norske Veritas, +1A1, Car Carrier RO/RO, E0, MCDK, BIS, NAUT-OC, TMON, F-AMC, CLEAN. SEEBVLCC The VLCC SEEBwas delivered by Daewoo Shipbuilding & Marine Engineering to OmanShipping Company (OSC)in October 2011. The vessel has a continuous upper deck without fore- castle, a raked stern with bulbous bow, a transom stern with open water type stern frame, a semi-bal- anced rudder and a fixed pitch propeller directly driven by a slow speed diesel engine. It is built with four longitudinal bulkheads and transverse bulk- heads and has five pairs of side cargo tanks, five center cargo tanks, two slop tanks and wing and double bottom tanks. The pump room is located im- mediately forward of engine room. The engine room has been separated from the cargo spaces by means of FO tanks and pump room. The propul- sion machinery has been located under the maindeck aft, and the vessel?s propulsion power is pro- vided by a Wartsila 7RT-flex82T marine diesel en-gine directly coupled to a fixed pitch propeller through a shaftline. The main engine is installed in dedicated spaces in the engine room with a steelpartition wall and, where necessary, openings to be provided for access and maintenance. The steam generating plant consists of two oil-fired auxiliary boilers and one exhaust gas economizer. The ex- haust gas economizer uses waste heat from the main engine exhaust gas. The electric power gen- erating plant consists of three diesel generators andone emergency generator. The living quarters, in- cluding the navigation bridge, are located on the main deck aft. A six-tier deckhouse provides ac- commodation for 50 and the vibration levels in liv- ing areas are designed to be especially low. Great Shipsof 2011Main ParticularsLength, o.a. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229m Length, b.p. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .217.1m Breadth, molded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32.3m Depth, molded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34.7m Draft, designed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.3m Draft, scantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11.3m Deadweight at design draft . . . . . . . . . . . . . . . . . . . . . . . .22,260MT Deadweight at scantling draft . . . . . . . . . . . . . . . . . . . . .28,830 MT Main engine . . . . . . . . . . . . . . . . . . . . .Hyundai-B&W 8S60ME-C8 Ship's speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20.3 knots Shipbuilder...Daewoo Shipbuilding & Marine Engineering Co., Ltd. Owner/Operator...............................Oman Shipping Company(OSC) Flag........................................................................................MALTA IMO number..........................................................................9500716 Length o.a./b.p.................................................................333m/320m Breadth, molded...........................................................................60m Depth molded to main deck......................................................30.5m Draft, scantling/design......................................................22.5m/21m Gross.......................................................................................164,350 DWT, design/scantling.................................290,800MT/318,000MT Speed, service (85 %MCR output)...15.6 knots at the scantling draft Cargo capacity, Liquid volume....................................356,000 cu. m. Daily fuel consumption (tons/day) Main engine only................104.2 Classification..............................................................................DNV Main engine(s)..................................................Wärtsila 7RT-flex82T Cargo cranes/cargo gear............................................Cargotec, 20 ton Cargo tanks......................................................................................15 Cargo pumps...............3 x Shinko, 5,500 cu. m./h x 150 mTH (each) Cargo control system ...........................................Nakakita, Emerson Water ballast Treatment System.....OceanSaver; 2 sets x 4,000 m3/h Complement....................................................................................46 Bridge control system........................................................Kongsberg Fire detection system..........................................................Consilium Radars/IBS.........................................................................Kongsberg Waste compactor..........................................LOIPART, Model IP500 MR Dec.11 # 4 (25-33):MR Template 12/7/2011 10:55 AM Page 28

27

27

29

29