Page 35: of Maritime Reporter Magazine (January 2012)

US Navy Report

Read this page in Pdf, Flash or Html5 edition of January 2012 Maritime Reporter Magazine

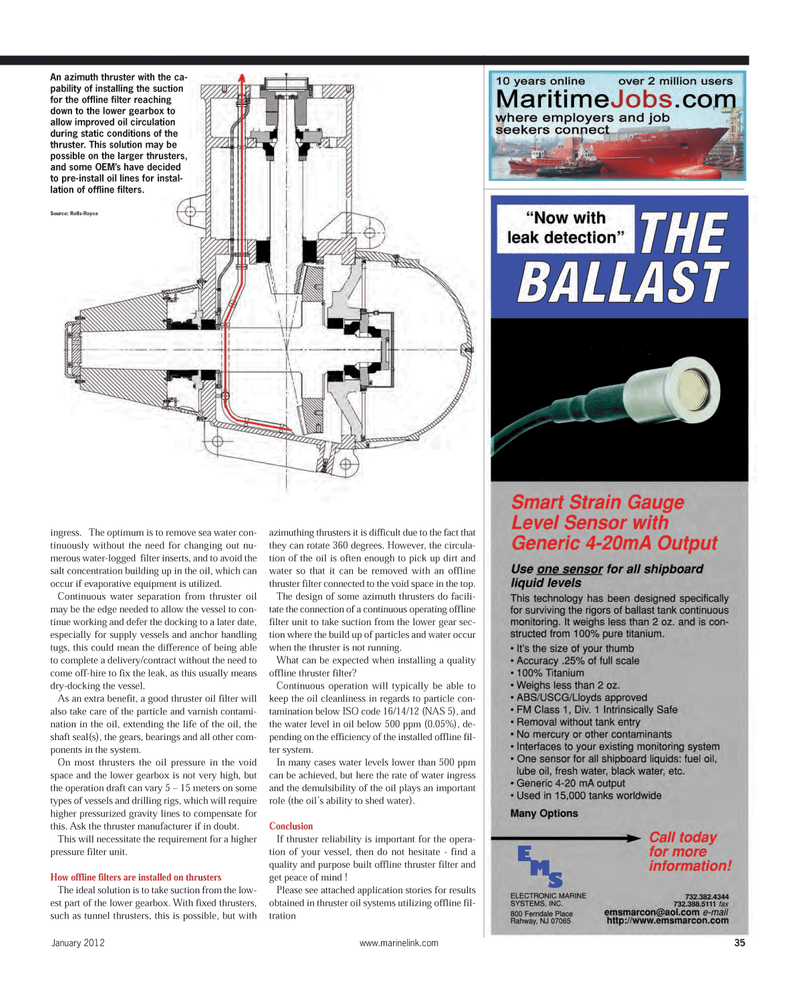

January 2012www.marinelink.com 35ingress. The optimum is to remove sea water con- tinuously without the need for changing out nu-merous water-logged filter inserts, and to avoid the salt concentration building up in the oil, which can occur if evaporative equipment is utilized. Continuous water separation from thruster oil may be the edge needed to allow the vessel to con- tinue working and defer the docking to a later date, especially for supply vessels and anchor handling tugs, this could mean the difference of being able to complete a delivery/contract without the need to come off-hire to fix the leak, as this usually means dry-docking the vessel. As an extra benefit, a good thruster oil filter will also take care of the particle and varnish contami- nation in the oil, extending the life of the oil, the shaft seal(s), the gears, bearings and all other com-ponents in the system.On most thrusters the oil pressure in the void space and the lower gearbox is not very high, but the operation draft can vary 5 ? 15 meters on some types of vessels and drilling rigs, which will require higher pressurized gravity lines to compensate for this. Ask the thruster manufacturer if in doubt. This will necessitate the requirement for a higherpressure filter unit. How offline filters are installed on thrusters The ideal solution is to take suction from the low- est part of the lower gearbox. With fixed thrusters, such as tunnel thrusters, this is possible, but with azimuthing thrusters it is difficult due to the fact that they can rotate 360 degrees. However, the circula- tion of the oil is often enough to pick up dirt andwater so that it can be removed with an offline thruster filter connected to the void space in the top. The design of some azimuth thrusters do facili- tate the connection of a continuous operating offline filter unit to take suction from the lower gear sec- tion where the build up of particles and water occur when the thruster is not running.What can be expected when installing a quality offline thruster filter? Continuous operation will typically be able tokeep the oil cleanliness in regards to particle con- tamination below ISO code 16/14/12 (NAS 5), and the water level in oil below 500 ppm (0.05%), de- pending on the efficiency of the installed offline fil- ter system.In many cases water levels lower than 500 ppm can be achieved, but here the rate of water ingress and the demulsibility of the oil plays an importantrole (the oil?s ability to shed water). ConclusionIf thruster reliability is important for the opera- tion of your vessel, then do not hesitate - find a quality and purpose built offline thruster filter and get peace of mind !Please see attached application stories for resultsobtained in thruster oil systems utilizing offline fil- tration An azimuth thruster with the ca-pability of installing the suctionfor the offline filter reaching down to the lower gearbox toallow improved oil circulation during static conditions of thethruster. This solution may be possible on the larger thrusters, and some OEM?s have decided to pre-install oil lines for instal- lation of offline filters. Source: Rolls-Royce MR Jan.12 # 5 (34-41):MR Template 1/10/2012 10:46 AM Page 35

34

34

36

36