Page 40: of Maritime Reporter Magazine (February 2012)

Cruise Shipping Annual

Read this page in Pdf, Flash or Html5 edition of February 2012 Maritime Reporter Magazine

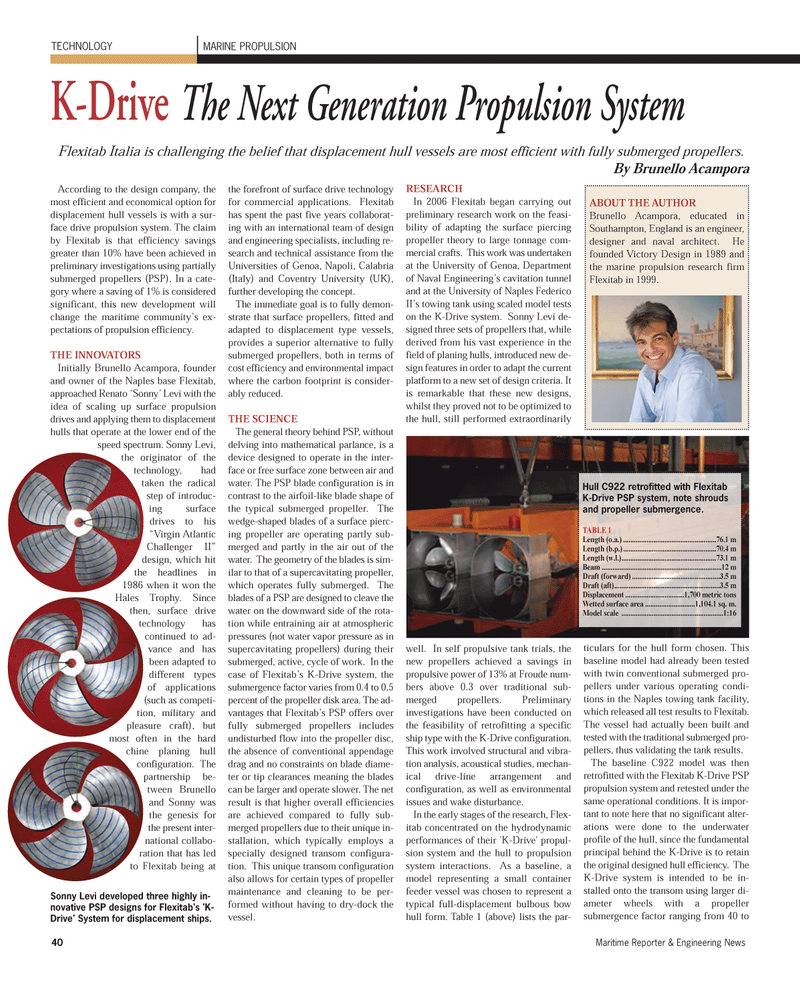

TECHNOLOGYMARINE PROPULSION40Maritime Reporter & Engineering News According to the design company, the most efficient and economical option for displacement hull vessels is with a sur- face drive propulsion system. The claim by Flexitab is that efficiency savings greater than 10% have been achieved in preliminary investigations using partially submerged propellers (PSP). In a cate- gory where a saving of 1% is considered significant, this new development will change the maritime community?s ex- pectations of propulsion efficiency. THE INNOVATORS Initially Brunello Acampora, founder and owner of the Naples base Flexitab, approached Renato ?Sonny? Levi with the idea of scaling up surface propulsion drives and applying them to displacement hulls that operate at the lower end of the speed spectrum. Sonny Levi, the originator of thetechnology, had taken the radical step of introduc-ing surface drives to his ?Virgin Atlantic Challenger II?design, which hitthe headlines in1986 when it won the Hales Trophy. Since then, surface drive technology hascontinued to ad-vance and has been adapted todifferent types of applications(such as competi-tion, military andpleasure craft), but most often in the hardchine planing hullconfiguration. The partnership be-tween Brunelloand Sonny was the genesis forthe present inter- national collabo-ration that has ledto Flexitab being at the forefront of surface drive technology for commercial applications. Flexitab has spent the past five years collaborat- ing with an international team of designand engineering specialists, including re-search and technical assistance from theUniversities of Genoa, Napoli, Calabria (Italy) and Coventry University (UK), further developing the concept. The immediate goal is to fully demon-strate that surface propellers, fitted and adapted to displacement type vessels, provides a superior alternative to fully submerged propellers, both in terms of cost efficiency and environmental impact where the carbon footprint is consider- ably reduced.THE SCIENCEThe general theory behind PSP, without delving into mathematical parlance, is adevice designed to operate in the inter- face or free surface zone between air and water. The PSP blade configuration is in contrast to the airfoil-like blade shape of the typical submerged propeller. The wedge-shaped blades of a surface pierc- ing propeller are operating partly sub-merged and partly in the air out of the water. The geometry of the blades is sim- ilar to that of a supercavitating propeller, which operates fully submerged. The blades of a PSP are designed to cleave the water on the downward side of the rota- tion while entraining air at atmosphericpressures (not water vapor pressure as in supercavitating propellers) during their submerged, active, cycle of work. In the case of Flexitab?s K-Drive system, the submergence factor varies from 0.4 to 0.5 percent of the propeller disk area. The ad- vantages that Flexitab?s PSP offers over fully submerged propellers includes undisturbed flow into the propeller disc, the absence of conventional appendage drag and no constraints on blade diame-ter or tip clearances meaning the bladescan be larger and operate slower. The net result is that higher overall efficiencies are achieved compared to fully sub- merged propellers due to their unique in- stallation, which typically employs a specially designed transom configura- tion. This unique transom configuration also allows for certain types of propeller maintenance and cleaning to be per- formed without having to dry-dock the vessel. RESEARCHIn 2006 Flexitab began carrying out preliminary research work on the feasi-bility of adapting the surface piercing propeller theory to large tonnage com- mercial crafts. This work was undertaken at the University of Genoa, Department of Naval Engineering?s cavitation tunnel and at the University of Naples Federico II?s towing tank using scaled model tests on the K-Drive system. Sonny Levi de- signed three sets of propellers that, whilederived from his vast experience in the field of planing hulls, introduced new de- sign features in order to adapt the currentplatform to a new set of design criteria. It is remarkable that these new designs, whilst they proved not to be optimized to the hull, still performed extraordinarily well. In self propulsive tank trials, the new propellers achieved a savings in propulsive power of 13% at Froude num- bers above 0.3 over traditional sub- merged propellers. Preliminary investigations have been conducted on the feasibility of retrofitting a specific ship type with the K-Drive configuration. This work involved structural and vibra- tion analysis, acoustical studies, mechan-ical drive-line arrangement and configuration, as well as environmental issues and wake disturbance. In the early stages of the research, Flex- itab concentrated on the hydrodynamic performances of their 'K-Drive' propul- sion system and the hull to propulsionsystem interactions. As a baseline, a model representing a small containerfeeder vessel was chosen to represent a typical full-displacement bulbous bow hull form. Table 1 (above) lists the par- ticulars for the hull form chosen. This baseline model had already been testedwith twin conventional submerged pro- pellers under various operating condi- tions in the Naples towing tank facility, which released all test results to Flexitab. The vessel had actually been built and tested with the traditional submerged pro- pellers, thus validating the tank results. The baseline C922 model was then retrofitted with the Flexitab K-Drive PSP propulsion system and retested under thesame operational conditions. It is impor- tant to note here that no significant alter- ations were done to the underwater profile of the hull, since the fundamental principal behind the K-Drive is to retain the original designed hull efficiency. The K-Drive system is intended to be in- stalled onto the transom using larger di- ameter wheels with a propellersubmergence factor ranging from 40 to K-Drive The Next Generation Propulsion System Flexitab Italia is challenging the belief that displacement hull vessels are most efficient with fully submerged propellers. By Brunello Acampora ABOUT THE AUTHOR Brunello Acampora, educated in Southampton, England is an engineer,designer and naval architect. He founded Victory Design in 1989 and the marine propulsion research firm Flexitab in 1999. Hull C922 retrofitted with Flexitab K-Drive PSP system, note shrouds and propeller submergence. TABLE 1 Length (o.a.)....................................................76.1 m Length (b.p.)....................................................70.4 mLength (w.l.).....................................................73.1 m Beam...................................................................12 m Draft (forward).................................................3.5 m Draft (aft)...........................................................3.5 m Displacement.................................1,700 metric tons Wetted surface area............................1,104.1 sq. m. Model scale .........................................................1:16 Sonny Levi developed three highly in- novative PSP designs for Flexitab's 'K-Drive' System for displacement ships.MR Feb.12 # 5 (34-41):MR Template 2/7/2012 10:40 AM Page 40

39

39

41

41