Page 46: of Maritime Reporter Magazine (April 2012)

Offshore Deepwater Annual

Read this page in Pdf, Flash or Html5 edition of April 2012 Maritime Reporter Magazine

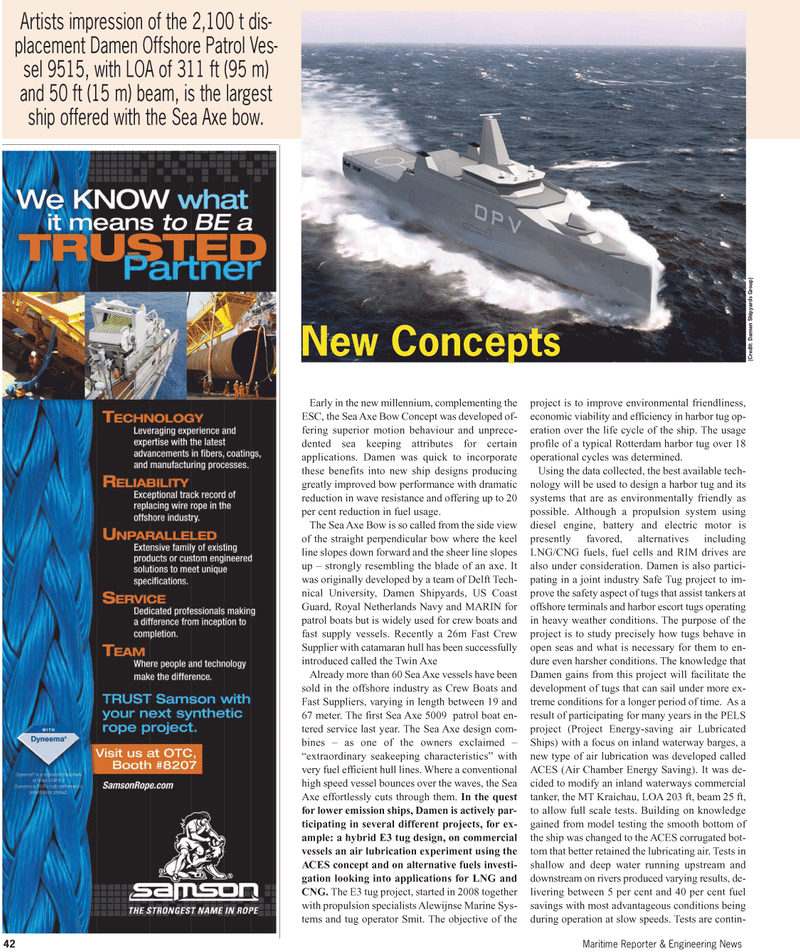

Early in the new millennium, complementing the ESC, the Sea Axe Bow Concept was developed of- fering superior motion behaviour and unprece- dented sea keeping attributes for certain applications. Damen was quick to incorporate these benefits into new ship designs producing greatly improved bow performance with dramatic reduction in wave resistance and offering up to 20 per cent reduction in fuel usage.The Sea Axe Bow is so called from the side view of the straight perpendicular bow where the keel line slopes down forward and the sheer line slopes up ? strongly resembling the blade of an axe. It was originally developed by a team of Delft Tech- nical University, Damen Shipyards, US Coast Guard, Royal Netherlands Navy and MARIN for patrol boats but is widely used for crew boats and fast supply vessels. Recently a 26m Fast Crew Supplier with catamaran hull has been successfullyintroduced called the Twin Axe Already more than 60 Sea Axe vessels have been sold in the offshore industry as Crew Boats and Fast Suppliers, varying in length between 19 and 67 meter. The first Sea Axe 5009 patrol boat en- tered service last year. The Sea Axe design com- bines ? as one of the owners exclaimed ? extraordinary seakeeping characteristics? with very fuel efficient hull lines. Where a conventional high speed vessel bounces over the waves, the Sea Axe effortlessly cuts through them. In the questfor lower emission ships, Damen is actively par- ticipating in several different projects, for ex- ample: a hybrid E3 tug design, on commercial vessels an air lubrication experiment using the ACES concept and on alternative fuels investi- gation looking into applications for LNG and CNG. The E3 tug project, started in 2008 togetherwith propulsion specialists Alewijnse Marine Sys- tems and tug operator Smit. The objective of the project is to improve environmental friendliness, economic viability and efficiency in harbor tug op- eration over the life cycle of the ship. The usage profile of a typical Rotterdam harbor tug over 18 operational cycles was determined. Using the data collected, the best available tech- nology will be used to design a harbor tug and itssystems that are as environmentally friendly as possible. Although a propulsion system using diesel engine, battery and electric motor ispresently favored, alternatives including LNG/CNG fuels, fuel cells and RIM drives are also under consideration. Damen is also partici- pating in a joint industry Safe Tug project to im- prove the safety aspect of tugs that assist tankers at offshore terminals and harbor escort tugs operating in heavy weather conditions. The purpose of the project is to study precisely how tugs behave in open seas and what is necessary for them to en-dure even harsher conditions. The knowledge that Damen gains from this project will facilitate the development of tugs that can sail under more ex- treme conditions for a longer period of time. As a result of participating for many years in the PELS project (Project Energy-saving air Lubricated Ships) with a focus on inland waterway barges, a new type of air lubrication was developed called ACES (Air Chamber Energy Saving). It was de- cided to modify an inland waterways commercial tanker, the MT Kraichau, LOA 203 ft, beam 25 ft, to allow full scale tests. Building on knowledge gained from model testing the smooth bottom of the ship was changed to the ACES corrugated bot- tom that better retained the lubricating air. Tests in shallow and deep water running upstream and downstream on rivers produced varying results, de- livering between 5 per cent and 40 per cent fuel savings with most advantageous conditions being during operation at slow speeds. Tests are contin- 42Maritime Reporter & Engineering News Artists impression of the 2,100 t dis- placement Damen Offshore Patrol Ves- sel 9515, with LOA of 311 ft (95 m)and 50 ft (15 m) beam, is the largest ship offered with the Sea Axe bow. New Concepts(Credit: Damen Shipyards Group)

45

45

47

47