Page 32: of Maritime Reporter Magazine (September 2012)

Marine Propulsion Annual

Read this page in Pdf, Flash or Html5 edition of September 2012 Maritime Reporter Magazine

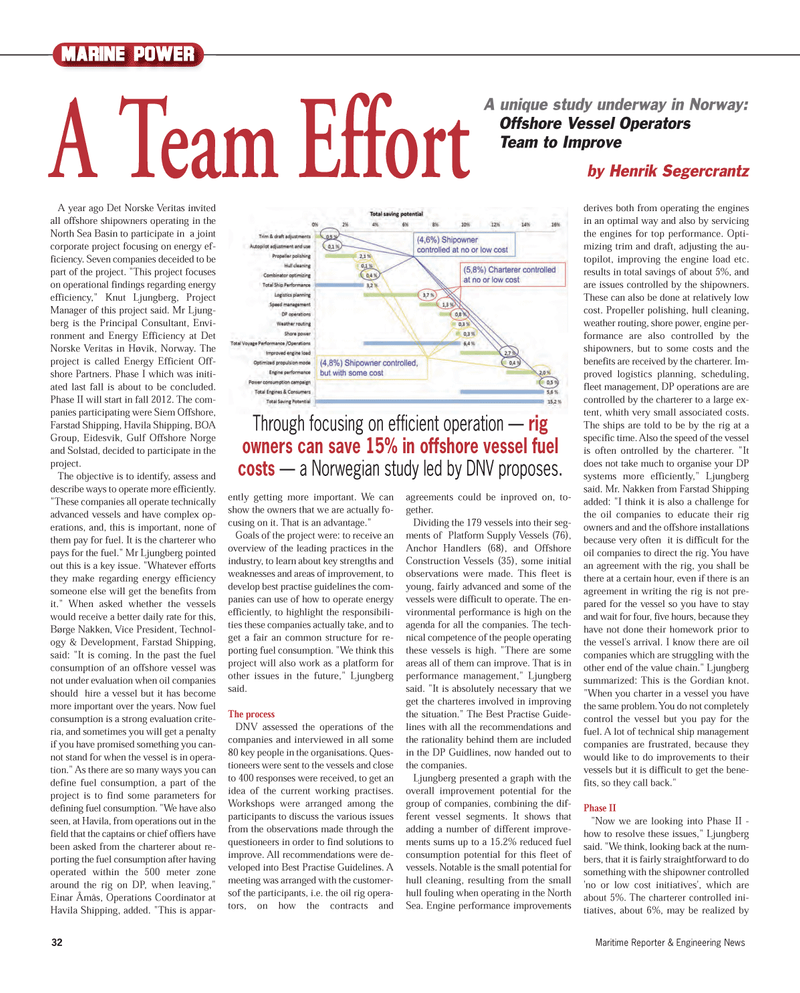

32Maritime Reporter & Engineering News A year ago Det Norske Veritas invited all offshore shipowners operating in the North Sea Basin to participate in a jointcorporate project focusing on energy ef- ficiency. Seven companies deceided to be part of the project. "This project focuseson operational findings regarding energy efficiency," Knut Ljungberg, Project Manager of this project said. Mr Ljung-berg is the Principal Consultant, Envi- ronment and Energy Efficiency at Det Norske Veritas in Høvik, Norway. The project is called Energy Efficient Off- shore Partners. Phase I which was initi- ated last fall is about to be concluded. Phase II will start in fall 2012. The com- panies participating were Siem Offshore, Farstad Shipping, Havila Shipping, BOA Group, Eidesvik, Gulf Offshore Norge and Solstad, decided to participate in theproject. The objective is to identify, assess and describe ways to operate more efficiently. "These companies all operate technicallyadvanced vessels and have complex op- erations, and, this is important, none ofthem pay for fuel. It is the charterer whopays for the fuel." Mr Ljungberg pointed out this is a key issue. "Whatever efforts they make regarding energy efficiency someone else will get the benefits from it." When asked whether the vessels would receive a better daily rate for this, Børge Nakken, Vice President, Technol- ogy & Development, Farstad Shipping, said: "It is coming. In the past the fuelconsumption of an offshore vessel was not under evaluation when oil companies should hire a vessel but it has become more important over the years. Now fuel consumption is a strong evaluation crite- ria, and sometimes you will get a penaltyif you have promised something you can- not stand for when the vessel is in opera- tion." As there are so many ways you can define fuel consumption, a part of the project is to find some parameters for defining fuel consumption. "We have also seen, at Havila, from operations out in the field that the captains or chief offiers have been asked from the charterer about re- porting the fuel consumption after having operated within the 500 meter zonearound the rig on DP, when leaving," Einar Åmås, Operations Coordinator atHavila Shipping, added. "This is appar- ently getting more important. We can show the owners that we are actually fo- cusing on it. That is an advantage." Goals of the project were: to receive an overview of the leading practices in the industry, to learn about key strengths and weaknesses and areas of improvement, to develop best practise guidelines the com- panies can use of how to operate energy efficiently, to highlight the responsibili- ties these companies actually take, and to get a fair an common structure for re- porting fuel consumption. "We think this project will also work as a platform for other issues in the future," Ljungberg said.The process DNV assessed the operations of thecompanies and interviewed in all some 80 key people in the organisations. Ques- tioneers were sent to the vessels and close to 400 responses were received, to get an idea of the current working practises. Workshops were arranged among the participants to discuss the various issues from the observations made through the questioneers in order to find solutions to improve. All recommendations were de- veloped into Best Practise Guidelines. A meeting was arranged with the customer- sof the participants, i.e. the oil rig opera- tors, on how the contracts and agreements could be inproved on, to- gether. Dividing the 179 vessels into their seg- ments of Platform Supply Vessels (76), Anchor Handlers (68), and Offshore Construction Vessels (35), some initial observations were made. This fleet is young, fairly advanced and some of the vessels were difficult to operate. The en- vironmental performance is high on theagenda for all the companies. The tech- nical competence of the people operatingthese vessels is high. "There are some areas all of them can improve. That is in performance management," Ljungberg said. "It is absolutely necessary that weget the charteres involved in improving the situation." The Best Practise Guide- lines with all the recommendations andthe rationality behind them are includedin the DP Guidlines, now handed out to the companies.Ljungberg presented a graph with the overall improvement potential for the group of companies, combining the dif-ferent vessel segments. It shows that adding a number of different improve- ments sums up to a 15.2% reduced fuelconsumption potential for this fleet ofvessels. Notable is the small potential for hull cleaning, resulting from the smallhull fouling when operating in the NorthSea. Engine performance improvements derives both from operating the engines in an optimal way and also by servicing the engines for top performance. Opti-mizing trim and draft, adjusting the au-topilot, improving the engine load etc. results in total savings of about 5%, and are issues controlled by the shipowners. These can also be done at relatively low cost. Propeller polishing, hull cleaning,weather routing, shore power, engine per- formance are also controlled by theshipowners, but to some costs and the benefits are received by the charterer. Im- proved logistics planning, scheduling, fleet management, DP operations are arecontrolled by the charterer to a large ex- tent, whith very small associated costs. The ships are told to be by the rig at aspecific time. Also the speed of the vessel is often ontrolled by the charterer. "It does not take much to organise your DP systems more efficiently," Ljungberg said. Mr. Nakken from Farstad Shipping added: "I think it is also a challenge forthe oil companies to educate their rigowners and and the offshore installations because very often it is difficult for the oil companies to direct the rig. You have an agreement with the rig, you shall bethere at a certain hour, even if there is an agreement in writing the rig is not pre-pared for the vessel so you have to stay and wait for four, five hours, because they have not done their homework prior to the vessel's arrival. I know there are oil companies which are struggling with theother end of the value chain." Ljungberg summarized: This is the Gordian knot. "When you charter in a vessel you have the same problem. You do not completely control the vessel but you pay for the fuel. A lot of technical ship management companies are frustrated, because they would like to do improvements to their vessels but it is difficult to get the bene- fits, so they call back." Phase II"Now we are looking into Phase II - how to resolve these issues," Ljungberg said. "We think, looking back at the num- bers, that it is fairly straightforward to do something with the shipowner controlled 'no or low cost initiatives', which are about 5%. The charterer controlled ini- tiatives, about 6%, may be realized by Marine PowerA unique study underway in Norway: Offshore Vessel Operators Team to Improve by Henrik Segercrantz Through focusing on efficient operation ? rig owners can save 15% in offshore vessel fuel costs ? a Norwegian study led by DNV proposes. A Team Effort MR#9 (26-33):MR Template 9/11/2012 1:57 PM Page 32

31

31

33

33