Page 24: of Maritime Reporter Magazine (January 2013)

Ship Repair & Conversion

Read this page in Pdf, Flash or Html5 edition of January 2013 Maritime Reporter Magazine

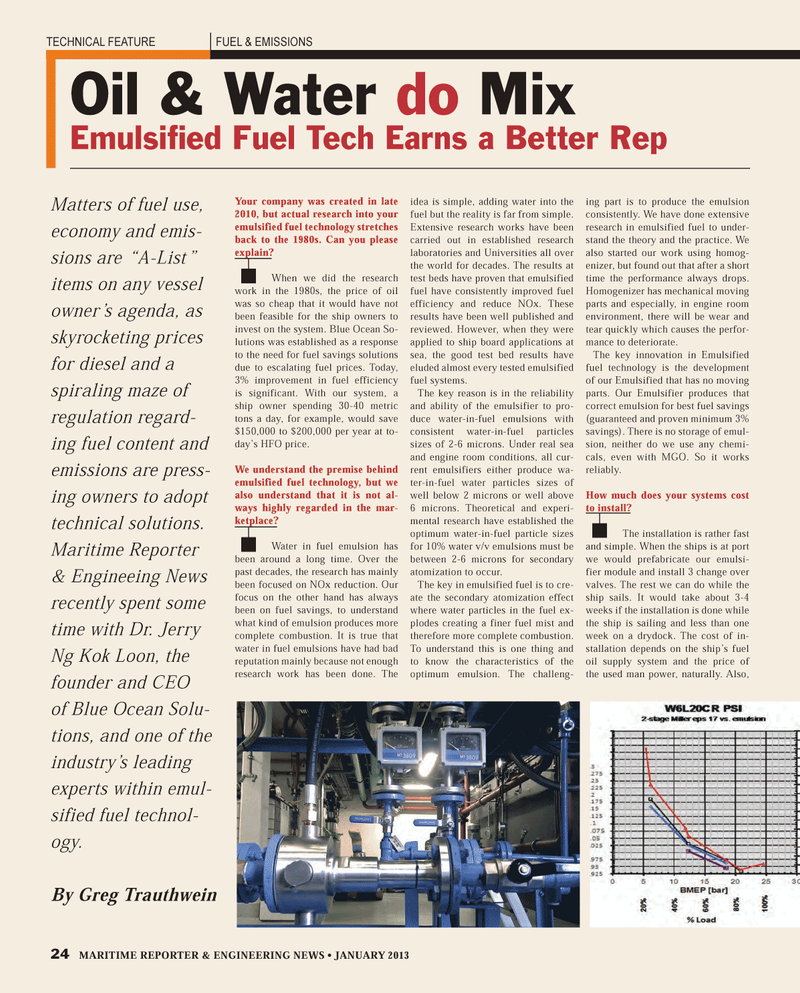

Your company was created in late 2010, but actual research into your emulsified fuel technology stretches back to the 1980s. Can you please explain? When we did the research work in the 1980s, the price of oil was so cheap that it would have not been feasible for the ship owners to invest on the system. Blue Ocean So-lutions was established as a response to the need for fuel savings solutions due to escalating fuel prices. Today, 3% improvement in fuel efficiency is significant. With our system, a ship owner spending 30-40 metric tons a day, for example, would save $150,000 to $200,000 per year at to-day?s HFO price. We understand the premise behind emulsified fuel technology, but we also understand that it is not al-ways highly regarded in the mar- ketplace? Water in fuel emulsion has been around a long time. Over the past decades, the research has mainly been focused on NOx reduction. Our focus on the other hand has always been on fuel savings, to understand what kind of emulsion produces more complete combustion. It is true that water in fuel emulsions have had bad reputation mainly because not enough research work has been done. The idea is simple, adding water into the fuel but the reality is far from simple. Extensive research works have been carried out in established research laboratories and Universities all over the world for decades. The results at test beds have proven that emulsified fuel have consistently improved fuel efficiency and reduce NOx. These results have been well published and reviewed. However, when they were applied to ship board applications at sea, the good test bed results have eluded almost every tested emulsified fuel systems. The key reason is in the reliability and ability of the emulsifier to pro-duce water-in-fuel emulsions with consistent water-in-fuel particles sizes of 2-6 microns. Under real sea and engine room conditions, all cur- rent emulsifiers either produce wa-ter-in-fuel water particles sizes of well below 2 microns or well above 6 microns. Theoretical and experi- mental research have established the optimum water-in-fuel particle sizes for 10% water v/v emulsions must be between 2-6 microns for secondary atomization to occur. The key in emulsified fuel is to cre-ate the secondary atomization effect where water particles in the fuel ex-plodes creating a finer fuel mist and therefore more complete combustion. To understand this is one thing and to know the characteristics of the optimum emulsion. The challeng- ing part is to produce the emulsion consistently. We have done extensive research in emulsified fuel to under- stand the theory and the practice. We also started our work using homog-enizer, but found out that after a short time the performance always drops. Homogenizer has mechanical moving parts and especially, in engine room environment, there will be wear and tear quickly which causes the perfor- mance to deteriorate.The key innovation in Emulsified fuel technology is the development of our Emulsified that has no moving parts. Our Emulsifier produces that correct emulsion for best fuel savings (guaranteed and proven minimum 3% savings). There is no storage of emul- sion, neither do we use any chemi-cals, even with MGO. So it works reliably. How much does your systems cost to install? The installation is rather fast and simple. When the ships is at port we would prefabricate our emulsi-fier module and install 3 change over valves. The rest we can do while the ship sails. It would take about 3-4 weeks if the installation is done while the ship is sailing and less than one week on a drydock. The cost of in- stallation depends on the ship?s fuel oil supply system and the price of the used man power, naturally. Also, TECHNICAL FEATURE FUEL & EMISSIONS Oil & Water do MixEmulsiÞ ed Fuel Tech Earns a Better Rep Matters of fuel use, economy and emis-sions are ?A-List? items on any vessel owner?s agenda, as skyrocketing prices for diesel and a spiraling maze of regulation regard- ing fuel content and emissions are press- ing owners to adopt technical solutions. Maritime Reporter & Engineeing News recently spent some time with Dr. Jerry Ng Kok Loon, the founder and CEO of Blue Ocean Solu-tions, and one of the industry?s leading experts within emul-sified fuel technol-ogy. By Greg Trauthwein 24 MARITIME REPORTER & ENGINEERING NEWS ? JANUARY 2013 MR #1 (18-25).indd 24MR #1 (18-25).indd 241/2/2013 11:01:24 AM1/2/2013 11:01:24 AM

23

23

25

25