Page 34: of Maritime Reporter Magazine (April 2013)

Offshore Energy Edition

Read this page in Pdf, Flash or Html5 edition of April 2013 Maritime Reporter Magazine

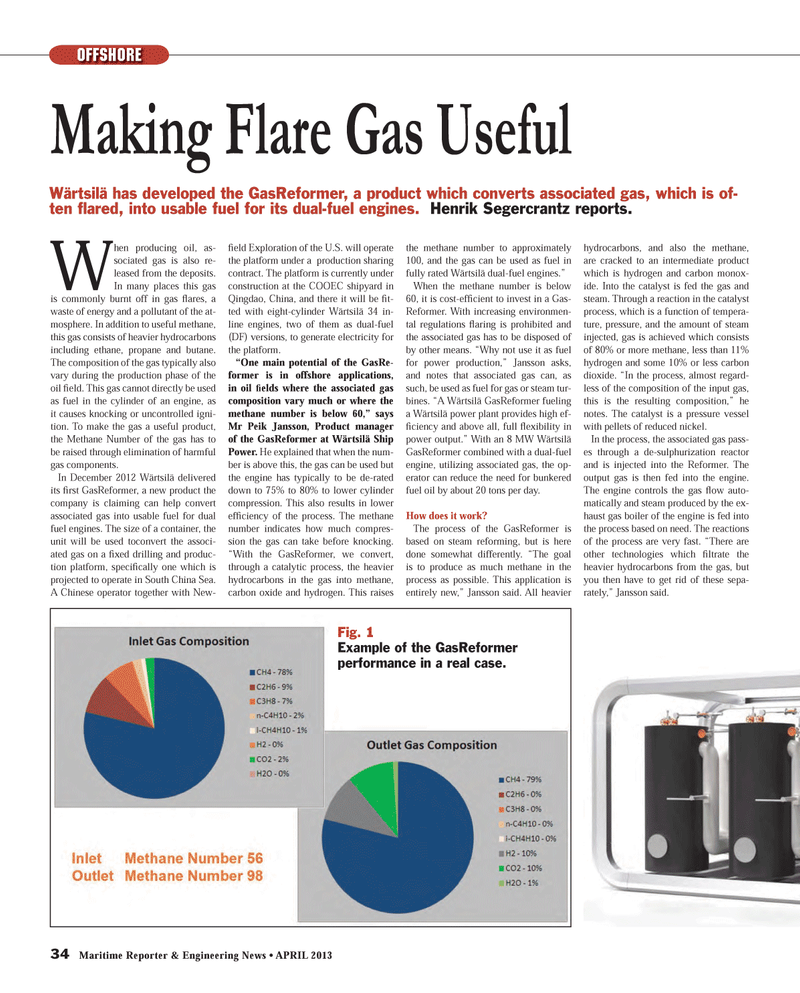

34 Maritime Reporter & Engineering News ? APRIL 2013 When producing oil, as-sociated gas is also re-leased from the deposits. In many places this gas is commonly burnt off in gas ß ares, a waste of energy and a pollutant of the at- mosphere. In addition to useful methane, this gas consists of heavier hydrocarbons including ethane, propane and butane. The composition of the gas typically also vary during the production phase of the oil Þ eld. This gas cannot directly be used as fuel in the cylinder of an engine, as it causes knocking or uncontrolled igni-tion. To make the gas a useful product, the Methane Number of the gas has to be raised through elimination of harmful gas components. In December 2012 Wärtsilä delivered its Þ rst GasReformer, a new product the company is claiming can help convert associated gas into usable fuel for dual fuel engines. The size of a container, the unit will be used toconvert the associ-ated gas on a Þ xed drilling and produc- tion platform, speciÞ cally one which is projected to operate in South China Sea. A Chinese operator together with New- Þ eld Exploration of the U.S. will operate the platform under a production sharing contract. The platform is currently under construction at the COOEC shipyard in Qingdao, China, and there it will be Þ t-ted with eight-cylinder Wärtsilä 34 in- line engines, two of them as dual-fuel (DF) versions, to generate electricity for the platform.?One main potential of the GasRe-former is in offshore applications, in oil Þ elds where the associated gas composition vary much or where the methane number is below 60,? says Mr Peik Jansson, Product manager of the GasReformer at Wärtsilä Ship Power. He explained that when the num-ber is above this, the gas can be used but the engine has typically to be de-rated down to 75% to 80% to lower cylinder compression. This also results in lower efÞ ciency of the process. The methane number indicates how much compres-sion the gas can take before knocking. ?With the GasReformer, we convert, through a catalytic process, the heavier hydrocarbons in the gas into methane, carbon oxide and hydrogen. This raises the methane number to approximately 100, and the gas can be used as fuel in fully rated Wärtsilä dual-fuel engines.? When the methane number is below 60, it is cost-efÞ cient to invest in a Gas-Reformer. With increasing environmen- tal regulations ß aring is prohibited and the associated gas has to be disposed of by other means. ?Why not use it as fuel for power production,? Jansson asks, and notes that associated gas can, as such, be used as fuel for gas or steam tur- bines. ?A Wärtsilä GasReformer fueling a Wärtsilä power plant provides high ef- Þ ciency and above all, full ß exibility in power output.? With an 8 MW Wärtsilä GasReformer combined with a dual-fuel engine, utilizing associated gas, the op-erator can reduce the need for bunkered fuel oil by about 20 tons per day. How does it work?The process of the GasReformer is based on steam reforming, but is here done somewhat differently. ?The goal is to produce as much methane in the process as possible. This application is entirely new,? Jansson said. All heavier hydrocarbons, and also the methane, are cracked to an intermediate product which is hydrogen and carbon monox-ide. Into the catalyst is fed the gas and steam. Through a reaction in the catalyst process, which is a function of tempera-ture, pressure, and the amount of steam injected, gas is achieved which consists of 80% or more methane, less than 11% hydrogen and some 10% or less carbon dioxide. ?In the process, almost regard-less of the composition of the input gas, this is the resulting composition,? he notes. The catalyst is a pressure vessel with pellets of reduced nickel.In the process, the associated gas pass-es through a de-sulphurization reactor and is injected into the Reformer. The output gas is then fed into the engine. The engine controls the gas ß ow auto- matically and steam produced by the ex-haust gas boiler of the engine is fed into the process based on need. The reactions of the process are very fast. ?There are other technologies which Þ ltrate the heavier hydrocarbons from the gas, but you then have to get rid of these sepa-rately,? Jansson said. OFFSHOREMaking Flare Gas Useful Wärtsilä has developed the GasReformer, a product which converts associated gas, which is of- ten ared, into usable fuel for its dual-fuel engines. Henrik Segercrantz reports. Fig. 1Example of the GasReformer performance in a real case.MR #4 (34-41).indd 34MR #4 (34-41).indd 344/5/2013 9:23:00 AM4/5/2013 9:23:00 AM

33

33

35

35