Page 48: of Maritime Reporter Magazine (November 2013)

Marine Propulsion Annual

Read this page in Pdf, Flash or Html5 edition of November 2013 Maritime Reporter Magazine

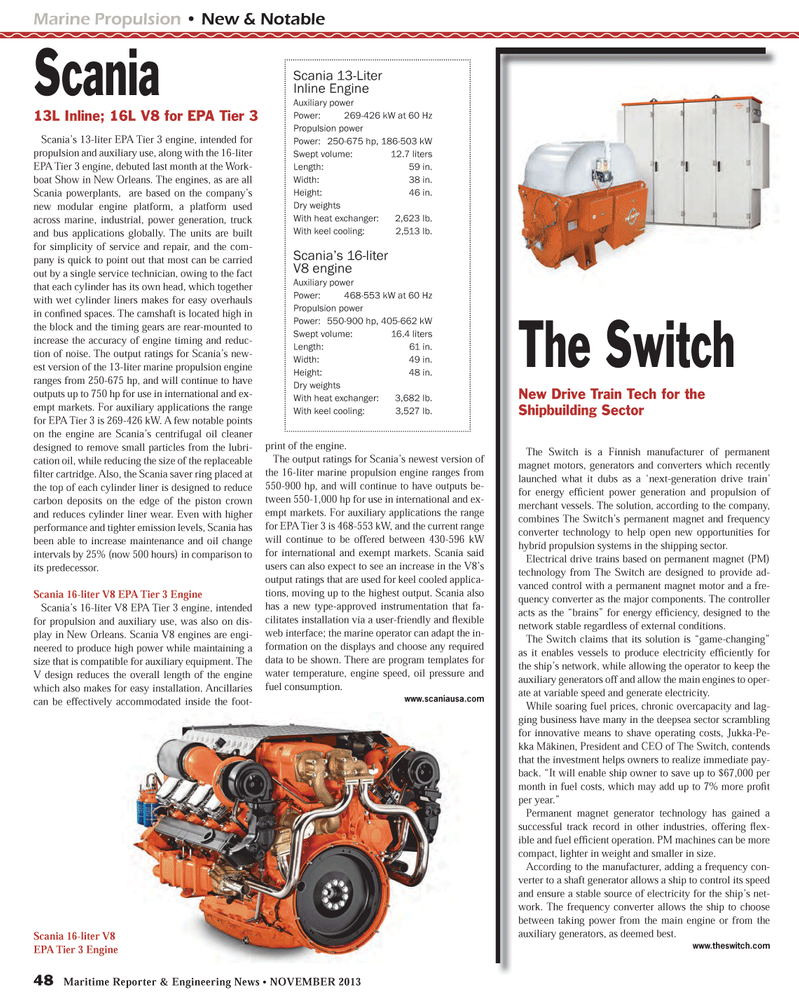

48 Maritime Reporter & Engineering News ? NOVEMBER 2013 Marine Propulsion ? New & NotableThe Switch New Drive Train Tech for the Shipbuilding SectorThe Switch is a Finnish manufacturer of permanent magnet motors, generators and converters which recently launched what it dubs as a ?next-generation drive train? for energy ef Þ cient power generation and propulsion of merchant vessels. The solution, according to the company, combines The Switch?s permanent magnet and frequency converter technology to help open new opportunities for hybrid propulsion systems in the shipping sector. Electrical drive trains based on permanent magnet (PM) technology from The Switch are designed to provide ad- vanced control with a permanent magnet motor and a fre-quency converter as the major components. The controller acts as the ?brains? for energy ef Þ ciency, designed to the network stable regardless of external conditions.The Switch claims that its solution is ?game-changing? as it enables vessels to produce electricity efÞ ciently for the ship?s network, while allowing the operator to keep the auxiliary generators off and allow the main engines to oper- ate at variable speed and generate electricity. While soaring fuel prices, chronic overcapacity and lag-ging business have many in the deepsea sector scrambling for innovative means to shave operating costs, Jukka-Pe-kka Mäkinen, President and CEO of The Switch, contends that the investment helps owners to realize immediate pay-back. ?It will enable ship owner to save up to $67,000 per month in fuel costs, which may add up to 7% more proÞ t per year.? Permanent magnet generator technology has gained a successful track record in other industries, offering ß ex-ible and fuel efÞ cient operation. PM machines can be more compact, lighter in weight and smaller in size. According to the manufacturer, adding a frequency con- verter to a shaft generator allows a ship to control its speed and ensure a stable source of electricity for the ship?s net- work. The frequency converter allows the ship to choose between taking power from the main engine or from the auxiliary generators, as deemed best.www.theswitch.com Scania?s 13-liter EPA Tier 3 engine, intended for propulsion and auxiliary use, along with the 16-liter EPA Tier 3 engine, debuted last month at the Work- boat Show in New Orleans. The engines, as are all Scania powerplants, are based on the company?s new modular engine platform, a platform used across marine, industrial, power generation, truck and bus applications globally. The units are built for simplicity of service and repair, and the com- pany is quick to point out that most can be carried out by a single service technician, owing to the fact that each cylinder has its own head, which together with wet cylinder liners makes for easy overhauls in conÞ ned spaces. The camshaft is located high in the block and the timing gears are rear-mounted to increase the accuracy of engine timing and reduc-tion of noise. The output ratings for Scania?s new- est version of the 13-liter marine propulsion engine ranges from 250-675 hp, and will continue to have outputs up to 750 hp for use in international and ex-empt markets. For auxiliary applications the range for EPA Tier 3 is 269-426 kW. A few notable points on the engine are Scania?s centrifugal oil cleaner designed to remove small particles from the lubri-cation oil, while reducing the size of the replaceable Þ lter cartridge. Also, the Scania saver ring placed at the top of each cylinder liner is designed to reduce carbon deposits on the edge of the piston crown and reduces cylinder liner wear. Even with higher performance and tighter emission levels, Scania has been able to increase maintenance and oil change intervals by 25% (now 500 hours) in comparison to its predecessor. Scania 16-liter V8 EPA Tier 3 Engine Scania?s 16-liter V8 EPA Tier 3 engine, intended for propulsion and auxiliary use, was also on dis-play in New Orleans. Scania V8 engines are engi-neered to produce high power while maintaining a size that is compatible for auxiliary equipment. The V design reduces the overall length of the engine which also makes for easy installation. Ancillaries can be effectively accommodated inside the foot- print of the engine.The output ratings for Scania?s newest version of the 16-liter marine propulsion engine ranges from 550-900 hp, and will continue to have outputs be-tween 550-1,000 hp for use in international and ex-empt markets. For auxiliary applications the range for EPA Tier 3 is 468-553 kW, and the current range will continue to be offered between 430-596 kW for international and exempt markets. Scania said users can also expect to see an increase in the V8?s output ratings that are used for keel cooled applica-tions, moving up to the highest output. Scania also has a new type-approved instrumentation that fa-cilitates installation via a user-friendly and ß exible web interface; the marine operator can adapt the in-formation on the displays and choose any required data to be shown. There are program templates for water temperature, engine speed, oil pressure and fuel consumption.www.scaniausa.com Scania13L Inline; 16L V8 for EPA Tier 3 Scania 16-liter V8 EPA Tier 3 Engine Scania 13-Liter Inline EngineAuxiliary power Power: 269-426 kW at 60 Hz Propulsion power Power: 250-675 hp, 186-503 kW Swept volume: 12.7 liters Length: 59 in. Width: 38 in. Height: 46 in. Dry weights With heat exchanger: 2,623 Ib. With keel cooling: 2,513 Ib. Scania?s 16-liter V8 engineAuxiliary power Power: 468-553 kW at 60 Hz Propulsion power Power: 550-900 hp, 405-662 kW Swept volume: 16.4 liters Length: 61 in. Width: 49 in. Height: 48 in. Dry weights With heat exchanger: 3,682 Ib. With keel cooling: 3,527 Ib. MR #11 (42-49).indd 48MR #11 (42-49).indd 4811/12/2013 10:59:27 AM11/12/2013 10:59:27 AM

47

47

49

49