Page 46: of Maritime Reporter Magazine (February 2014)

Cruise Shipping Edition

Read this page in Pdf, Flash or Html5 edition of February 2014 Maritime Reporter Magazine

46 Maritime Reporter & Engineering News • FEBRUARY 2014

WATER TECHNOLOGY

T he global market for BWT systems is predicted to grow to over $34 billion through 2020 in response to IMO and

USCG-based ballast water discharge regulations (Frost and Sullivan, 2012). BWT sys- tems are now manufactured by dozens of compa- nies around the world, including traditional sup- pliers of marine equipment, suppliers of municipal water and wastewater treatment equipment, and shipbuilders. As of November 2013, 35 BWT sys- tems have received IMO-type approval from for- eign administrations, and 28 of these have been accepted into the AMS program by the USCG.

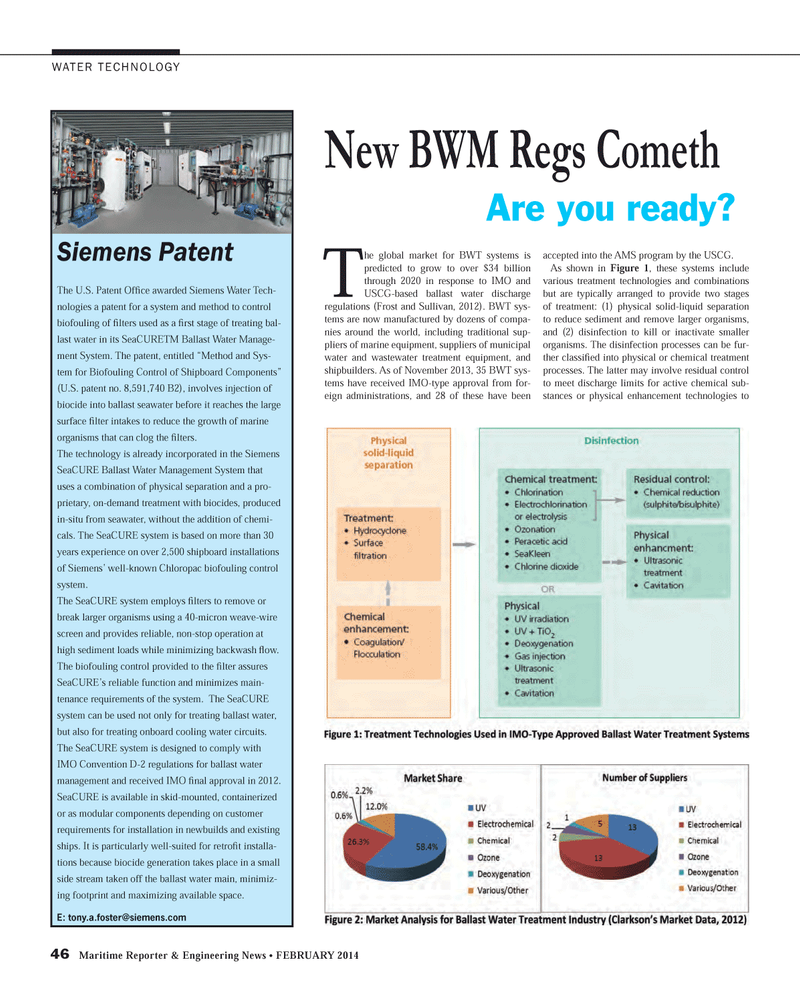

As shown in Figure 1, these systems include various treatment technologies and combinations but are typically arranged to provide two stages of treatment: (1) physical solid-liquid separation to reduce sediment and remove larger organisms, and (2) disinfection to kill or inactivate smaller organisms. The disinfection processes can be fur- ther classifi ed into physical or chemical treatment processes. The latter may involve residual control to meet discharge limits for active chemical sub- stances or physical enhancement technologies to

Siemens Patent

The U.S. Patent Offi ce awarded Siemens Water Tech- nologies a patent for a system and method to control biofouling of fi lters used as a fi rst stage of treating bal- last water in its SeaCURETM Ballast Water Manage- ment System. The patent, entitled “Method and Sys- tem for Biofouling Control of Shipboard Components” (U.S. patent no. 8,591,740 B2), involves injection of biocide into ballast seawater before it reaches the large surface fi lter intakes to reduce the growth of marine organisms that can clog the fi lters.

The technology is already incorporated in the Siemens

SeaCURE Ballast Water Management System that uses a combination of physical separation and a pro- prietary, on-demand treatment with biocides, produced in-situ from seawater, without the addition of chemi- cals. The SeaCURE system is based on more than 30 years experience on over 2,500 shipboard installations of Siemens’ well-known Chloropac biofouling control system.

The SeaCURE system employs fi lters to remove or break larger organisms using a 40-micron weave-wire screen and provides reliable, non-stop operation at high sediment loads while minimizing backwash fl ow.

The biofouling control provided to the fi lter assures

SeaCURE’s reliable function and minimizes main- tenance requirements of the system. The SeaCURE system can be used not only for treating ballast water, but also for treating onboard cooling water circuits.

The SeaCURE system is designed to comply with

IMO Convention D-2 regulations for ballast water management and received IMO fi nal approval in 2012.

SeaCURE is available in skid-mounted, containerized or as modular components depending on customer requirements for installation in newbuilds and existing ships. It is particularly well-suited for retrofi t installa- tions because biocide generation takes place in a small side stream taken off the ballast water main, minimiz- ing footprint and maximizing available space.

New BWM Regs Cometh Are you ready?

MR #2 (42-49).indd 46 2/4/2014 4:42:44 PM

45

45

47

47