Page 36: of Maritime Reporter Magazine (April 2014)

Offshore Edition

Read this page in Pdf, Flash or Html5 edition of April 2014 Maritime Reporter Magazine

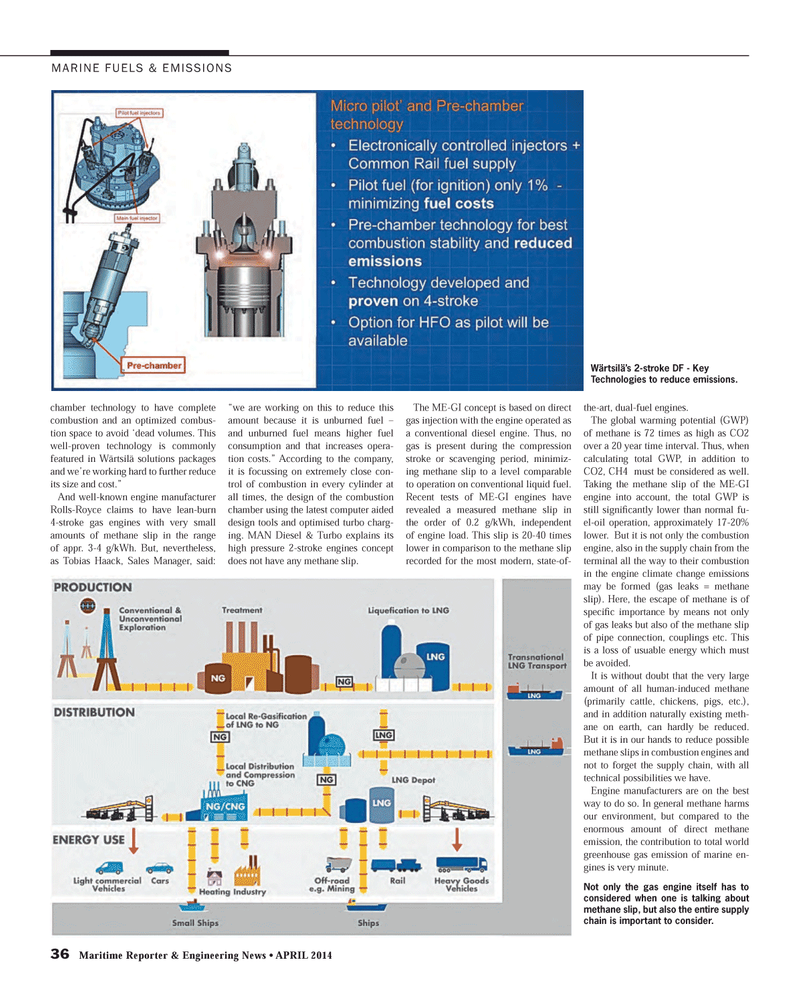

36 Maritime Reporter & Engineering News ? APRIL 2014 chamber technology to have complete combustion and an optimized combus-tion space to avoid ?dead volumes. This well-proven technology is commonly featured in Wärtsilä solutions packages and we?re working hard to further reduce its size and cost.?And well-known engine manufacturer Rolls-Royce claims to have lean-burn 4-stroke gas engines with very small amounts of methane slip in the range of appr. 3-4 g/kWh. But, nevertheless, as Tobias Haack, Sales Manager, said: ?we are working on this to reduce this amount because it is unburned fuel ? and unburned fuel means higher fuel consumption and that increases opera-tion costs.? According to the company, it is focussing on extremely close con-trol of combustion in every cylinder at all times, the design of the combustion chamber using the latest computer aided design tools and optimised turbo charg- ing. MAN Diesel & Turbo explains its high pressure 2-stroke engines concept does not have any methane slip.The ME-GI concept is based on direct gas injection with the engine operated as a conventional diesel engine. Thus, no gas is present during the compression stroke or scavenging period, minimiz-ing methane slip to a level comparable to operation on conventional liquid fuel. Recent tests of ME-GI engines have revealed a measured methane slip in the order of 0.2 g/kWh, independent of engine load. This slip is 20-40 times lower in comparison to the methane slip recorded for the most modern, state-of-the-art, dual-fuel engines.The global warming potential (GWP) of methane is 72 times as high as CO2 over a 20 year time interval. Thus, when calculating total GWP, in addition to CO2, CH4 must be considered as well. Taking the methane slip of the ME-GI engine into account, the total GWP is still signiÞ cantly lower than normal fu- el-oil operation, approximately 17-20% lower. But it is not only the combustion engine, also in the supply chain from the terminal all the way to their combustion in the engine climate change emissions may be formed (gas leaks = methane slip). Here, the escape of methane is of speciÞ c importance by means not only of gas leaks but also of the methane slip of pipe connection, couplings etc. This is a loss of usuable energy which must be avoided.It is without doubt that the very large amount of all human-induced methane (primarily cattle, chickens, pigs, etc.), and in addition naturally existing meth-ane on earth, can hardly be reduced. But it is in our hands to reduce possible methane slips in combustion engines and not to forget the supply chain, with all technical possibilities we have. Engine manufacturers are on the best way to do so. In general methane harms our environment, but compared to the enormous amount of direct methane emission, the contribution to total world greenhouse gas emission of marine en-gines is very minute. MARINE FUELS & EMISSIONSNot only the gas engine itself has to considered when one is talking about methane slip, but also the entire supply chain is important to consider. Wärtsilä?s 2-stroke DF - Key Technologies to reduce emissions. MR #4 (34-41).indd 36MR #4 (34-41).indd 364/4/2014 11:09:20 AM4/4/2014 11:09:20 AM

35

35

37

37