Page 20: of Maritime Reporter Magazine (July 2014)

Offshore Energy Structures & Systems

Read this page in Pdf, Flash or Html5 edition of July 2014 Maritime Reporter Magazine

20 Maritime Reporter & Engineering News • JULY 2014

PROPULSION

Turbocharger Modifi cati on

Cost Effective Solution for Fuel Saving and Emission Control

A turbocharger’s effi ciency sig- nifi cantly infl uences diesel engine performance. For ex- ample, a turbocharger (TC) effi ciency increase of one percent results in the following improvements, under constant engine power: • Supercharged air pressure increases 1% - 2% • Fuel consumption decreased 0.4% - 0.6% • NOx emission decreased 5% - 8% • Exhaust gas temp. down 2% - 4%

Operational turbocharger maximum effi ciency is achieved by the accurate coordination of turbocharger and diesel cylinders characteristics during the de- sign and the engine’s test-bed trial stage.

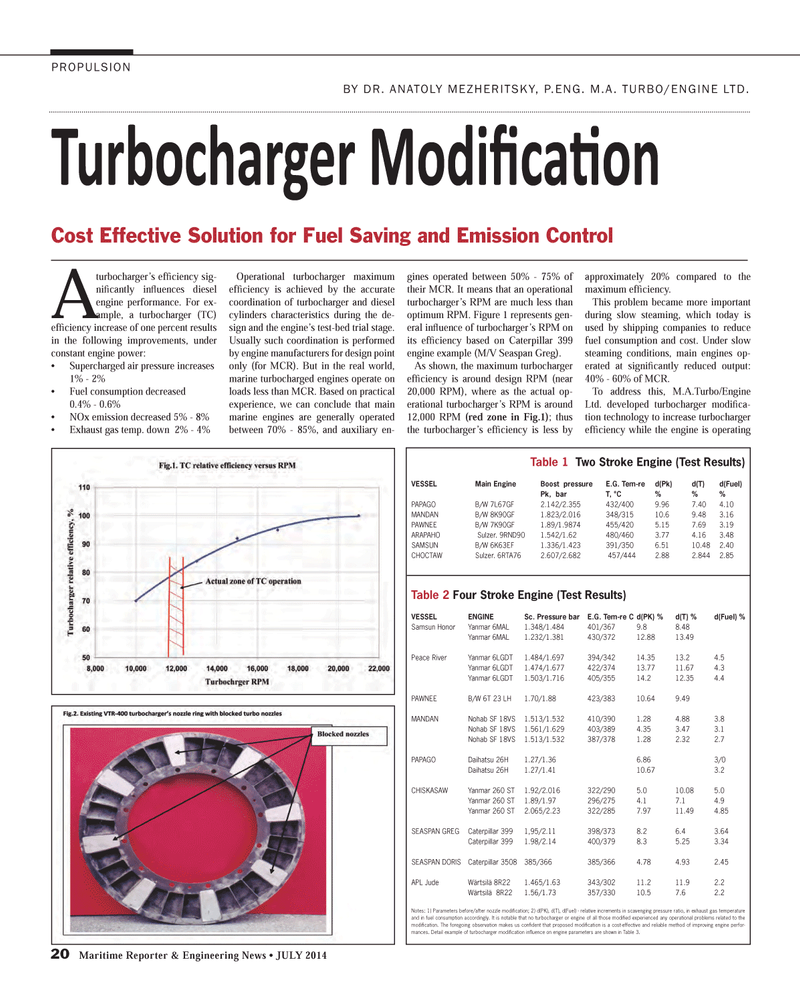

Usually such coordination is performed by engine manufacturers for design point only (for MCR). But in the real world, marine turbocharged engines operate on loads less than MCR. Based on practical experience, we can conclude that main marine engines are generally operated between 70% - 85%, and auxiliary en- gines operated between 50% - 75% of their MCR. It means that an operational turbocharger’s RPM are much less than optimum RPM. Figure 1 represents gen- eral infl uence of turbocharger’s RPM on its effi ciency based on Caterpillar 399 engine example (M/V Seaspan Greg).

As shown, the maximum turbocharger effi ciency is around design RPM (near 20,000 RPM), where as the actual op- erational turbocharger’s RPM is around 12,000 RPM (red zone in Fig.1); thus the turbocharger’s effi ciency is less by approximately 20% compared to the maximum effi ciency.

This problem became more important during slow steaming, which today is used by shipping companies to reduce fuel consumption and cost. Under slow steaming conditions, main engines op- erated at signifi cantly reduced output: 40% - 60% of MCR.

To address this, M.A.Turbo/Engine

Ltd. developed turbocharger modifi ca- tion technology to increase turbocharger effi ciency while the engine is operating

Table 1 Two Stroke Engine (Test Results)

VESSEL Main Engine Boost pressure E.G. Tem-re d(Pk) d(T) d(Fuel) Pk, bar T, °C % % %

PAPAGO B/W 7L67GF 2.142/2.355 432/400 9.96 7.40 4.10

MANDAN B/W 8K90GF 1.823/2.016 348/315 10.6 9.48 3.16

PAWNEE B/W 7K90GF 1.89/1.9874 455/420 5.15 7.69 3.19

ARAPAHO Sulzer. 9RND90 1.542/1.62 480/460 3.77 4.16 3.48

SAMSUN B/W 6K63EF 1.336/1.423 391/350 6.51 10.48 2.40

CHOCTAW Sulzer. 6RTA76 2.607/2.682 457/444 2.88 2.844 2.85

Table 2 Four Stroke Engine (Test Results)

VESSEL ENGINE Sc. Pressure bar E.G. Tem-re C d(PK) % d(T) % d(Fuel) %

Samsun Honor Yanmar 6MAL 1.348/1.484 401/367 9.8 8.48 Yanmar 6MAL 1.232/1.381 430/372 12.88 13.49

Peace River Yanmar 6LGDT 1.484/1.697 394/342 14.35 13.2 4.5 Yanmar 6LGDT 1.474/1.677 422/374 13.77 11.67 4.3 Yanmar 6LGDT 1.503/1.716 405/355 14.2 12.35 4.4

PAWNEE B/W 6T 23 LH 1.70/1.88 423/383 10.64 9.49

MANDAN Nohab SF 18VS 1.513/1.532 410/390 1.28 4.88 3.8 Nohab SF 18VS 1.561/1.629 403/389 4.35 3.47 3.1 Nohab SF 18VS 1.513/1.532 387/378 1.28 2.32 2.7

PAPAGO Daihatsu 26H 1.27/1.36 6.86 3/0 Daihatsu 26H 1.27/1.41 10.67 3.2

CHISKASAW Yanmar 260 ST 1.92/2.016 322/290 5.0 10.08 5.0 Yanmar 260 ST 1.89/1.97 296/275 4.1 7.1 4.9 Yanmar 260 ST 2.065/2.23 322/285 7.97 11.49 4.85

SEASPAN GREG Caterpillar 399 1,95/2.11 398/373 8.2 6.4 3.64 Caterpillar 399 1.98/2.14 400/379 8.3 5.25 3.34

SEASPAN DORIS Caterpillar 3508 385/366 385/366 4.78 4.93 2.45

APL Jude Wärtsilä 8R22 1.465/1.63 343/302 11.2 11.9 2.2 Wärtsilä 8R22 1.56/1.73 357/330 10.5 7.6 2.2

Notes: 1) Parameters before/after nozzle modifi cation; 2) d(PK), d(T), d(Fuel) - relative increments in scavenging pressure ratio, in exhaust gas temperature and in fuel consumption accordingly. It is notable that no turbocharger or engine of all those modifi ed experienced any operational problems related to the modifi cation. The foregoing observation makes us confi dent that proposed modifi cation is a cost-effective and reliable method of improving engine perfor- mances. Detail example of turbocharger modifi cation infl uence on engine parameters are shown in Table 3.

BY DR. ANATOLY MEZHERITSKY, P.ENG. M.A. TURBO/ENGINE LTD.

MR #7 (18-25).indd 20 6/30/2014 10:12:18 AM

19

19

21

21