Page 10: of Maritime Reporter Magazine (October 2014)

Marine Design Edition

Read this page in Pdf, Flash or Html5 edition of October 2014 Maritime Reporter Magazine

10 Maritime Reporter & Engineering News • OCTOBER 2014

NEWS

L ast month steel was cut on what is arguably the most signifi cant shipbuilding project to support

Arctic route operations. With a cer- emony to mark the fi rst cutting of steel, construction has begun on the fi rst of sixteen 300m long, 170,000 cu. m. Arc- tic LNG Carriers being built in South

Korea by DSME for operation on the

Northern Passage, with the fi rst sched- uled to come online in 2016 for regular transport between the Yamal LNG proj- ect based in the estuary of the Ob River and Asia.

The prototype vessel will be operated under a long-term time charter between

OAO Sovcomfl ot and JSC Yamal LNG.

The ships are custom designed “Dou- ble Acting” vessels powered by three 15MW Azipods for a total power of 45MW. “This is a real breakthrough in the Arctic commercial transporta- tion traffi c, as this is the fi rst project on a regular commercial traffi c basis,” said Mikko Niini, senior advisor today and for the past 10 years CEO of Aker

Arctic, in an interview earlier this year with Maritime Reporter & Engineering

News.

The Yamal LNG project is ice-bound nine months of the year and the project is to ensure production and marketing of the Russian Arctic’s natural gas re- serves. It is one of the largest industrial undertakings in the Arctic, and eventu- ally will involve the drilling of more than 200 wells and construction of the aforementioned 16 icebreaking tankers, making up three ‘LNG trains.’

While the fi nal costs of the ships have not been publicly released, professional estimates suggest that each ship will cost in the region of $300 million, or an approximate 50% premium versus the cost of a similarly sized LNG car- rier not built for Arctic operations. The main cost drivers for these ships are added steel and power, but several key ship systems must be winterized, add- ing to the cost and including: • Protection of deck equipment • Ballast tank heating • Insulation in housing • Pre-heating of the equipment

And they’re off …

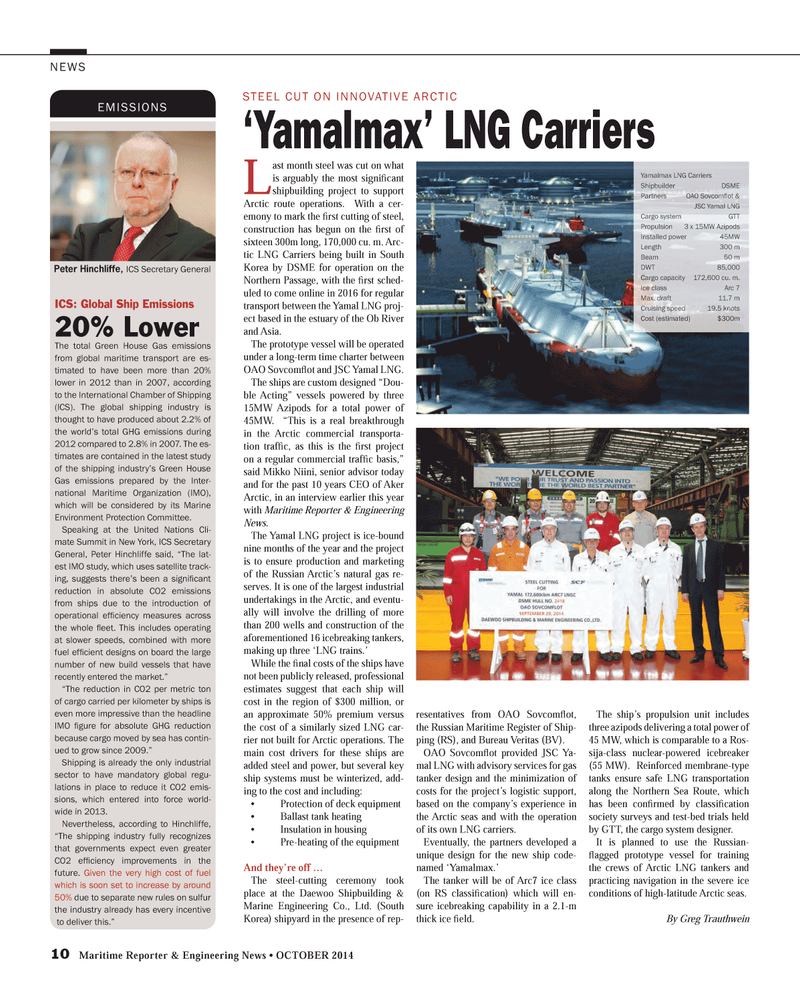

The steel-cutting ceremony took place at the Daewoo Shipbuilding &

Marine Engineering Co., Ltd. (South

Korea) shipyard in the presence of rep- resentatives from OAO Sovcomfl ot, the Russian Maritime Register of Ship- ping (RS), and Bureau Veritas (BV).

OAO Sovcomfl ot provided JSC Ya- mal LNG with advisory services for gas tanker design and the minimization of costs for the project’s logistic support, based on the company’s experience in the Arctic seas and with the operation of its own LNG carriers.

Eventually, the partners developed a unique design for the new ship code- named ‘Yamalmax.’

The tanker will be of Arc7 ice class (on RS classifi cation) which will en- sure icebreaking capability in a 2.1-m thick ice fi eld.

The ship’s propulsion unit includes three azipods delivering a total power of 45 MW, which is comparable to a Ros- sija-class nuclear-powered icebreaker (55 MW). Reinforced membrane-type tanks ensure safe LNG transportation along the Northern Sea Route, which has been confi rmed by classifi cation society surveys and test-bed trials held by GTT, the cargo system designer.

It is planned to use the Russian- fl agged prototype vessel for training the crews of Arctic LNG tankers and practicing navigation in the severe ice conditions of high-latitude Arctic seas.

By Greg Trauthwein ‘Yamalmax’ LNG Carriers

STEEL CUT ON INNOVATIVE ARCTIC

Yamalmmax axa LNGNGG CaaC rriers

Shihipbupb ilddlderer r DSMME

ParP tneeners s OAOO SSovcomfl ot o &&

JSC Yamall LNGLNL

CCargo systtem GTT

Pro lpulsion 33 xx 15MWAWW Azip dods

Installeded power 455MW

Length 300mm0 m

Beam 5m 50m0 m

DWT 85,00000

CarCaaraC gogo g capacia ty 172,62 00 00 cu. m.m

IceceIcce cclaasss Arc7c 7

Maxaxx d. d. drafraafa t 1tt 1.7 m

CruC uisiiis nng ngg sspep edd 19.9 5k5 kk5 nototn s

CosCo t ((estese imama dte ) $$3003 m

ICS: Global Ship Emissions 20% Lower

The total Green House Gas emissions from global maritime transport are es- timated to have been more than 20% lower in 2012 than in 2007, according to the International Chamber of Shipping (ICS). The global shipping industry is thought to have produced about 2.2% of the world’s total GHG emissions during 2012 compared to 2.8% in 2007. The es- timates are contained in the latest study of the shipping industry’s Green House

Gas emissions prepared by the Inter- national Maritime Organization (IMO), which will be considered by its Marine

Environment Protection Committee.

Speaking at the United Nations Cli- mate Summit in New York, ICS Secretary

General, Peter Hinchliffe said, “The lat- est IMO study, which uses satellite track- ing, suggests there’s been a signifi cant reduction in absolute CO2 emissions from ships due to the introduction of operational effi ciency measures across the whole fl eet. This includes operating at slower speeds, combined with more fuel effi cient designs on board the large number of new build vessels that have recently entered the market.” “The reduction in CO2 per metric ton of cargo carried per kilometer by ships is even more impressive than the headline

IMO fi gure for absolute GHG reduction because cargo moved by sea has contin- ued to grow since 2009.”

Shipping is already the only industrial sector to have mandatory global regu- lations in place to reduce it CO2 emis- sions, which entered into force world- wide in 2013.

Nevertheless, according to Hinchliffe, “The shipping industry fully recognizes that governments expect even greater

CO2 effi ciency improvements in the future. Given the very high cost of fuel which is soon set to increase by around 50% due to separate new rules on sulfur the industry already has every incentive to deliver this.”

EMISSIONS

Peter Hinchliffe, ICS Secretary General

MR #10 (10-17).indd 10 10/1/2014 9:26:40 AM

9

9

11

11