Page 14: of Maritime Reporter Magazine (July 2015)

Marine Communications Edition

Read this page in Pdf, Flash or Html5 edition of July 2015 Maritime Reporter Magazine

MARINE FUELS

Fuel Switching

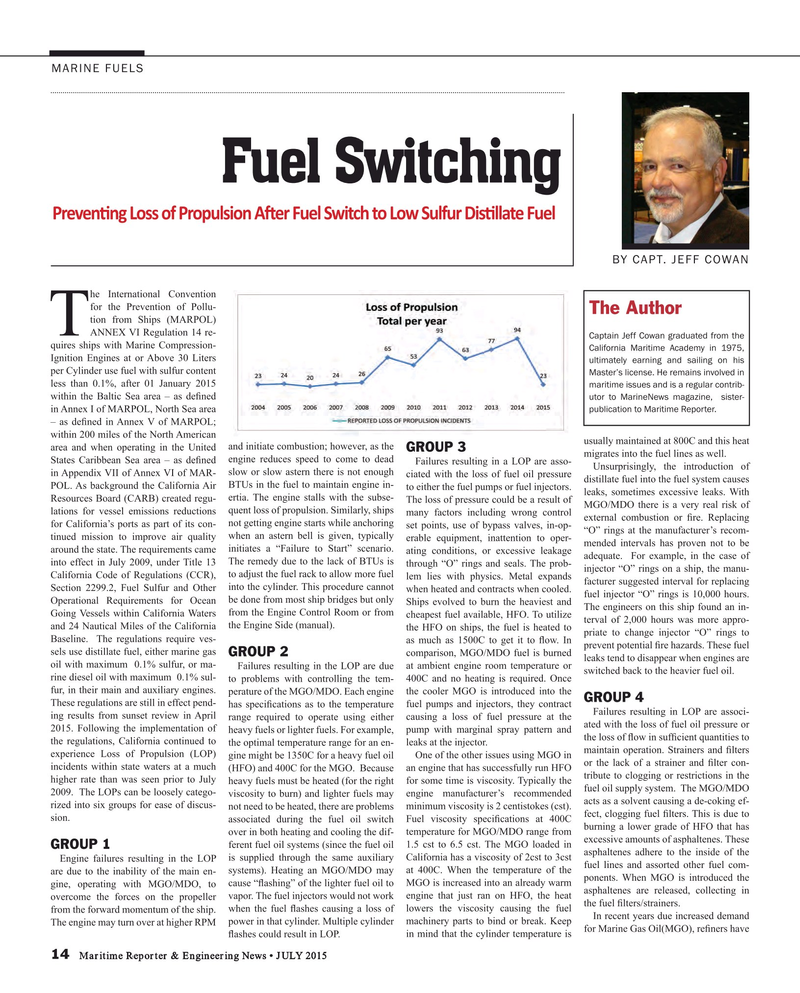

Prevent ng Loss of Propulsion Af er Fuel Switch to Low Sulfur Dist llate Fuel

BY CAPT. JEFF COWAN he International Convention for the Prevention of Pollu-

The Author tion from Ships (MARPOL)

TANNEX VI Regulation 14 re-

Captain Jeff Cowan graduated from the quires ships with Marine Compression-

California Maritime Academy in 1975,

Ignition Engines at or Above 30 Liters ultimately earning and sailing on his per Cylinder use fuel with sulfur content

Master’s license. He remains involved in less than 0.1%, after 01 January 2015 maritime issues and is a regular contrib- within the Baltic Sea area – as de? ned utor to MarineNews magazine, sister- publication to Maritime Reporter.

in Annex I of MARPOL, North Sea area – as de? ned in Annex V of MARPOL; within 200 miles of the North American usually maintained at 800C and this heat area and when operating in the United and initiate combustion; however, as the

GROUP 3 migrates into the fuel lines as well.

States Caribbean Sea area – as de? ned engine reduces speed to come to dead

Failures resulting in a LOP are asso-

Unsurprisingly, the introduction of slow or slow astern there is not enough ciated with the loss of fuel oil pressure distillate fuel into the fuel system causes in Appendix VII of Annex VI of MAR-

POL. As background the California Air BTUs in the fuel to maintain engine in- to either the fuel pumps or fuel injectors. leaks, sometimes excessive leaks. With ertia. The engine stalls with the subse-

Resources Board (CARB) created regu-

The loss of pressure could be a result of

MGO/MDO there is a very real risk of lations for vessel emissions reductions quent loss of propulsion. Similarly, ships many factors including wrong control external combustion or ? re. Replacing not getting engine starts while anchoring set points, use of bypass valves, in-op- for California’s ports as part of its con- “O” rings at the manufacturer’s recom- tinued mission to improve air quality when an astern bell is given, typically erable equipment, inattention to oper- mended intervals has proven not to be around the state. The requirements came initiates a “Failure to Start” scenario. ating conditions, or excessive leakage adequate. For example, in the case of into effect in July 2009, under Title 13 The remedy due to the lack of BTUs is through “O” rings and seals. The prob- injector “O” rings on a ship, the manu-

California Code of Regulations (CCR), to adjust the fuel rack to allow more fuel lem lies with physics. Metal expands facturer suggested interval for replacing

Section 2299.2, Fuel Sulfur and Other into the cylinder. This procedure cannot when heated and contracts when cooled. fuel injector “O” rings is 10,000 hours.

Operational Requirements for Ocean be done from most ship bridges but only Ships evolved to burn the heaviest and The engineers on this ship found an in-

Going Vessels within California Waters from the Engine Control Room or from cheapest fuel available, HFO. To utilize terval of 2,000 hours was more appro- and 24 Nautical Miles of the California the Engine Side (manual). the HFO on ships, the fuel is heated to priate to change injector “O” rings to

Baseline. The regulations require ves- as much as 1500C to get it to ? ow. In prevent potential ? re hazards. These fuel sels use distillate fuel, either marine gas comparison, MGO/MDO fuel is burned leaks tend to disappear when engines are

GROUP 2 oil with maximum 0.1% sulfur, or ma-

Failures resulting in the LOP are due at ambient engine room temperature or switched back to the heavier fuel oil.

rine diesel oil with maximum 0.1% sul- to problems with controlling the tem- 400C and no heating is required. Once fur, in their main and auxiliary engines. perature of the MGO/MDO. Each engine the cooler MGO is introduced into the

GROUP 4

These regulations are still in effect pend- has speci? cations as to the temperature fuel pumps and injectors, they contract

Failures resulting in LOP are associ- ing results from sunset review in April range required to operate using either causing a loss of fuel pressure at the 2015. Following the implementation of heavy fuels or lighter fuels. For example, pump with marginal spray pattern and ated with the loss of fuel oil pressure or the loss of ? ow in suf? cient quantities to the regulations, California continued to the optimal temperature range for an en- leaks at the injector.

maintain operation. Strainers and ? lters experience Loss of Propulsion (LOP) gine might be 1350C for a heavy fuel oil One of the other issues using MGO in or the lack of a strainer and ? lter con- incidents within state waters at a much (HFO) and 400C for the MGO. Because an engine that has successfully run HFO tribute to clogging or restrictions in the higher rate than was seen prior to July heavy fuels must be heated (for the right for some time is viscosity. Typically the 2009. The LOPs can be loosely catego- viscosity to burn) and lighter fuels may engine manufacturer’s recommended fuel oil supply system. The MGO/MDO acts as a solvent causing a de-coking ef- rized into six groups for ease of discus- not need to be heated, there are problems minimum viscosity is 2 centistokes (cst). sion. associated during the fuel oil switch Fuel viscosity speci? cations at 400C fect, clogging fuel ? lters. This is due to burning a lower grade of HFO that has over in both heating and cooling the dif- temperature for MGO/MDO range from ferent fuel oil systems (since the fuel oil 1.5 cst to 6.5 cst. The MGO loaded in excessive amounts of asphaltenes. These

GROUP 1 asphaltenes adhere to the inside of the

Engine failures resulting in the LOP is supplied through the same auxiliary California has a viscosity of 2cst to 3cst systems). Heating an MGO/MDO may at 400C. When the temperature of the fuel lines and assorted other fuel com- are due to the inability of the main en- ponents. When MGO is introduced the gine, operating with MGO/MDO, to cause “? ashing” of the lighter fuel oil to MGO is increased into an already warm overcome the forces on the propeller vapor. The fuel injectors would not work engine that just ran on HFO, the heat asphaltenes are released, collecting in from the forward momentum of the ship. when the fuel ? ashes causing a loss of lowers the viscosity causing the fuel the fuel ? lters/strainers.

In recent years due increased demand

The engine may turn over at higher RPM power in that cylinder. Multiple cylinder machinery parts to bind or break. Keep for Marine Gas Oil(MGO), re? ners have ? ashes could result in LOP. in mind that the cylinder temperature is 14 Maritime Reporter & Engineering News • JULY 2015

MR #7 (10-17).indd 14 MR #7 (10-17).indd 14 7/6/2015 9:31:55 AM7/6/2015 9:31:55 AM

13

13

15

15