Page 60: of Maritime Reporter Magazine (October 2015)

Marine Design Annual

Read this page in Pdf, Flash or Html5 edition of October 2015 Maritime Reporter Magazine

SOFTWARE SOLUTIONS

BMT Fluid Mechanics to

Validate FLNG Design he emergence of the ? oating clean-energy alternative to traditional sociated metocean conditions, including pact on marine environment; possible lique? ed natural gas (FLNG) fossil fuels has resulted in unprecedented wave motions, can create signi? cant likelihood and consequence of ? re and concept has seen an unprec- innovation in the global offshore LNG challenges. explosion; security and evacuation and

Tedented focus on development industry. In the last 10 years alone, pro- Advantages of FLNG units include a in-service maintenance. The effective activity and has reinforced the commer- ducers have made rapid ef? ciency im- reduced use of materials, land and sea- management of all of these risks should cial interest in these facilities. However, provements within the value chain, ? rst bed and therefore, cost and a reduced involve a quantitative assessment to help as the industry strives to make the con- through the use of re-gasi? cation vessels impact on coastal habitats by avoiding optimize the design, incorporate miti- cept a reality, in addition to the already and then ? oating storage and re-gasi? ca- pipelines, dredging activities and jetty gation measures and devise hazard and formidable risks present in conventional tion units (FSRU). FLNG represents the construction. In addition, the ? exibil- management strategies. projects, a plethora of distinctive risks latest development in this fast-moving ity of the concept allows for a gas ? eld The greatest opportunities to reduce associated with FLNG have now been industry sector. to be exploited and then theoretically, it risks are during the initial hazard assess- added to the mix, with little industry ex- Floating above an offshore natural gas can be simply moved to another loca- ment stage within the conceptual design perience to learn from. Simply adapting ? eld, the FLNG facility will theoreti- tion, rather than having to be decom- phase whereby an inherently safer de- risk and safety concepts of land-based cally produce, liquefy, store and transfer missioned. Owners must anticipate fu- sign can be achieved. Once a more de-

LNG developments is not the solution, LNG and potentially lique? ed petroleum ture requirements and deliver long-term tailed design has been agreed, there may believes Suba Sivandran, Head of Oil gas (LPG) and condensate at sea before performance, which in turn, places even be limited scope to apply hazard avoid- and Gas at BMT Fluid Mechanics, a sub- carriers ship the product direct to mar- greater pressure on ensuring optimum ance methods. sidiary of BMT Group. Suba highlights ket. Although this approach has its ben- design and asset integrity management The offshore oil and gas industry is the unique safety concerns which need e? ts, it also presents its own challenges. of the facility. increasingly moving towards a more to be considered and provides insight When considering the design and con- As the number of proposed FLNG fa- proactive approach to risk mitigation into the bene? ts of using Computational struction of the FLNG facility, every ele- cilities increase to meet the demand for and away from a reactive approach. A

Fluid Dynamics (CFD) to complement ment of a conventional land-based LNG transportation of gas reserves stranded in formal safety assessment or safety case physical modelling through Wind Tun- facility needs to ? t into an area a fraction remote offshore locations such as South approach is a structured way of handling nel Testing and ensure oil and gas opera- of the size, while maintaining appropri- East Asia and Africa, it is essential that risks. Through an initial hazard assess- tors have con? dence that the design is ? t ate levels of safety and giving increased the safety risks are fully understood ment, hazards are identi? ed and mea- for purpose in all operating conditions. ? exibility to LNG production. Further- within the concept design phase. These sured qualitatively. Certain hazards that

Growing demand for natural gas as a more, the offshore environment and as- risks relate to: metocean conditions; im- are deemed to have the potential to cause a major accident event (MAE) are then taken forward to the consequence as- sessment stage where these hazards are

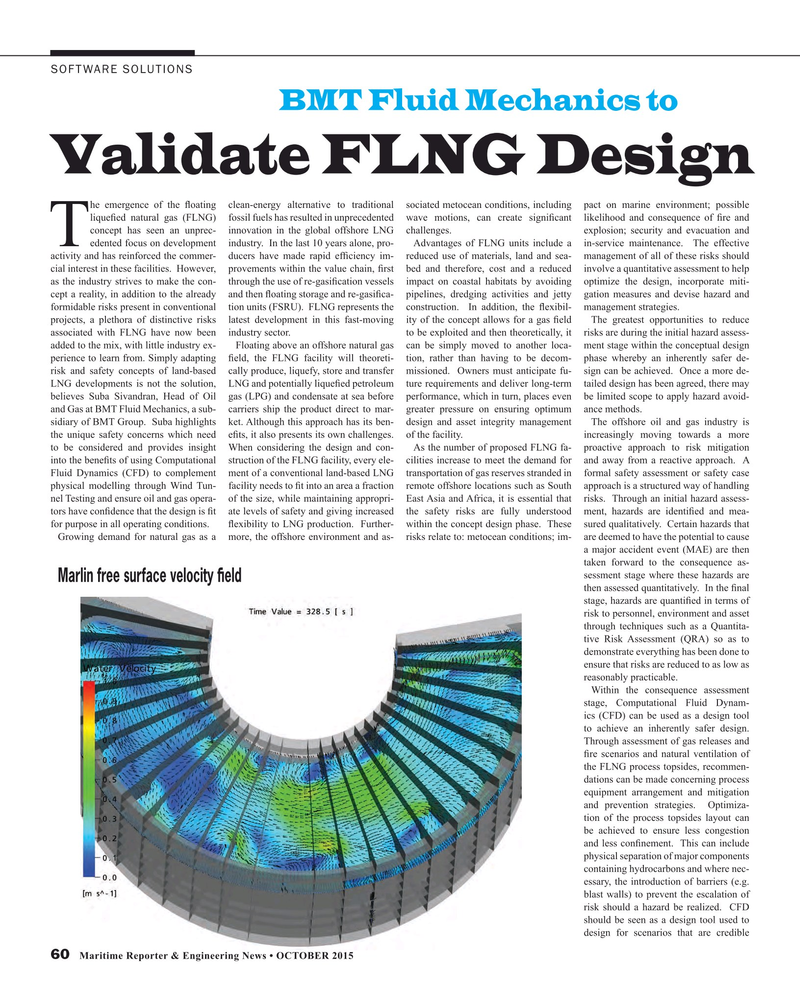

Marlin free surface velocity ? eld then assessed quantitatively. In the ? nal stage, hazards are quanti? ed in terms of risk to personnel, environment and asset through techniques such as a Quantita- tive Risk Assessment (QRA) so as to demonstrate everything has been done to ensure that risks are reduced to as low as reasonably practicable.

Within the consequence assessment stage, Computational Fluid Dynam- ics (CFD) can be used as a design tool to achieve an inherently safer design.

Through assessment of gas releases and ? re scenarios and natural ventilation of the FLNG process topsides, recommen- dations can be made concerning process equipment arrangement and mitigation and prevention strategies. Optimiza- tion of the process topsides layout can be achieved to ensure less congestion and less con? nement. This can include physical separation of major components containing hydrocarbons and where nec- essary, the introduction of barriers (e.g. blast walls) to prevent the escalation of risk should a hazard be realized. CFD should be seen as a design tool used to design for scenarios that are credible 60 Maritime Reporter & Engineering News • OCTOBER 2015

MR #10 (58-65).indd 60 10/2/2015 11:46:52 AM

59

59

61

61