Page 40: of Maritime Reporter Magazine (December 2015)

Great Ships of 2015

Read this page in Pdf, Flash or Html5 edition of December 2015 Maritime Reporter Magazine

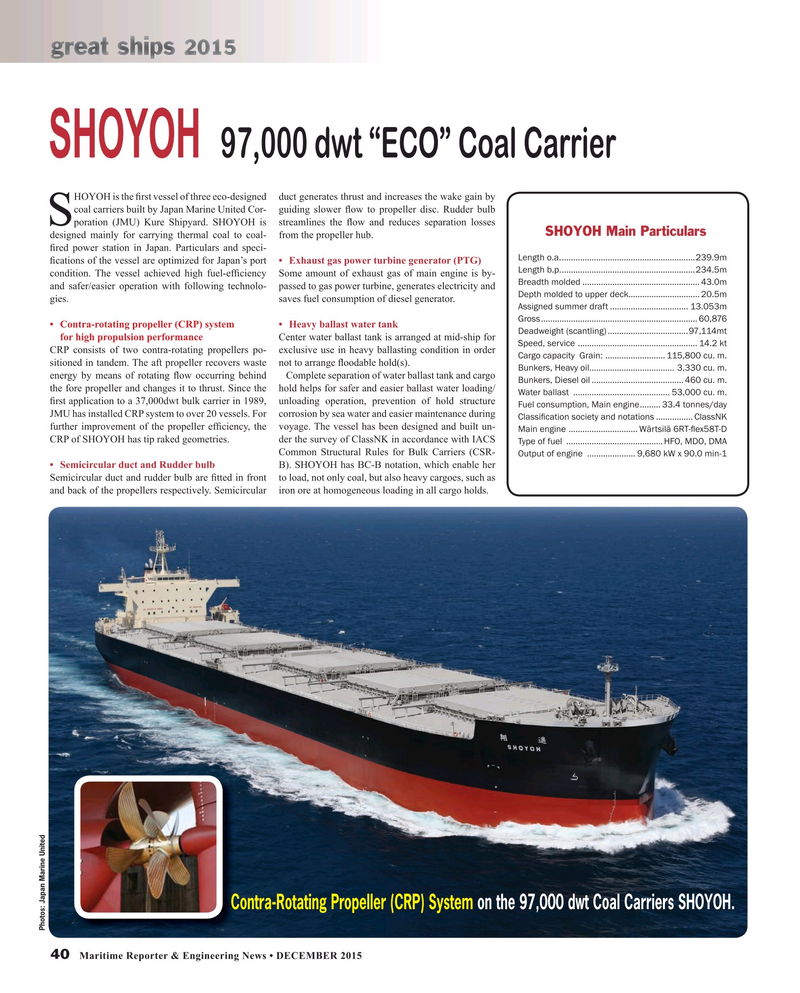

SHOYOH 97,000 dwt “ECO” Coal Carrier

HOYOH is the ? rst vessel of three eco-designed duct generates thrust and increases the wake gain by coal carriers built by Japan Marine United Cor- guiding slower ? ow to propeller disc. Rudder bulb

Sporation (JMU) Kure Shipyard. SHOYOH is streamlines the ? ow and reduces separation losses

SHOYOH Main Particulars designed mainly for carrying thermal coal to coal- from the propeller hub.

? red power station in Japan. Particulars and speci-

Length o.a. ..........................................................239.9m ? cations of the vessel are optimized for Japan’s port • Exhaust gas power turbine generator (PTG)

Length b.p. ..........................................................234.5m condition. The vessel achieved high fuel-ef? ciency Some amount of exhaust gas of main engine is by-

Breadth molded ...................................................43.0m and safer/easier operation with following technolo- passed to gas power turbine, generates electricity and

Depth molded to upper deck...............................20.5m gies. saves fuel consumption of diesel generator.

Assigned summer draft ..................................13.053m

Gross ....................................................................60,876 • Contra-rotating propeller (CRP) system • Heavy ballast water tank

Deadweight (scantling) ...................................97,114mt for high propulsion performance Center water ballast tank is arranged at mid-ship for

Speed, service ....................................................14.2 kt

CRP consists of two contra-rotating propellers po- exclusive use in heavy ballasting condition in order

Cargo capacity Grain: ..........................115,800 cu. m.

sitioned in tandem. The aft propeller recovers waste not to arrange ? oodable hold(s).

Bunkers, Heavy oil..................................... 3,330 cu. m.

energy by means of rotating ? ow occurring behind Complete separation of water ballast tank and cargo

Bunkers, Diesel oil ........................................460 cu. m.

the fore propeller and changes it to thrust. Since the hold helps for safer and easier ballast water loading/

Water ballast ..........................................53,000 cu. m.

? rst application to a 37,000dwt bulk carrier in 1989, unloading operation, prevention of hold structure

Fuel consumption, Main engine .........33.4 tonnes/day

JMU has installed CRP system to over 20 vessels. For corrosion by sea water and easier maintenance during

Classi? cation society and notations ................ClassNK further improvement of the propeller ef? ciency, the voyage. The vessel has been designed and built un-

Main engine ..............................Wärtsilä 6RT-? ex58T-D

CRP of SHOYOH has tip raked geometries. der the survey of ClassNK in accordance with IACS

Type of fuel ..........................................HFO, MDO, DMA

Common Structural Rules for Bulk Carriers (CSR-

Output of engine .....................9,680 kW x 90.0 min-1 • Semicircular duct and Rudder bulb B). SHOYOH has BC-B notation, which enable her

Semicircular duct and rudder bulb are ? tted in front to load, not only coal, but also heavy cargoes, such as and back of the propellers respectively. Semicircular iron ore at homogeneous loading in all cargo holds.

Contra-Rotating Propeller (CRP) System on the 97,000 dwt Coal Carriers SHOYOH.

Photos: Japan Marine United 40 Maritime Reporter & Engineering News • DECEMBER 2015

MR #12 (34-40).indd 40 12/4/2015 1:01:28 PM

39

39

41

41