Page 16: of Maritime Reporter Magazine (September 2016)

Maritime & Ship Security

Read this page in Pdf, Flash or Html5 edition of September 2016 Maritime Reporter Magazine

MARINE FUELS

Fuels of the Future

Chosing your ? eet’s future fuel wisely

WAJDI ABDMESSIH he imposition of a global 0.5% rameters in relation to biofuel that could

CertificateOfAnalysis sulfur cap may be less than four be problematic for a marine diesel en-

Summary:

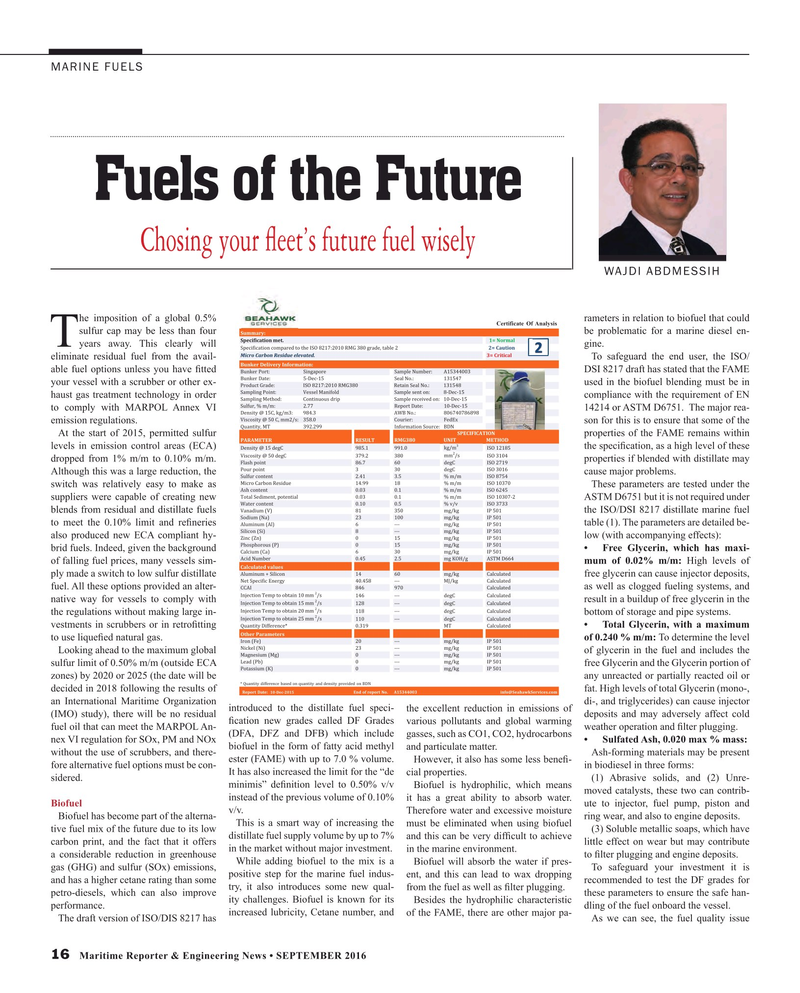

Specification met. 1= Normal

Tyears away. This clearly will gine.

Specification compared to the ISO 8217:2010 RMG 380 grade, table 2 2= Caution

Micro Carbon Residue elevated. 3= Critical eliminate residual fuel from the avail- To safeguard the end user, the ISO/

Bunker Delivery Information: able fuel options unless you have ? tted DSI 8217 draft has stated that the FAME

Bunker Port: Singapore Sample Number: A15344003

Bunker Date: 5-Dec-15 Seal No.: 131547 your vessel with a scrubber or other ex- used in the biofuel blending must be in

Product Grade: ISO 8217:2010 RMG380 Retain Seal No.: 131548

Sampling Point: Vessel Manifold Sample sent on: 8-Dec-15 haust gas treatment technology in order compliance with the requirement of EN

Sampling Method: Continuous drip Sample received on: 10-Dec-15

Sulfur, % m/m: 2.77 Report Date: 10-Dec-15 to comply with MARPOL Annex VI 14214 or ASTM D6751. The major rea-

Density @ 15C, kg/m3: 984.3 AWB No.: 806740786898

Viscosity @ 50 C, mm2/s: 358.0 Courier: FedEx emission regulations. son for this is to ensure that some of the

Quantity, MT 392.299 Information Source: BDN

SPECIFICATION

At the start of 2015, permitted sulfur properties of the FAME remains within

RESULT PARAMETER RMG380 UNIT METHOD 3 levels in emission control areas (ECA) the speci? cation, as a high level of these 985.1 Density @ 15 degC 991.0 kg/m ISO 12185 2 mm /s

Viscosity @ 50 degC 379.2 380 ISO 3104 dropped from 1% m/m to 0.10% m/m. properties if blended with distillate may

Flash point 86.7 60 degC ISO 2719

Pour point 3 30 degC ISO 3016

Although this was a large reduction, the cause major problems.

Sulfur content 2.41 3.5 % m/m ISO 8754

Micro Carbon Residue 14.99 18 % m/m ISO 10370 switch was relatively easy to make as These parameters are tested under the

Ash content 0.03 0.1 % m/m ISO 6245

Total Sediment, potential 0.03 0.1 % m/m ISO 10307-2 suppliers were capable of creating new ASTM D6751 but it is not required under

Water content 0.10 0.5 % v/v ISO 3733

Vanadium (V) 81 350 mg/kg IP 501 blends from residual and distillate fuels the ISO/DSI 8217 distillate marine fuel

Sodium (Na) 23 100 mg/kg IP 501 to meet the 0.10% limit and re? neries table (1). The parameters are detailed be-

Aluminum (Al) 6 --- mg/kg IP 501

Silicon (Si) 8 --- mg/kg IP 501 also produced new ECA compliant hy- low (with accompanying effects):

Zinc (Zn) 0 15 mg/kg IP 501

Phosphorous (P) 0 15 mg/kg IP 501 brid fuels. Indeed, given the background • Free Glycerin, which has maxi-

Calcium (Ca) 6 30 mg/kg IP 501

Acid Number 0.45 2.5 mg KOH/g ASTM D664 of falling fuel prices, many vessels sim- mum of 0.02% m/m: High levels of

Calculated values

Aluminum + Silicon 14 60 mg/kg Calculated ply made a switch to low sulfur distillate free glycerin can cause injector deposits,

Net Specific Energy 40.458 --- MJ/kg Calculated fuel. All these options provided an alter- as well as clogged fueling systems, and

CCAI 846 970 Calculated 2

Injection Temp to obtain 10 mm /s 146 --- degC Calculated native way for vessels to comply with result in a buildup of free glycerin in the 2

Injection Temp to obtain 15 mm /s 128 --- degC Calculated 2

Injection Temp to obtain 20 mm /s 118 --- degC Calculated the regulations without making large in- bottom of storage and pipe systems.

2

Injection Temp to obtain 25 mm /s 110 --- degC Calculated

Quantity Difference* 0.319 MT Calculated vestments in scrubbers or in retro? tting • Total Glycerin, with a maximum

Other Parameters to use lique? ed natural gas. of 0.240 % m/m: To determine the level

Iron (Fe) 20 --- mg/kg IP 501

Nickel (Ni) 23 --- mg/kg IP 501

Looking ahead to the maximum global of glycerin in the fuel and includes the

Magnesium (Mg) 0 --- mg/kg IP 501

Lead (Pb) 0 --- mg/kg IP 501 sulfur limit of 0.50% m/m (outside ECA free Glycerin and the Glycerin portion of

Potassium (K) 0 --- mg/kg IP 501 zones) by 2020 or 2025 (the date will be any unreacted or partially reacted oil or * Quantity difference based on quantity and density provided on BDN decided in 2018 following the results of fat. High levels of total Glycerin (mono-,

Report Date: End of report No. A15344003 [email protected] 10-Dec-2015 an International Maritime Organization di-, and triglycerides) can cause injector ddh introduced to the distillate fuel speci- (IMO) study), there will be no residual the excellent reduction in emissions of deposits and may adversely affect cold fuel oil that can meet the MARPOL An- ? cation new grades called DF Grades various pollutants and global warming weather operation and ?lter plugging. (DFA, DFZ and DFB) which include gasses, such as CO1, CO2, hydrocarbons nex VI regulation for SOx, PM and NOx • Sulfated Ash, 0.020 max % mass: biofuel in the form of fatty acid methyl and particulate matter. without the use of scrubbers, and there- Ash-forming materials may be present ester (FAME) with up to 7.0 % volume. However, it also has some less bene? - fore alternative fuel options must be con- in biodiesel in three forms:

It has also increased the limit for the “de cial properties.

sidered. (1) Abrasive solids, and (2) Unre- minimis” de? nition level to 0.50% v/v Biofuel is hydrophilic, which means instead of the previous volume of 0.10% it has a great ability to absorb water. moved catalysts, these two can contrib-

Biofuel ute to injector, fuel pump, piston and v/v. Therefore water and excessive moisture

Biofuel has become part of the alterna- ring wear, and also to engine deposits.

This is a smart way of increasing the must be eliminated when using biofuel tive fuel mix of the future due to its low (3) Soluble metallic soaps, which have carbon print, and the fact that it offers distillate fuel supply volume by up to 7% and this can be very dif? cult to achieve little effect on wear but may contribute a considerable reduction in greenhouse in the market without major investment. in the marine environment.

to ?lter plugging and engine deposits.

While adding biofuel to the mix is a Biofuel will absorb the water if pres- gas (GHG) and sulfur (SOx) emissions, To safeguard your investment it is positive step for the marine fuel indus- and has a higher cetane rating than some ent, and this can lead to wax dropping recommended to test the DF grades for these parameters to ensure the safe han- petro-diesels, which can also improve try, it also introduces some new qual- from the fuel as well as ? lter plugging.

ity challenges. Biofuel is known for its performance. Besides the hydrophilic characteristic dling of the fuel onboard the vessel.

increased lubricity, Cetane number, and of the FAME, there are other major pa-

The draft version of ISO/DIS 8217 has As we can see, the fuel quality issue 16 Maritime Reporter & Engineering News • SEPTEMBER 2016

MR #9 (10-17).indd 16 9/2/2016 10:12:54 AM

15

15

17

17