Page 20: of Maritime Reporter Magazine (September 2016)

Maritime & Ship Security

Read this page in Pdf, Flash or Html5 edition of September 2016 Maritime Reporter Magazine

SHIPYARD FOCUS to dry dock no. 2 and lifted on to the ves- blasting was performed using The Flow way for Cabins. GBSL +GF+ Quali? ed Coating to ? at bottom, vertical sides, sel. Once ? tted, the unit was handed over UHP Blasting Equipment. there after, Installers assisted owner technicians on boot top) three Coats to top sides. Two to the engaged out? tting contractor for two coats of Anti-Corrosive (AC) and the installation of the pipework. coats of Anti-Fouling (AF) and two coats completion of the suite’s interiors. two coats of Silicone (FRC - Foul Re- o Considerable (11,888 sq. m.) hull of Anti-Corrosive on bulbous bow and o Considerable (10,216 sq. m.) hull lease Coating) to Flat bottom; two coats blasting was performed using The Flow bow thruster area using the airless spray blasting was performed using The Flow of AC and two coats of FRC to Vertical UHP Blasting Equipment. there after, unit. Paint Manufactures: Nippon on ? at

UHP Blasting Equipment. Afterwards, Sides; 3 coats of AC to topsides were four Coats (two Coats of Anti-Corrosive bottom, vertical sides and boot top and two coats of Anti-Corrosive (AC) and applied using the airless spray unit, In- - AC and two coats of Self Polishing International on top sides two coats of Silicone (FRC - Foul Re- ternational Marine Coatings Coating - SPC) were applied using the o A riding squad was provided: Rid- lease Coating) to Flat bottom; two coats o Approximately 37,946kg (37 airless spray unit, with Hempel Paint ing squad (6 persons) sent 1 week in of AC and two coats of FRC to Vertical tonnes) of tank top and steel work was advance to Grand Cayman. It included

Sides; three coats of AC to topsides were replaced. Norwegian Dawn two certi? ed welders, three platers and applied using the airless spray unit using o 27 days of dry dock on ? oating dry the Cruise Service Manager, Craig Stark.

Hempel paint. Carnival Sunshine dock no. 2 To install steel frame work on Mooring o 11 day dry dock on ? oating dry o Considerable (13,981 sq. m.) hull Deck prior to the vessel’s arrival in prep-

Prinsendam dock no. 2 blasting was performed using The Flow aration for azipod removal for azipod o 12 day Dry Dock on Floating Dry o Hot and Cold PW piping was re- UHP Blasting Equipment. there after, maintenance. Azipod repair Included

Dock No. 3 placed, Georg Fischer pipework in- four Coats (two coats of Anti-Corrosive Port and starboard slewing bearings that o Considerable (10,216 sq. m.) hull stalled on Deck 2 throughout passage- (AC) and two coats of Self Polishing were replaced.

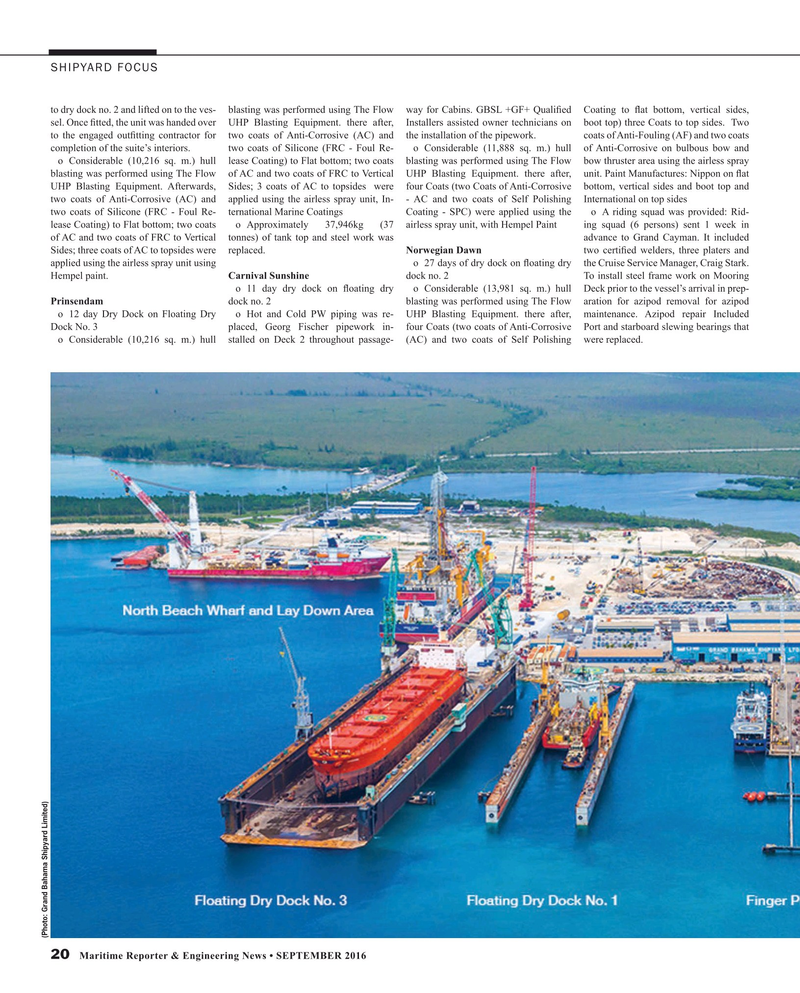

(Photo: Grand Bahama Shipyard Limited) 20 Maritime Reporter & Engineering News • SEPTEMBER 2016

MR #9 (18-25).indd 20 9/2/2016 11:22:00 AM

19

19

21

21