Page 63: of Maritime Reporter Magazine (March 2017)

U.S. Navy Quarterly & Maritime Simulation Technologies

Read this page in Pdf, Flash or Html5 edition of March 2017 Maritime Reporter Magazine

BALLAST WATER TECHNOLOGY ADVERTORIAL

Low Power BWTS will help Shipowners

By Tom Perlich,

Comply with New Sulfur Emissions Cap

Founder and President Ecochlor

At IMO MEPC 70 the 2020 implementation deadline considerations when evaluating UV treatment systems are was approved for a global sulfur emissions cap reduction that UV BWTS require treatment during both ballasting from 3.5% to 0.5%. This will ensure the reduction of sulfur and discharge, effectively doubling the power requirements, emissions for an estimated 70,000 ships worldwide. Clear- and multiple UV systems may be required in order to treat ly, installing a power-hungry ballast water treatment system the full ballast capacity on vessels with higher ? ow rates. (BWTS) would be counter to this objective. For BWTS using Electrochlorination (EC) technology,

The sulfur emission requirements can be met in one of the electricity required to power the electrolytic cell will be two ways: through using a low-sulfur compliant fuel or an directly related to the ballast ? ow rate, signi? cantly increas- approved equivalent method of lowering emissions. Invest- ing power requirements for higher ? ow rates. In addition, ment costs for fuel conversion or installing a scrubber can EC systems have temperature and water salinity limitations. be signi? cant and must be a consideration in the decision- At lower temperatures (less than 10°C) or low salinity lev- making process. In light of ballast water treatment regu- els (less than 18 PSU), the ef? ciency of the electrolytic cell latory obligations on the horizon, limiting the additional drops off drastically, requiring more power to treat to the power usage of a BWTS will be of great importance. The same standard in these conditions. Options to correct this power required for a BWTS during ballasting, and in some include using a heater to increase the temperature of the cases, during de-ballasting, can be considerable. The ship’s incoming water for slipstream systems or augmenting the existing generators typically supply this power; however, salinity of the incoming water. Either of these options will some treatment systems require so much power that an require associated pumps, electronics, and programming, additional, or an upgraded generator must be installed to which result in additional power.

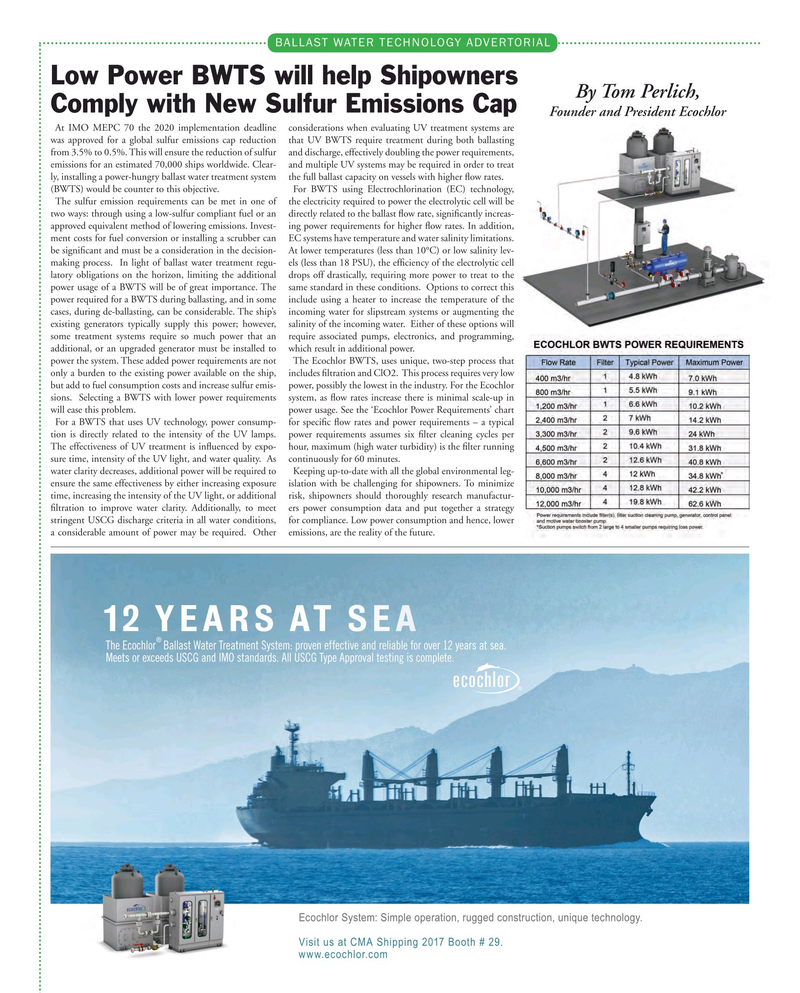

power the system. These added power requirements are not The Ecochlor BWTS, uses unique, two-step process that only a burden to the existing power available on the ship, includes ? ltration and ClO2. This process requires very low but add to fuel consumption costs and increase sulfur emis- power, possibly the lowest in the industry. For the Ecochlor sions. Selecting a BWTS with lower power requirements system, as ? ow rates increase there is minimal scale-up in will ease this problem. power usage. See the ‘Ecochlor Power Requirements’ chart

For a BWTS that uses UV technology, power consump- for speci? c ? ow rates and power requirements – a typical tion is directly related to the intensity of the UV lamps. power requirements assumes six ? lter cleaning cycles per

The effectiveness of UV treatment is in? uenced by expo- hour, maximum (high water turbidity) is the ? lter running sure time, intensity of the UV light, and water quality. As continuously for 60 minutes.

water clarity decreases, additional power will be required to Keeping up-to-date with all the global environmental leg- ensure the same effectiveness by either increasing exposure islation with be challenging for shipowners. To minimize time, increasing the intensity of the UV light, or additional risk, shipowners should thoroughly research manufactur- ? ltration to improve water clarity. Additionally, to meet ers power consumption data and put together a strategy stringent USCG discharge criteria in all water conditions, for compliance. Low power consumption and hence, lower a considerable amount of power may be required. Other emissions, are the reality of the future. ®

The Ecochlor Ballast Water Treatment System: proven effective and reliable for over 12 years at sea.

Meets or exceeds USCG and IMO standards. All USCG Type Approval testing is complete.

Ecochlor System: Simple operation, rugged construction, unique technology.

Visit us at CMA Shipping 2017 Booth # 29.

www.ecochlor.com

MR #3 (58-65).indd 63 MR #3 (58-65).indd 63 3/7/2017 12:05:01 PM3/7/2017 12:05:01 PM

62

62

64

64