Page 22: of Maritime Reporter Magazine (May 2017)

The Marine Propulsion Edition

Read this page in Pdf, Flash or Html5 edition of May 2017 Maritime Reporter Magazine

EYE ON DESIGN

About the Authors

Figure 3: Load Application.

Fritz Waldorf is Director of Sales and Matthew Schubert is a Senior Engineer-

Marketing for Viking Systems Interna- ing Manager at Viking Systems based in tional and based in Viking’s Houston, Viking’s Annapolis, MD of? ce. He has

TX of? ce. Viking assists shipyards, ship managed the analysis of multiple ATB designers and owner/operators with new build and conversion projects uti- ef? cient implementation of advanced lizing Viking’s advanced analysis proce- analysis tools for ? oating vessels and dures for both tug and barge structures structures. as implemented in SAGA.

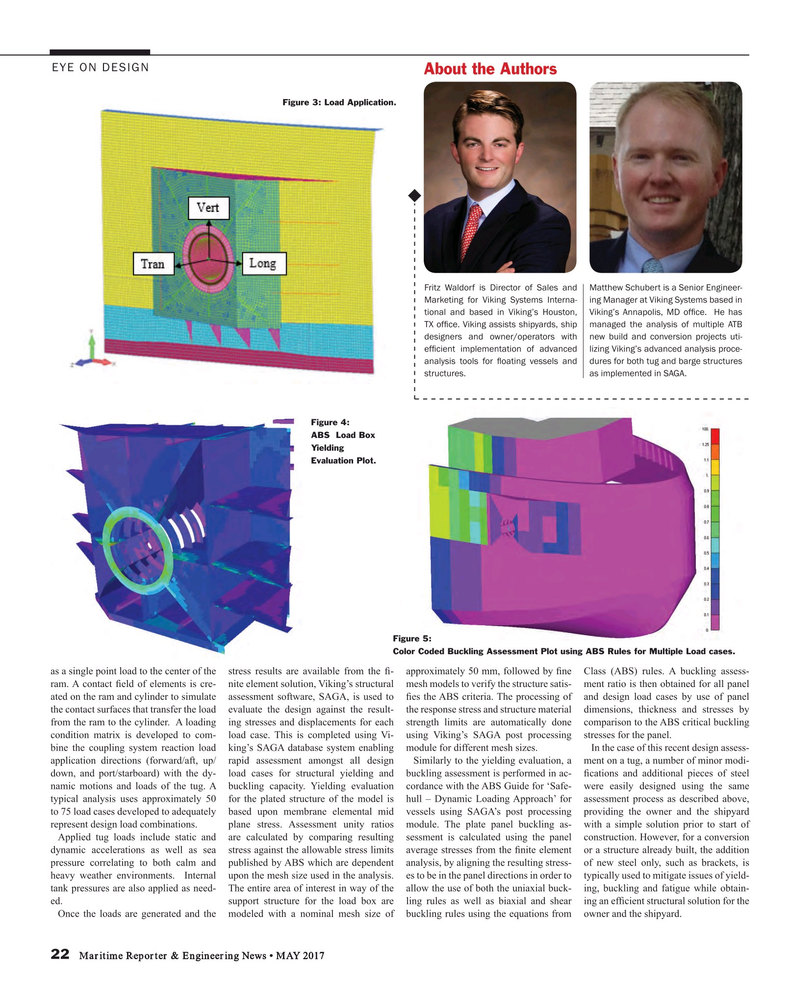

Figure 4:

ABS Load Box

Yielding

Evaluation Plot.

Figure 5:

Color Coded Buckling Assessment Plot using ABS Rules for Multiple Load cases.

as a single point load to the center of the stress results are available from the ? - approximately 50 mm, followed by ? ne Class (ABS) rules. A buckling assess- ram. A contact ? eld of elements is cre- nite element solution, Viking’s structural mesh models to verify the structure satis- ment ratio is then obtained for all panel ated on the ram and cylinder to simulate assessment software, SAGA, is used to ? es the ABS criteria. The processing of and design load cases by use of panel the contact surfaces that transfer the load evaluate the design against the result- the response stress and structure material dimensions, thickness and stresses by from the ram to the cylinder. A loading ing stresses and displacements for each strength limits are automatically done comparison to the ABS critical buckling condition matrix is developed to com- load case. This is completed using Vi- using Viking’s SAGA post processing stresses for the panel. bine the coupling system reaction load king’s SAGA database system enabling module for different mesh sizes. In the case of this recent design assess- application directions (forward/aft, up/ rapid assessment amongst all design Similarly to the yielding evaluation, a ment on a tug, a number of minor modi- down, and port/starboard) with the dy- load cases for structural yielding and buckling assessment is performed in ac- ? cations and additional pieces of steel namic motions and loads of the tug. A buckling capacity. Yielding evaluation cordance with the ABS Guide for ‘Safe- were easily designed using the same typical analysis uses approximately 50 for the plated structure of the model is hull – Dynamic Loading Approach’ for assessment process as described above, to 75 load cases developed to adequately based upon membrane elemental mid vessels using SAGA’s post processing providing the owner and the shipyard represent design load combinations. plane stress. Assessment unity ratios module. The plate panel buckling as- with a simple solution prior to start of

Applied tug loads include static and are calculated by comparing resulting sessment is calculated using the panel construction. However, for a conversion dynamic accelerations as well as sea stress against the allowable stress limits average stresses from the ? nite element or a structure already built, the addition pressure correlating to both calm and published by ABS which are dependent analysis, by aligning the resulting stress- of new steel only, such as brackets, is heavy weather environments. Internal upon the mesh size used in the analysis. es to be in the panel directions in order to typically used to mitigate issues of yield- tank pressures are also applied as need- The entire area of interest in way of the allow the use of both the uniaxial buck- ing, buckling and fatigue while obtain- ed. support structure for the load box are ling rules as well as biaxial and shear ing an ef? cient structural solution for the

Once the loads are generated and the modeled with a nominal mesh size of buckling rules using the equations from owner and the shipyard.

22 Maritime Reporter & Engineering News • MAY 2017

MR #5 (18-25).indd 22 MR #5 (18-25).indd 22 5/3/2017 8:01:53 PM5/3/2017 8:01:53 PM

21

21

23

23