Page 56: of Maritime Reporter Magazine (May 2017)

The Marine Propulsion Edition

Read this page in Pdf, Flash or Html5 edition of May 2017 Maritime Reporter Magazine

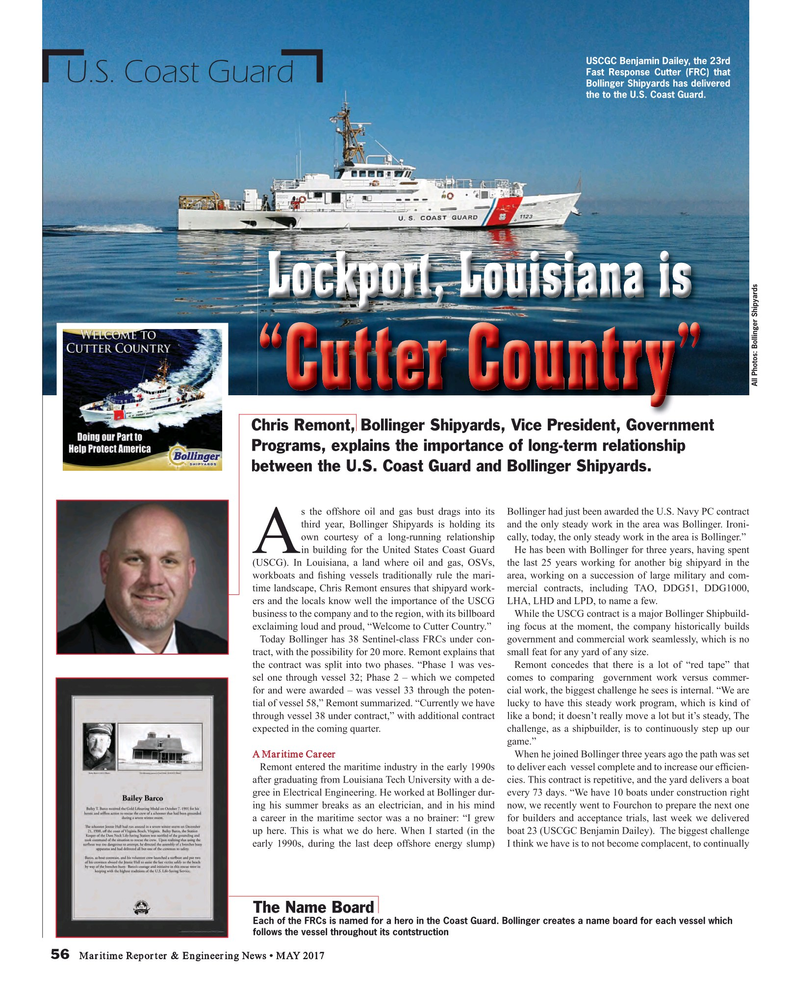

USCGC Benjamin Dailey, the 23rd

Fast Response Cutter (FRC) that

U.S. Coast Guard

Bollinger Shipyards has delivered the to the U.S. Coast Guard.

All Photos: Bollinger Shipyards

Chris Remont, Bollinger Shipyards, Vice President, Government

Programs, explains the importance of long-term relationship between the U.S. Coast Guard and Bollinger Shipyards.

s the offshore oil and gas bust drags into its Bollinger had just been awarded the U.S. Navy PC contract third year, Bollinger Shipyards is holding its and the only steady work in the area was Bollinger. Ironi- own courtesy of a long-running relationship cally, today, the only steady work in the area is Bollinger.”

Ain building for the United States Coast Guard He has been with Bollinger for three years, having spent (USCG). In Louisiana, a land where oil and gas, OSVs, the last 25 years working for another big shipyard in the workboats and ? shing vessels traditionally rule the mari- area, working on a succession of large military and com- time landscape, Chris Remont ensures that shipyard work- mercial contracts, including TAO, DDG51, DDG1000, ers and the locals know well the importance of the USCG LHA, LHD and LPD, to name a few.

business to the company and to the region, with its billboard While the USCG contract is a major Bollinger Shipbuild- exclaiming loud and proud, “Welcome to Cutter Country.” ing focus at the moment, the company historically builds

Today Bollinger has 38 Sentinel-class FRCs under con- government and commercial work seamlessly, which is no tract, with the possibility for 20 more. Remont explains that small feat for any yard of any size.

the contract was split into two phases. “Phase 1 was ves- Remont concedes that there is a lot of “red tape” that sel one through vessel 32; Phase 2 – which we competed comes to comparing government work versus commer- for and were awarded – was vessel 33 through the poten- cial work, the biggest challenge he sees is internal. “We are tial of vessel 58,” Remont summarized. “Currently we have lucky to have this steady work program, which is kind of through vessel 38 under contract,” with additional contract like a bond; it doesn’t really move a lot but it’s steady, The expected in the coming quarter. challenge, as a shipbuilder, is to continuously step up our game.”

A Maritime Career When he joined Bollinger three years ago the path was set

Remont entered the maritime industry in the early 1990s to deliver each vessel complete and to increase our ef? cien- after graduating from Louisiana Tech University with a de- cies. This contract is repetitive, and the yard delivers a boat gree in Electrical Engineering. He worked at Bollinger dur- every 73 days. “We have 10 boats under construction right ing his summer breaks as an electrician, and in his mind now, we recently went to Fourchon to prepare the next one a career in the maritime sector was a no brainer: “I grew for builders and acceptance trials, last week we delivered up here. This is what we do here. When I started (in the boat 23 (USCGC Benjamin Dailey). The biggest challenge early 1990s, during the last deep offshore energy slump) I think we have is to not become complacent, to continually

The Name Board

Each of the FRCs is named for a hero in the Coast Guard. Bollinger creates a name board for each vessel which follows the vessel throughout its contstruction 56 Maritime Reporter & Engineering News • MAY 2017

MR #5 (50-57).indd 56 MR #5 (50-57).indd 56 5/5/2017 1:27:56 PM5/5/2017 1:27:56 PM

55

55

57

57