Page 76: of Maritime Reporter Magazine (October 2017)

The Marine Design Annual

Read this page in Pdf, Flash or Html5 edition of October 2017 Maritime Reporter Magazine

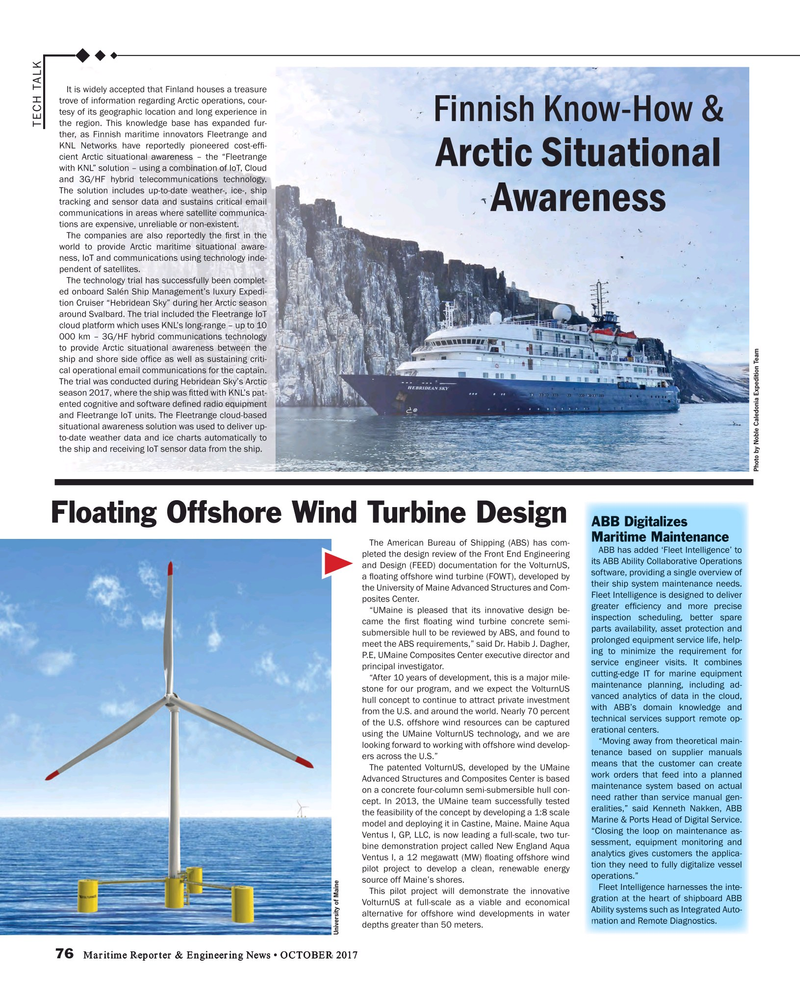

It is widely accepted that Finland houses a treasure trove of information regarding Arctic operations, cour- tesy of its geographic location and long experience in

Finnish Know-How & the region. This knowledge base has expanded fur-

TECH TALK ther, as Finnish maritime innovators Fleetrange and

KNL Networks have reportedly pioneered cost-ef? - cient Arctic situational awareness – the “Fleetrange

Arctic Situational with KNL” solution – using a combination of IoT, Cloud and 3G/HF hybrid telecommunications technology.

The solution includes up-to-date weather-, ice-, ship tracking and sensor data and sustains critical email

Awareness communications in areas where satellite communica- tions are expensive, unreliable or non-existent.

The companies are also reportedly the ? rst in the world to provide Arctic maritime situational aware- ness, IoT and communications using technology inde- pendent of satellites.

The technology trial has successfully been complet- ed onboard Salén Ship Management’s luxury Expedi- tion Cruiser “Hebridean Sky” during her Arctic season around Svalbard. The trial included the Fleetrange IoT cloud platform which uses KNL’s long-range – up to 10 000 km – 3G/HF hybrid communications technology to provide Arctic situational awareness between the ship and shore side of? ce as well as sustaining criti- cal operational email communications for the captain.

The trial was conducted during Hebridean Sky’s Arctic season 2017, where the ship was ? tted with KNL’s pat- ented cognitive and software de? ned radio equipment and Fleetrange IoT units. The Fleetrange cloud-based situational awareness solution was used to deliver up- to-date weather data and ice charts automatically to the ship and receiving IoT sensor data from the ship.

Photo by Noble Caledonia Expedition Team

Floating Offshore Wind Turbine Design

A A A A ABB Digitalizes

M M Maritime Maintenance

The American Bureau of Shipping (ABS) has com-

ABB has added ‘Fleet Intelligence’ to o o pleted the design review of the Front End Engineering it its ABB Ability Collaborative Operations s s and Design (FEED) documentation for the VolturnUS, s s s s software, providing a single overview of f f f a ? oating offshore wind turbine (FOWT), developed by t t t their ship system maintenance needs s. . the University of Maine Advanced Structures and Com-

F F Fleet Intelligence is designed to deliver r r posites Center.

g g g greater ef? ciency and more precise e e “UMaine is pleased that its innovative design be- in inspection scheduling, better spare e e came the ? rst ? oating wind turbine concrete semi- p p parts availability, asset protection and d d submersible hull to be reviewed by ABS, and found to p p prolonged equipment service life, help p- - - meet the ABS requirements,” said Dr. Habib J. Dagher, in ing to minimize the requirement for r r

P.E, UMaine Composites Center executive director and s s s s service engineer visits. It combines s s principal investigator. c c c cutting-edge IT for marine equipment t t “After 10 years of development, this is a major mile- m m maintenance planning, including ad- - - stone for our program, and we expect the VolturnUS v v v v vanced analytics of data in the cloud, , hull concept to continue to attract private investment w w w w with ABB’s domain knowledge and d d from the U.S. and around the world. Nearly 70 percent te t t technical services support remote op p- - - of the U.S. offshore wind resources can be captured e e e erational centers.

using the UMaine VolturnUS technology, and we are “Moving away from theoretical main- - - looking forward to working with offshore wind develop- te t t tenance based on supplier manuals s s ers across the U.S.” m m means that the customer can create e e

The patented VolturnUS, developed by the UMaine w w w w work orders that feed into a planned d d

Advanced Structures and Composites Center is based m m maintenance system based on actua al l on a concrete four-column semi-submersible hull con- n n need rather than service manual gen- - - cept. In 2013, the UMaine team successfully tested e e e eralities,” said Kenneth Nakken, ABB B B the feasibility of the concept by developing a 1:8 scale

M M Marine & Ports Head of Digital Service e. .

model and deploying it in Castine, Maine. Maine Aqua “ “Closing the loop on maintenance as s- - -

Ventus I, GP, LLC, is now leading a full-scale, two tur- s s s s sessment, equipment monitoring and d d bine demonstration project called New England Aqua a a a analytics gives customers the applica a- - -

Ventus I, a 12 megawatt (MW) ? oating offshore wind t t t tion they need to fully digitalize vesse el l pilot project to develop a clean, renewable energy o o o operations.” source off Maine’s shores.

Fleet Intelligence harnesses the inte e- - -

This pilot project will demonstrate the innovative g g g gration at the heart of shipboard ABB B B

VolturnUS at full-scale as a viable and economical

A A A A Ability systems such as Integrated Auto o- - - alternative for offshore wind developments in water agnost m ti ma ma on and Remot m m m mation and Remote e Di Diag gnostic ics. s. depths greater than 50 meters.

University of Maine 76 Maritime Reporter & Engineering News • OCTOBER 2017

MR #10 (74-81).indd 76 MR #10 (74-81).indd 76 10/4/2017 12:06:51 PM10/4/2017 12:06:51 PM

75

75

77

77