Page 105: of Maritime Reporter Magazine (November 2017)

The Workboat Edition

Read this page in Pdf, Flash or Html5 edition of November 2017 Maritime Reporter Magazine

TECH TALK

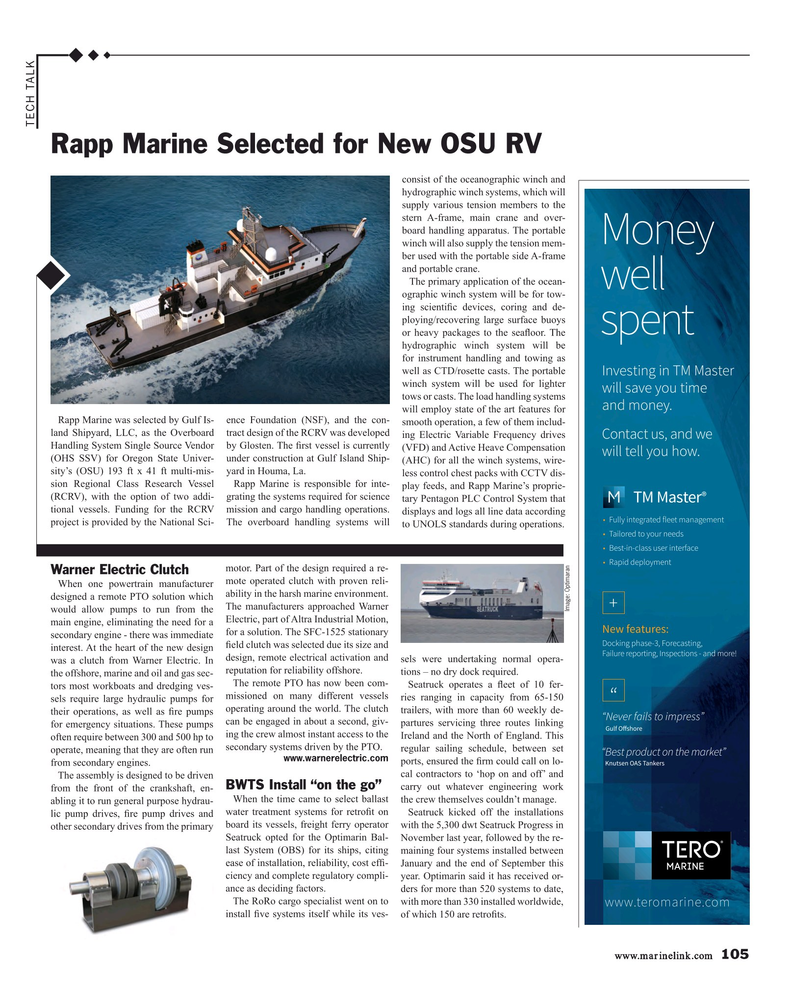

Rapp Marine Selected for New OSU RV consist of the oceanographic winch and hydrographic winch systems, which will supply various tension members to the stern A-frame, main crane and over- board handling apparatus. The portable

Money winch will also supply the tension mem- ber used with the portable side A-frame and portable crane.

The primary application of the ocean- well ographic winch system will be for tow- ing scienti? c devices, coring and de- ploying/recovering large surface buoys spent or heavy packages to the sea? oor. The hydrographic winch system will be for instrument handling and towing as well as CTD/rosette casts. The portable

Investing in TM Master winch system will be used for lighter will save you time tows or casts. The load handling systems and money. will employ state of the art features for

Rapp Marine was selected by Gulf Is- ence Foundation (NSF), and the con- smooth operation, a few of them includ- land Shipyard, LLC, as the Overboard tract design of the RCRV was developed ing Electric Variable Frequency drives

Contact us, and we

Handling System Single Source Vendor by Glosten. The ? rst vessel is currently (VFD) and Active Heave Compensation will tell you how.

(OHS SSV) for Oregon State Univer- under construction at Gulf Island Ship- (AHC) for all the winch systems, wire- sity’s (OSU) 193 ft x 41 ft multi-mis- yard in Houma, La. less control chest packs with CCTV dis- sion Regional Class Research Vessel Rapp Marine is responsible for inte- play feeds, and Rapp Marine’s proprie- (RCRV), with the option of two addi- grating the systems required for science tary Pentagon PLC Control System that ®

TM Master tional vessels. Funding for the RCRV mission and cargo handling operations. displays and logs all line data according • 2))6&+1"$/1"!?""1*+$"*"+1 project is provided by the National Sci- The overboard handling systems will to UNOLS standards during operations.

• Tailored to your needs • Best-in-class user interface • Rapid deployment motor. Part of the design required a re-

Warner Electric Clutch

When one powertrain manufacturer mote operated clutch with proven reli- designed a remote PTO solution which ability in the harsh marine environment. +

Image: Optimaran would allow pumps to run from the The manufacturers approached Warner main engine, eliminating the need for a Electric, part of Altra Industrial Motion,

New features: for a solution. The SFC-1525 stationary secondary engine - there was immediate

Docking phase-3, Forecasting, interest. At the heart of the new design ? eld clutch was selected due its size and

Failure reporting, Inspections - and more!

was a clutch from Warner Electric. In design, remote electrical activation and sels were undertaking normal opera- reputation for reliability offshore.

tions – no dry dock required.

the offshore, marine and oil and gas sec-

The remote PTO has now been com-

Seatruck operates a ? eet of 10 fer- tors most workboats and dredging ves- sels require large hydraulic pumps for missioned on many different vessels ries ranging in capacity from 65-150 their operations, as well as ? re pumps operating around the world. The clutch trailers, with more than 60 weekly de- “Never fails to impress” partures servicing three routes linking for emergency situations. These pumps can be engaged in about a second, giv- 2)#?0%,/" ing the crew almost instant access to the Ireland and the North of England. This often require between 300 and 500 hp to regular sailing schedule, between set operate, meaning that they are often run secondary systems driven by the PTO.

“Best product on the market” www.warnerelectric.com ports, ensured the ? rm could call on lo-

Knutsen OAS Tankers from secondary engines. cal contractors to ‘hop on and off’ and

The assembly is designed to be driven

BWTS Install “on the go” carry out whatever engineering work from the front of the crankshaft, en-

When the time came to select ballast the crew themselves couldn’t manage. abling it to run general purpose hydrau- lic pump drives, ? re pump drives and water treatment systems for retro? t on Seatruck kicked off the installations board its vessels, freight ferry operator with the 5,300 dwt Seatruck Progress in other secondary drives from the primary

Seatruck opted for the Optimarin Bal- November last year, followed by the re- last System (OBS) for its ships, citing maining four systems installed between ease of installation, reliability, cost ef? - January and the end of September this ciency and complete regulatory compli- year. Optimarin said it has received or- ance as deciding factors. ders for more than 520 systems to date,

The RoRo cargo specialist went on to with more than 330 installed worldwide, www.teromarine.com install ? ve systems itself while its ves- of which 150 are retro? ts. www.marinelink.com 105

MR #11 (98-105).indd 105 MR #11 (98-105).indd 105 11/6/2017 3:59:41 PM11/6/2017 3:59:41 PM

104

104

106

106