Page 46: of Maritime Reporter Magazine (April 2018)

Offshore Energy Annual

Read this page in Pdf, Flash or Html5 edition of April 2018 Maritime Reporter Magazine

TECH FILES

GustoMSC Evolves Chela ‘Smart’ Crane

Nearly two years ago GustoMSC in- troduced a smart crane for lifting and wireline operations under the drilling cantilever. Two years later, following industry feedback and further develop- ment, the equipment has evolved into

Chela, named after the Greek word for a crab’s claw. Chela offers an extra hand in operations, and due to its crab- like motion characteristics, it can reach below the cantilever as well as elevate towards the main deck, providing crane access to an area traditionally blocked by the cantilever when drilling.

Three key elements to enhance the overall ef? ciency of the drilling jack- up were used in the development of this piece of equipment: providing a large lifting envelope and wireline operation capabilities below the cantilever, easing

GustoMSC material handling to the platform and increasing safety for lifting over live ment on the drill ? oor and access to the a fully redundant main hoisting system, quence, no single failure, including the wells by applying high safety standards. work area without handshakes, Chela a key technical feature needed when failure of a hoisting rope, will lead to a

Besides the reduced human involve- features improved safety features with working over live wells. As a conse- high risk situation.

MOSES Connect Edition 10.12

Bentley Systems has released MO- rotate, align and offset Trimesh surfaces

SES Connect Edition 10.12 with key interactively and save pre-processing changes for added functionality and in- time in their analyses. These automa- tegrated solutions in meshing and pre- tion tools mitigate modelling risk from processing actions. Concurrently, the misaligned surfaces likely to result latest developments on interoperability when importing CAD geometries and options with SACS Connect Edition allow the designer to explore alterna- 11.2 promise a smoother modelling ex- tives ef? ciently while maintaining mesh perience in offshore operations. properties throughout.

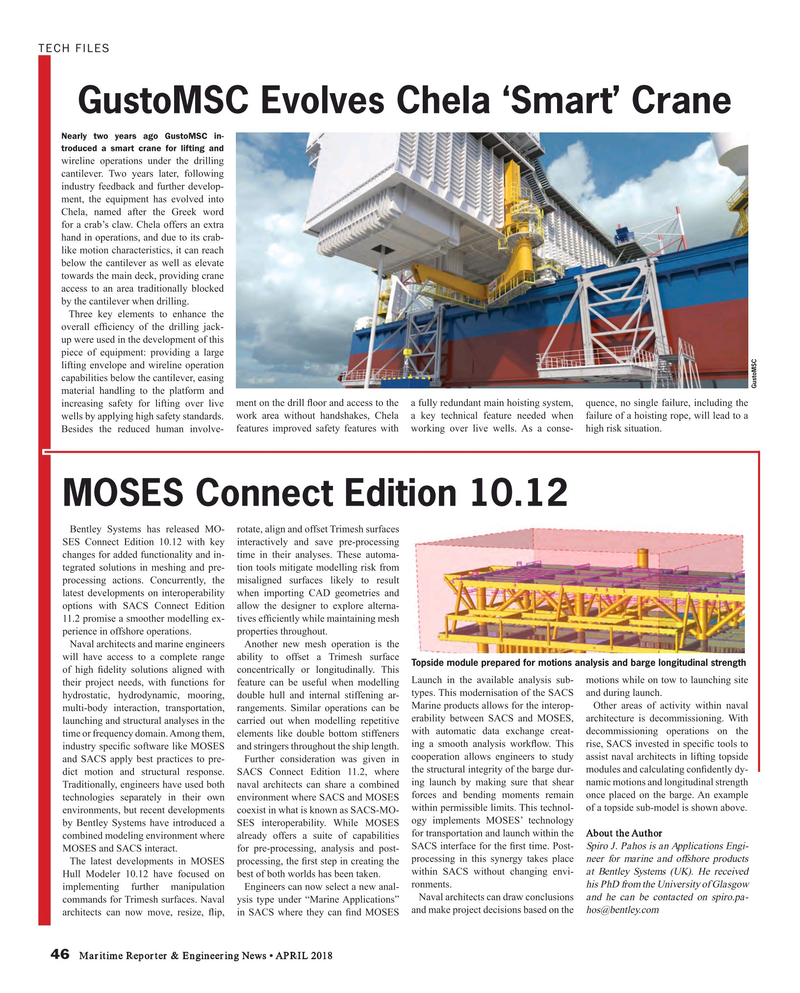

Naval architects and marine engineers Another new mesh operation is the will have access to a complete range ability to offset a Trimesh surface

Topside module prepared for motions analysis and barge longitudinal strength of high ? delity solutions aligned with concentrically or longitudinally. This their project needs, with functions for feature can be useful when modelling Launch in the available analysis sub- motions while on tow to launching site types. This modernisation of the SACS and during launch.

hydrostatic, hydrodynamic, mooring, double hull and internal stiffening ar- multi-body interaction, transportation, rangements. Similar operations can be Marine products allows for the interop- Other areas of activity within naval launching and structural analyses in the carried out when modelling repetitive erability between SACS and MOSES, architecture is decommissioning. With time or frequency domain. Among them, elements like double bottom stiffeners with automatic data exchange creat- decommissioning operations on the ing a smooth analysis work? ow. This rise, SACS invested in speci? c tools to industry speci? c software like MOSES and stringers throughout the ship length.

and SACS apply best practices to pre- Further consideration was given in cooperation allows engineers to study assist naval architects in lifting topside dict motion and structural response. SACS Connect Edition 11.2, where the structural integrity of the barge dur- modules and calculating con? dently dy-

Traditionally, engineers have used both naval architects can share a combined ing launch by making sure that shear namic motions and longitudinal strength technologies separately in their own environment where SACS and MOSES forces and bending moments remain once placed on the barge. An example within permissible limits. This technol- of a topside sub-model is shown above.

environments, but recent developments coexist in what is known as SACS-MO- by Bentley Systems have introduced a SES interoperability. While MOSES ogy implements MOSES’ technology combined modeling environment where already offers a suite of capabilities for transportation and launch within the About the Author

SACS interface for the ? rst time. Post- Spiro J. Pahos is an Applications Engi-

MOSES and SACS interact. for pre-processing, analysis and post-

The latest developments in MOSES processing, the ? rst step in creating the processing in this synergy takes place neer for marine and offshore products within SACS without changing envi- at Bentley Systems (UK). He received

Hull Modeler 10.12 have focused on best of both worlds has been taken.

ronments. his PhD from the University of Glasgow implementing further manipulation Engineers can now select a new anal-

Naval architects can draw conclusions and he can be contacted on spiro.pa- commands for Trimesh surfaces. Naval ysis type under “Marine Applications” architects can now move, resize, ? ip, in SACS where they can ? nd MOSES and make project decisions based on the [email protected] 46 Maritime Reporter & Engineering News • APRIL 2018

MR #4 (42-49).indd 46 MR #4 (42-49).indd 46 4/6/2018 9:24:35 AM4/6/2018 9:24:35 AM

45

45

47

47