Page 65: of Maritime Reporter Magazine (May 2018)

Marine Propulsion Edition

Read this page in Pdf, Flash or Html5 edition of May 2018 Maritime Reporter Magazine

RSC Bio Solutions’ RSC EnviroLogic

Photo: RSC Bio Solutions

Photo: ExxonMobil

Grease 2 WREP (Water Resistant Extreme

Pressure) is available in 35 lb / 15.875 kg

ExxonMobil’s Mobil SHC Aware HS: hydraulic oils pails, 14 oz / 396 g cartridges and 120 lb / formulated to offer protection in challenging environments.

54.43 kg kegs.

Panolin’s Word of Warning:

Not All EALs are the Same

According to Brandon Richards, CEO of PANOLIN America, Inc., not all EALs are the same. He noted that in early 2014 there were several reports about problems with overheating of stern tube bearings of new-build vessels on sea trials in the Far East occurring when EALs were used. Such problems were noticed in different vessel types, with different EAL makes, and with different shipbuild- ers; apparently they were not occurring in vessels ? lled using mineral-based stern tube lubricants. In addition, over the past year or so, there have been instances occurring of the leakage of some EALs from the stern tube, this time on vessels that had switched to using EALs, having previously been in service without a his- tory of stern tube problems when using mineral oils. On dry dock investigations, problems of wear and blistering of the stern tube seal lips became apparent and, in some instances, ‘stinking’ black sludge greeted the service engineers: this had to

Photo: Power Fuel Savers be scraped out of seal cavities and the seal oil feed pipes had to be blown through with compressed air to try to remove it. These problems are now being seen in the

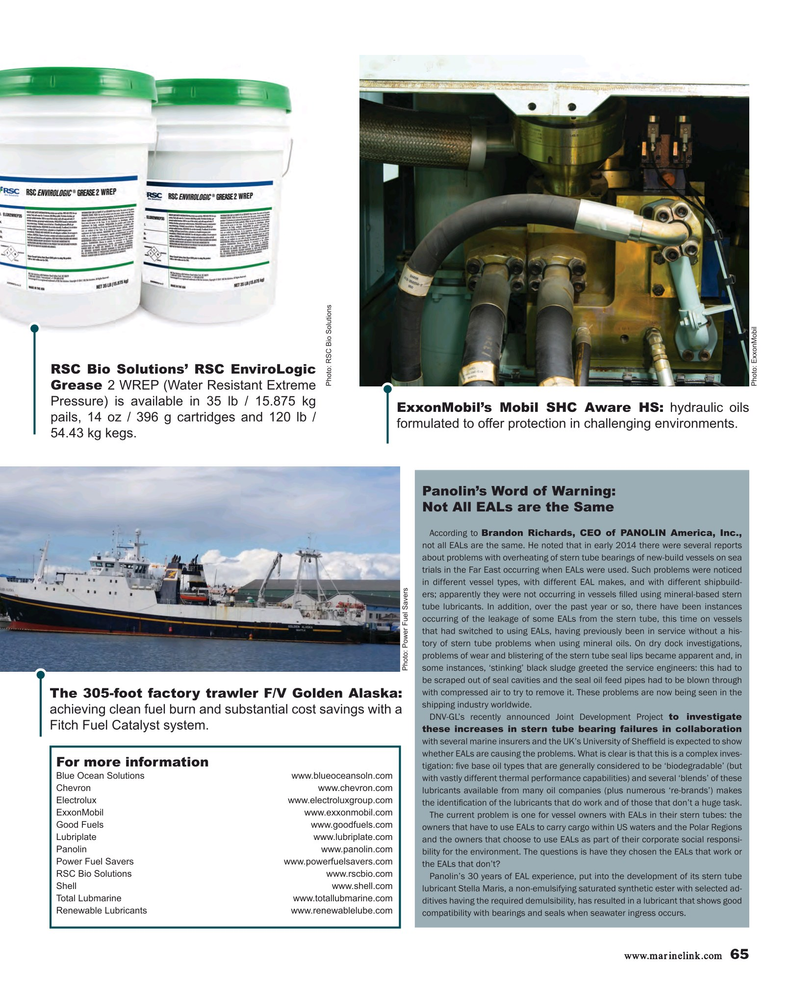

The 305-foot factory trawler F/V Golden Alaska: shipping industry worldwide.

achieving clean fuel burn and substantial cost savings with a

DNV-GL’s recently announced Joint Development Project to investigate

Fitch Fuel Catalyst system.

these increases in stern tube bearing failures in collaboration with several marine insurers and the UK’s University of Shef? eld is expected to show whether EALs are causing the problems. What is clear is that this is a complex inves-

For more information tigation: ? ve base oil types that are generally considered to be ‘biodegradable’ (but

Blue Ocean Solutions www.blueoceansoln.com with vastly different thermal performance capabilities) and several ‘blends’ of these

Chevron www.chevron.com lubricants available from many oil companies (plus numerous ‘re-brands’) makes

Electrolux www.electroluxgroup.com the identi? cation of the lubricants that do work and of those that don’t a huge task.

ExxonMobil www.exxonmobil.com

The current problem is one for vessel owners with EALs in their stern tubes: the

Good Fuels www.goodfuels.com owners that have to use EALs to carry cargo within US waters and the Polar Regions

Lubriplate www.lubriplate.com and the owners that choose to use EALs as part of their corporate social responsi-

Panolin www.panolin.com bility for the environment. The questions is have they chosen the EALs that work or

Power Fuel Savers www.powerfuelsavers.com the EALs that don’t?

RSC Bio Solutions www.rscbio.com

Panolin’s 30 years of EAL experience, put into the development of its stern tube

Shell www.shell.com lubricant Stella Maris, a non-emulsifying saturated synthetic ester with selected ad-

Total Lubmarine www.totallubmarine.com ditives having the required demulsibility, has resulted in a lubricant that shows good

Renewable Lubricants www.renewablelube.com compatibility with bearings and seals when seawater ingress occurs.

www.marinelink.com 65

MR #5 (58-65).indd 65 MR #5 (58-65).indd 65 5/3/2018 12:32:32 PM5/3/2018 12:32:32 PM

64

64

66

66