Page 112: of Maritime Reporter Magazine (August 2018)

The Shipyard Edition

Read this page in Pdf, Flash or Html5 edition of August 2018 Maritime Reporter Magazine

NEW TECH ? SMM 2018

SMM 2018 Preview

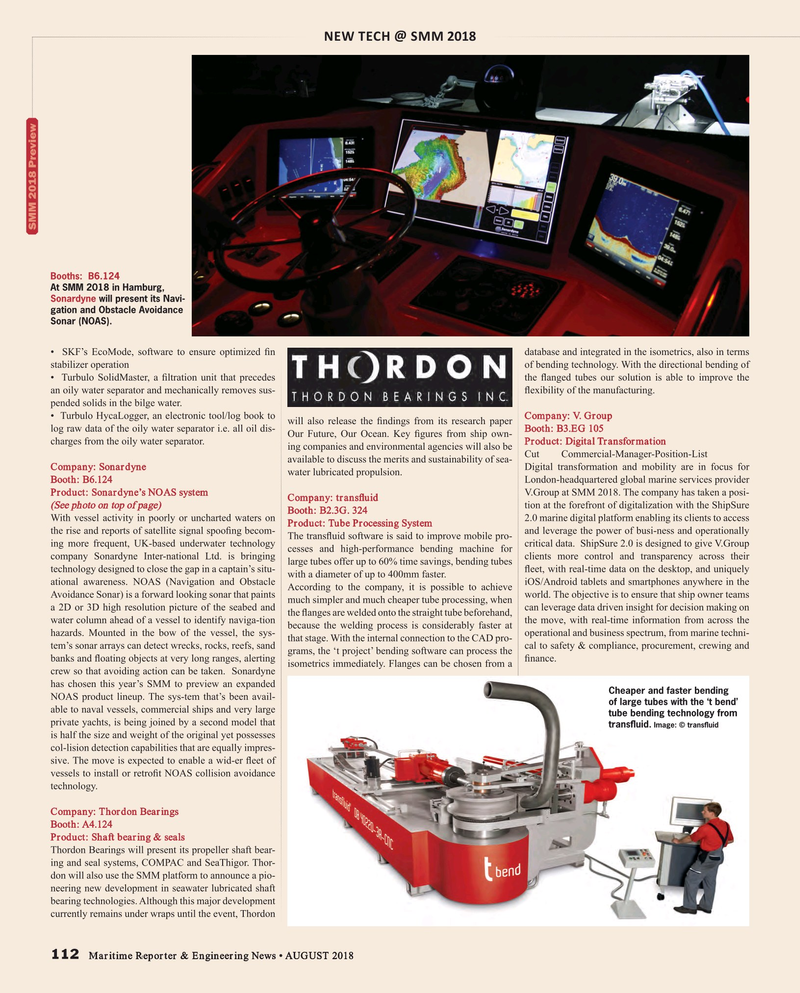

Booths: B6.124

At SMM 2018 in Hamburg,

Sonardyne will present its Navi- gation and Obstacle Avoidance

Sonar (NOAS).

• SKF’s EcoMode, software to ensure optimized ? n database and integrated in the isometrics, also in terms stabilizer operation of bending technology. With the directional bending of • Turbulo SolidMaster, a ? ltration unit that precedes the ? anged tubes our solution is able to improve the an oily water separator and mechanically removes sus- ? exibility of the manufacturing. pended solids in the bilge water. • Turbulo HycaLogger, an electronic tool/log book to will also release the ? ndings from its research paper Company: V. Group log raw data of the oily water separator i.e. all oil dis- Booth: B3.EG 105

Our Future, Our Ocean. Key ? gures from ship own- charges from the oily water separator. Product: Digital Transformation ing companies and environmental agencies will also be

Cut Commercial-Manager-Position-List available to discuss the merits and sustainability of sea-

Company: Sonardyne Digital transformation and mobility are in focus for water lubricated propulsion.

Booth: B6.124 London-headquartered global marine services provider

Product: Sonardyne’s NOAS system V.Group at SMM 2018. The company has taken a posi-

Company: trans? uid (See photo on top of page) tion at the forefront of digitalization with the ShipSure

Booth: B2.3G. 324

With vessel activity in poorly or uncharted waters on Product: Tube Processing System 2.0 marine digital platform enabling its clients to access the rise and reports of satellite signal spoo? ng becom- and leverage the power of busi-ness and operationally

The trans? uid software is said to improve mobile pro- ing more frequent, UK-based underwater technology cesses and high-performance bending machine for critical data. ShipSure 2.0 is designed to give V.Group company Sonardyne Inter-national Ltd. is bringing large tubes offer up to 60% time savings, bending tubes clients more control and transparency across their technology designed to close the gap in a captain’s situ- ? eet, with real-time data on the desktop, and uniquely with a diameter of up to 400mm faster.

ational awareness. NOAS (Navigation and Obstacle According to the company, it is possible to achieve iOS/Android tablets and smartphones anywhere in the

Avoidance Sonar) is a forward looking sonar that paints world. The objective is to ensure that ship owner teams much simpler and much cheaper tube processing, when a 2D or 3D high resolution picture of the seabed and the ? anges are welded onto the straight tube beforehand, can leverage data driven insight for decision making on water column ahead of a vessel to identify naviga-tion because the welding process is considerably faster at the move, with real-time information from across the hazards. Mounted in the bow of the vessel, the sys- operational and business spectrum, from marine techni- that stage. With the internal connection to the CAD pro- tem’s sonar arrays can detect wrecks, rocks, reefs, sand cal to safety & compliance, procurement, crewing and grams, the ‘t project’ bending software can process the banks and ? oating objects at very long ranges, alerting ? nance. isometrics immediately. Flanges can be chosen from a crew so that avoiding action can be taken. Sonardyne has chosen this year’s SMM to preview an expanded

Cheaper and faster bending

NOAS product lineup. The sys-tem that’s been avail- of large tubes with the ‘t bend’ able to naval vessels, commercial ships and very large tube bending technology from private yachts, is being joined by a second model that trans

111

111

113

113