Page 78: of Maritime Reporter Magazine (August 2018)

The Shipyard Edition

Read this page in Pdf, Flash or Html5 edition of August 2018 Maritime Reporter Magazine

BALLAST WATER MANAGEMENT SYSTEMS

Components Testing:

The Quieter Side of the BWMS Discussion

BY WALTER POGGI, PRESIDENT, RETLIF TESTING LABORATORIES

Ballast Water Management Systems leads to the key question: Understanding the Test Plan meetings are invaluable. The laboratory have dominated industry news for years, “How are the system and its compo- To address such concerns before they team sees the equipment for a better un- with millions of words generated on de- nents actually tested?” become realities, the ? rst step of a derstanding of how it can be setup, en- veloping regulations, the approvals pro- Effective science-based testing, codi- BWMS test program ergized and operated during testing, and cess, as well as on international interpre- ? ed in a test plan is the smartest route to is the development of a test plan. The the customer’s engineering group gets a tation and implementation. Additional compliance. In this analogy, the lack of process is not simple, requires a mean- much fuller understanding of the actual volumes have been authored on USCG a test plan is like building a ship without ingful amount of testing that will take place.

interpretation and implementation of a rudder. It means a potential loss of fo- time, but will result in a lengthy but compliant systems. Amid this ongoing cus and direction, a serious enough void essential document. There are four basic • Test Plan Generation: Armed with typhoon of words, another area often that could turn the effort into what the steps involved. the information gathered during the on- gets lost in the shuf? e because of its testing world euphemistically terms, “a site visit, the laboratory’s engineering stability and consistency, but is no less misguided science experiment.” • Initial Documentation Review: The team oversees the generation of the test important in the grand scheme of things: Nor is the lack of a test plan what the laboratory will have technical documen- plan. This process normally takes about

Electrical and environmental simulation customer wants. Customers want the tation which it used in the generation two weeks and results in a document of testing and compliance of BWMS com- most economic testing program that will of the quotation for the needed testing. approximately 175 to 200 pages. The ponents. demonstrate compliance with the speci- Once an order is received to perform document addresses test setups, modes

In 2016, when Retlif Testing Laborato- ? cations, and ultimately result in mar- testing, an engineering team typically of operation, monitoring technics and ries became the ? rst “Sub Lab” approved ket access. “Both the customer and the composed of one electrical and one me- pass/fail criteria in detail.

by the USCG for environmental simula- laboratory want a de? ned, cost effective chanical test engineer will review the tion testing related to BWMS, the indus- testing program, that for the customer documentation. This is done to better • General Approval: After the test try was becoming aware of the growing assures marketplace access a.s.a.p. The understand the equipment to be tested plan document is completed by the labo- undercurrent of both process and proto- laboratory wants well de? ned schedul- and to begin strategizing the testing ap- ratory, it is then circulated to both the col. Retlif, which currently has working ing of personnel and test instrumenta- proaches for each of the test methods. customer and the IL for the approval and relationships with ? ve of the USCG des- tion, because that provides the most ef? - sign off. Clearly at this point there can ignated Independent Laboratories (IL), cient operation,” said Scott Poggi, Retlif • Customer’s Manufacturing Facil- be give and take with slight modi? ca- led the way. Director of Operations. ity Visit: Next, the laboratory’s engi- tions made. However, the end result is a “As we all know, maritime operating And this is anathema to regulators and neering team will visit the customer’s document that is both customer and IL- conditions constitute a harsh and un- approving bodies. They want to review manufacturing facility. This visit is nor- approved which provides very de? ned forgiving environment.” Richard Re- a test report that is technically complete mally completed over two days, during and clear direction for the test program.

itz, Retlif Director of Engineering said. and “technically clear.” An acceptable which the laboratory engineering team “The acute and cumulative effects of test report must convey how each test interfaces with the customer’s in-house Environmental Sim & vibration, inclination, not to mention the was performed and how the equipment engineering. During these meetings is- Voltage Variation Testing extremes of temperature, directly impact under test (EUT) was set up, operated sues such as modes of operation and test Now let’s look at the basics of the en- the performance of maritime equipment and monitored. setups are discussed and de? ned. These vironmental simulation and the voltage performance from Voyage Data Record- variation testing ers to simple deck winches. The compo- that are performed on the component

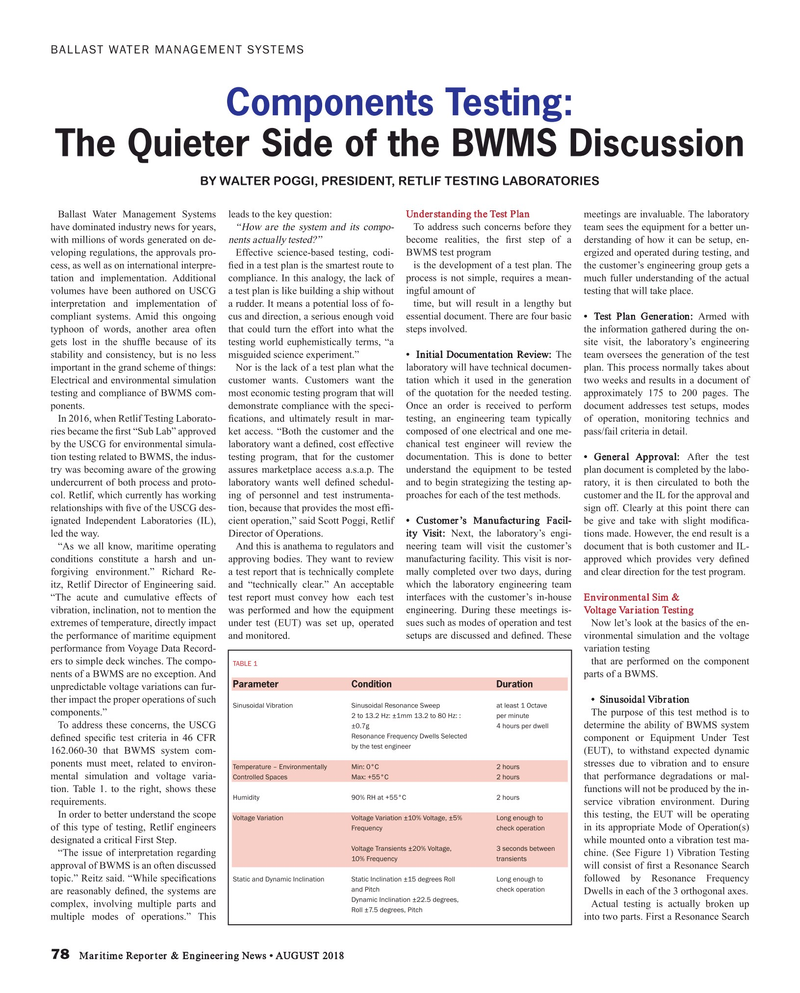

TABLE 1 nents of a BWMS are no exception. And parts of a BWMS.

Parameter Condition Duration unpredictable voltage variations can fur- ther impact the proper operations of such • Sinusoidal Vibration

Sinusoidal Vibration Sinusoidal Resonance Sweep at least 1 Octave components.” The purpose of this test method is to 2 to 13.2 Hz: ±1mm 13.2 to 80 Hz: : per minute

To address these concerns, the USCG determine the ability of BWMS system ±0.7g 4 hours per dwell Resonance Frequency Dwells Selected de? ned speci? c test criteria in 46 CFR component or Equipment Under Test by the test engineer 162.060-30 that BWMS system com- (EUT), to withstand expected dynamic ponents must meet, related to environ- stresses due to vibration and to ensure

Temperature – Environmentally Min: 0°C 2 hours mental simulation and voltage varia- that performance degradations or mal-

Controlled Spaces Max: +55°C 2 hours tion. Table 1. to the right, shows these functions will not be produced by the in-

Humidity 90% RH at +55°C 2 hours requirements. service vibration environment. During

In order to better understand the scope this testing, the EUT will be operating

Voltage Variation Voltage Variation ±10% Voltage, ±5% Long enough to of this type of testing, Retlif engineers in its appropriate Mode of Operation(s) operation Frequency check designated a critical First Step. while mounted onto a vibration test ma- Voltage Transients ±20% Voltage, 3 seconds between “The issue of interpretation regarding chine. (See Figure 1) Vibration Testing 10% Frequency transients approval of BWMS is an often discussed will consist of ? rst a Resonance Search topic.” Reitz said. “While speci? cations followed by Resonance Frequency

Static and Dynamic Inclination Static Inclination ±15 degrees Roll Long enough to and Pitch check operation are reasonably de? ned, the systems are Dwells in each of the 3 orthogonal axes.

Dynamic Inclination ±22.5 degrees, complex, involving multiple parts and Actual testing is actually broken up Roll ±7.5 degrees, Pitch multiple modes of operations.” This into two parts. First a Resonance Search 78 Maritime Reporter & Engineering News • AUGUST 2018

MR #8 (74-81).indd 78 MR #8 (74-81).indd 78 8/6/2018 12:37:04 PM8/6/2018 12:37:04 PM

77

77

79

79