Page 94: of Maritime Reporter Magazine (August 2018)

The Shipyard Edition

Read this page in Pdf, Flash or Html5 edition of August 2018 Maritime Reporter Magazine

TECH FILES

SKF Hydraulic Bolts

Damage caused by a propeller shaft with the ? ange connection between the misalignment problem and related ex- two shafts.

cessive vibrations and ? ange coupling

The team of technicians at the Ham- wear, is remedied with the aid of SKF burg shipyard had identi? ed the source

Supergrip hydraulic bolts.

of vibration as shaft misalignment and

While at sea in early May 2017, the they advised both the shipyard and crew of a Greek owned, Marshall Is- the ship owners on how to remove the lands registered 170,000 ton bulk car- existing ? ange coupling bolts with- rier became aware of unusually high out causing additional damage to the levels of mechanical vibration, the ori- ? ange. Unfortunately, the holes left by gin of which was eventually traced to the old bolts were found to be worn and the ship’s propeller shaft. Indeed, when this necessitated on-site machining.

metal debris was discovered in the lu- The ship owner contacted its partner brication system of the tail shaft, the J & E Papadopoulos SA, an of? cial problem was considered severe enough distributor of SKF products based at to prompt an immediate request for the Greek port of Piraeus, to ? nd a so- docking at the closest facility – in this lution and coordinate the repair work. case, a shipyard in Hamburg, Germany. Since the bolts needed to be installed

Propeller shaft problems are among and removed several times during the the most critical issues a shipping com- repair operation, J & E Papadopoulos pany has to deal with, and in virtually SA, along with SKF, recommended the all cases immediate remedial action is use of hydraulic bolts – in particular required to avoid further damage and SKF’s Supergrip Bolts, which eliminate total loss of propulsion. Wear, fatigue, uncertainties about the length of down- and corrosion can weaken the tail shaft time needed for removing and installing of a vessel, eventually causing crack- bolts during unscheduled outages. ing and fractures. In the most serious of Supergrip Bolts are a solution for cases, unless emergency maintenance is connecting ? ange connections, includ- undertaken, the tail shaft can undergo a ing ? ange couplings. The bolt is hy- catastrophic failure, resulting in the loss draulically expanded and tightened of the ship’s propeller. Clearly, this can into the coupling bolt hole using a set lead to signi? cant delays to the ship’s of portable tools, eliminating the need itinerary and, of course, enormous costs of nitrogen-cooling bolts to achieve an for the owners. interference ? t.

To reduce the risk of such incidents, The bolt holes on the bulk carrier’s shipping companies must dock their intermediate shaft couplings were sim- vessels at ? ve-year intervals for inspec- ply line-bored for initial installation, tion, a process that sometimes involves as the expandable bolt sleeves were, to removal of the complete shaft, a task re- perfectly match each individual hole. quiring the withdrawal of the coupling’s Releasing the expansion pressure al- heavy-duty bolts. Any complications lowed the bolts to be easily withdrawn

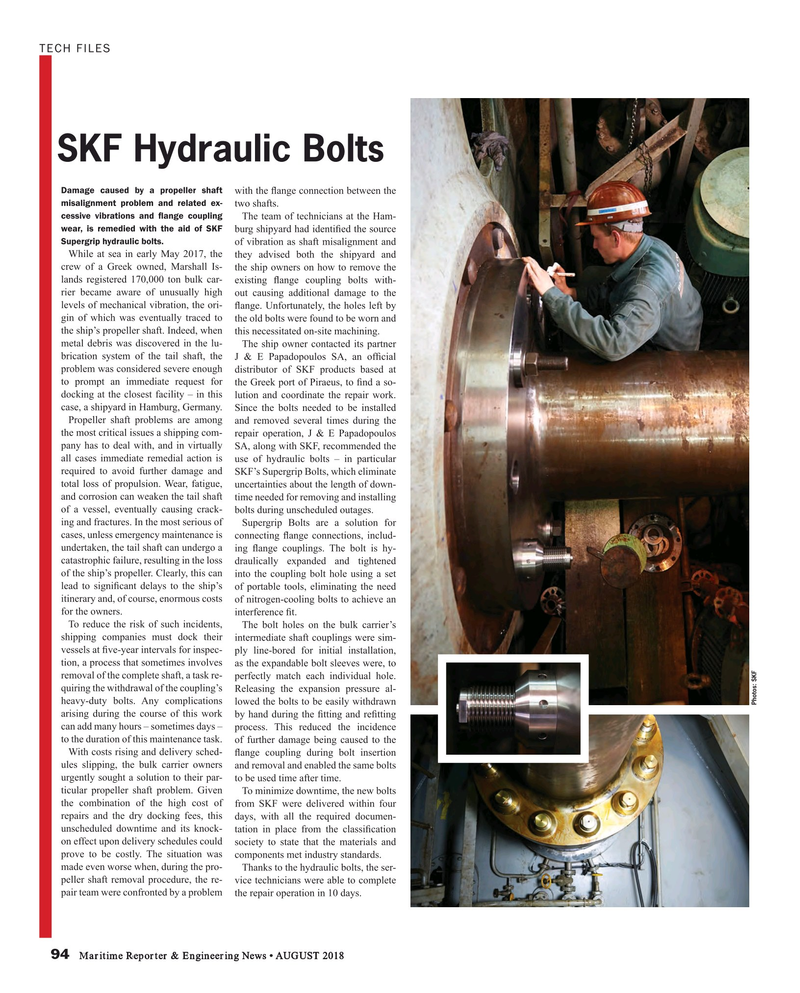

Photos: SKF arising during the course of this work by hand during the ? tting and re? tting can add many hours – sometimes days – process. This reduced the incidence to the duration of this maintenance task. of further damage being caused to the

With costs rising and delivery sched- ? ange coupling during bolt insertion ules slipping, the bulk carrier owners and removal and enabled the same bolts urgently sought a solution to their par- to be used time after time.

ticular propeller shaft problem. Given To minimize downtime, the new bolts the combination of the high cost of from SKF were delivered within four repairs and the dry docking fees, this days, with all the required documen- unscheduled downtime and its knock- tation in place from the classi? cation on effect upon delivery schedules could society to state that the materials and prove to be costly. The situation was components met industry standards. made even worse when, during the pro- Thanks to the hydraulic bolts, the ser- peller shaft removal procedure, the re- vice technicians were able to complete pair team were confronted by a problem the repair operation in 10 days.

94 Maritime Reporter & Engineering News • AUGUST 2018

MR #8 (90-97).indd 94 MR #8 (90-97).indd 94 8/7/2018 12:45:18 PM8/7/2018 12:45:18 PM

93

93

95

95