Page 54: of Maritime Reporter Magazine (June 2020)

2020 Yearbook

Read this page in Pdf, Flash or Html5 edition of June 2020 Maritime Reporter Magazine

Tech Files

Product & System Innovations

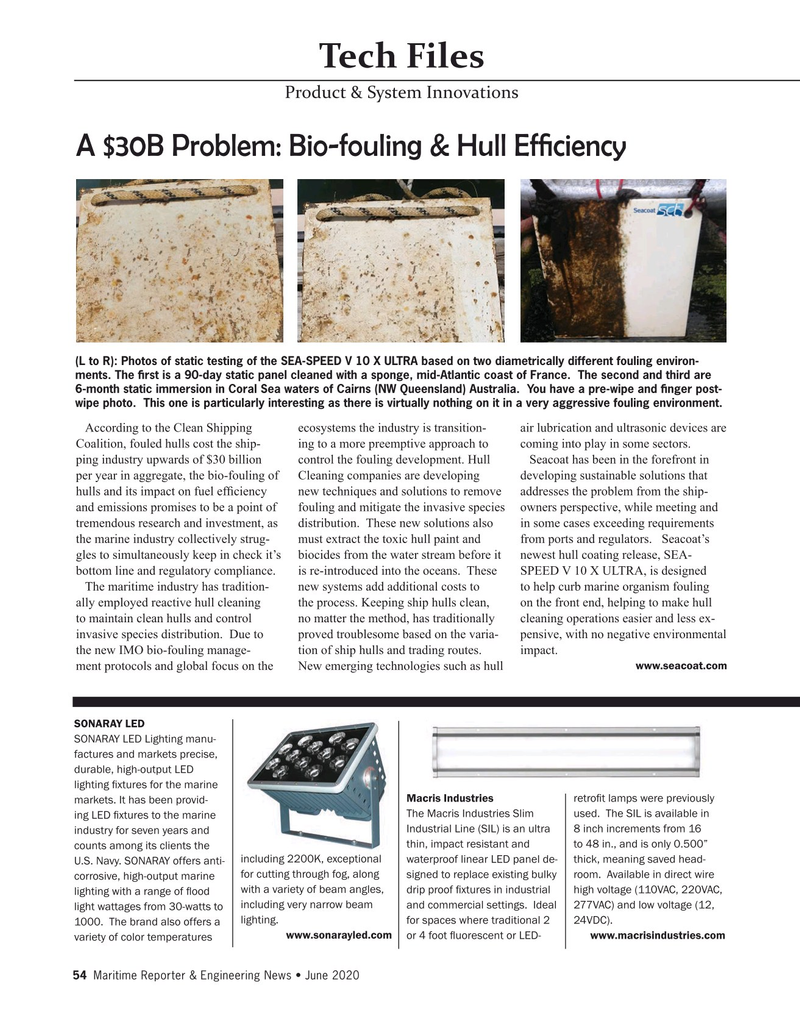

A $30B Problem: Bio-fouling & Hull Effciency (L to R): Photos of static testing of the SEA-SPEED V 10 X ULTRA based on two diametrically different fouling environ- ments. The frst is a 90-day static panel cleaned with a sponge, mid-Atlantic coast of France. The second and third are 6-month static immersion in Coral Sea waters of Cairns (NW Queensland) Australia. You have a pre-wipe and fnger post- wipe photo. This one is particularly interesting as there is virtually nothing on it in a very aggressive fouling environment.

According to the Clean Shipping ecosystems the industry is transition- air lubrication and ultrasonic devices are

Coalition, fouled hulls cost the ship- ing to a more preemptive approach to coming into play in some sectors.

ping industry upwards of $30 billion control the fouling development. Hull Seacoat has been in the forefront in per year in aggregate, the bio-fouling of Cleaning companies are developing developing sustainable solutions that hulls and its impact on fuel effciency new techniques and solutions to remove addresses the problem from the ship- and emissions promises to be a point of fouling and mitigate the invasive species owners perspective, while meeting and tremendous research and investment, as distribution. These new solutions also in some cases exceeding requirements the marine industry collectively strug- must extract the toxic hull paint and from ports and regulators. Seacoat’s gles to simultaneously keep in check it’s biocides from the water stream before it newest hull coating release, SEA- bottom line and regulatory compliance. is re-introduced into the oceans. These SPEED V 10 X ULTRA, is designed

The maritime industry has tradition- new systems add additional costs to to help curb marine organism fouling ally employed reactive hull cleaning the process. Keeping ship hulls clean, on the front end, helping to make hull to maintain clean hulls and control no matter the method, has traditionally cleaning operations easier and less ex- invasive species distribution. Due to proved troublesome based on the varia- pensive, with no negative environmental the new IMO bio-fouling manage- tion of ship hulls and trading routes. impact.

www.seacoat.com ment protocols and global focus on the New emerging technologies such as hull

SONARAY LED

SONARAY LED Lighting manu- factures and markets precise, durable, high-output LED lighting fxtures for the marine

Macris Industries retroft lamps were previously markets. It has been provid-

The Macris Industries Slim used. The SIL is available in ing LED fxtures to the marine

Industrial Line (SIL) is an ultra 8 inch increments from 16 industry for seven years and thin, impact resistant and to 48 in., and is only 0.500” counts among its clients the including 2200K, exceptional waterproof linear LED panel de- thick, meaning saved head-

U.S. Navy. SONARAY offers anti- for cutting through fog, along signed to replace existing bulky room. Available in direct wire corrosive, high-output marine with a variety of beam angles, drip proof fxtures in industrial high voltage (110VAC, 220VAC, lighting with a range of food including very narrow beam and commercial settings. Ideal 277VAC) and low voltage (12, light wattages from 30-watts to lighting. for spaces where traditional 2 24VDC).

1000. The brand also offers a www.sonarayled.com or 4 foot fuorescent or LED- www.macrisindustries.com variety of color temperatures 54 Maritime Reporter & Engineering News • June 2020

53

53

55

55