Page 10: of Maritime Reporter Magazine (July 2020)

Maritime Power Edition

Read this page in Pdf, Flash or Html5 edition of July 2020 Maritime Reporter Magazine

Leading Of

Capturing the Systems and Physics of a $3b Structure hen Swiss-based Allseas Group wanted Developed by Montreal-based CM Labs, Vortex Studio is a to build a simulation model to capture leading simulation platform for dynamics simulation and 3D the systems and physics of its $3 billion visualization. Allseas’ ultimate simulation objectives were

Pioneering Spirit vessel, it called on CM threefold:

W

Labs Simulations to provide the solution. • Train vessel operators for teamwork-intensive activities

With the help of CM Labs’ Vortex Stu- such as ballast control, top side lift system, and steering, dio simulation software platform, Allseas • Test new concepts and developments in support of con- was able to build extensible simulations that could be en- tinuous R&D, hanced and modifed throughout the life of the vessel. • Provide project teams with a tool for visualizing dif-

The world’s largest vessel really does have to be seen up ferent projects (e.g., to assess clearance for operations, close to be believed. The massive heavy-lift and pipelay identify camera locations, etc.).

vessel, Pioneering Spirit, is so ambitious that it was only de- As mechanical engineers, the Allseas R&D engineering re- livered nearly 30 years after its initial design. Designed by alized that developing their own 3D simulation toolset would

Swiss-based Allseas Group, the 382-m (1,253 ft) long, 124-m involve far too much effort. Although they had extensive ex- (407 ft) wide vessel is the largest in the world. Created for perience performing engineering-grade simulations in MAT- the single-lift installation and removal of large oil and gas LAB, detailed hydraulics, they had always found it necessary platforms and installation of record-weight pipelines, Pioneer to sacrifce the scale of the simulation if they wanted to in-

Spirit can lift entire platform topsides of up to 48,000t and clude mechanical dynamics.

jackets up to 20,000t in a single piece. This reduces offshore “Our goal was to obtain a realistically responding vessel work associated with installation and decommissioning by with Vortex Studio and use lower-level tools for detailed hy- moving the work onshore where it is safer and more cost- draulic or structural computations as needed. All the specifc effective. components, we know a lot about, but putting them all to-

Due to the vessel’s complexity, and the continuous engi- gether in a full-scale model is just not feasible.” neering required to build it, no simulation model has ever “Vortex Studio took a lot of work out of our hands,” te been developed to capture all the systems and physics of the Voortwis adds, “namely on the dynamics simulation and 3D $3 billion megastructure. “That was basically our goal with visualization side.” One of the strengths of Vortex Studio is

Vortex Studio,” said Allseas R&D engineer Ate te Voortwis. in accelerating design time and reduction of costly feld test-

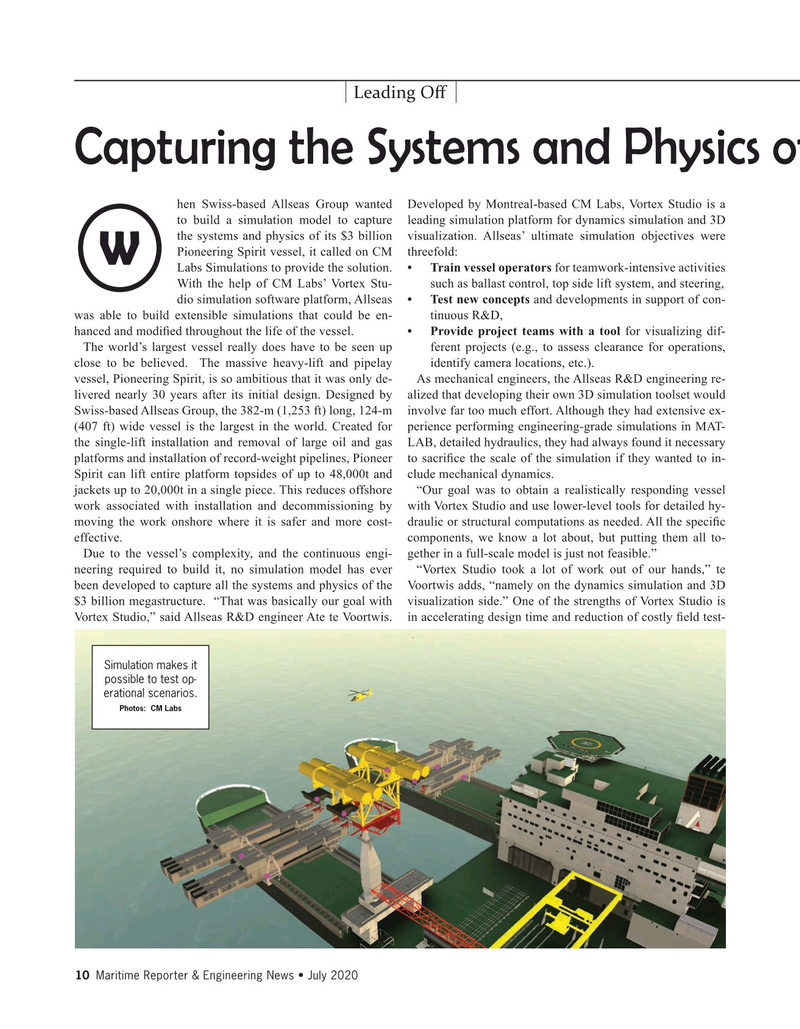

Simulation makes it possible to test op- erational scenarios.

Photos: CM Labs 10 Maritime Reporter & Engineering News • July 2020

9

9

11

11