Page 42: of Maritime Reporter Magazine (August 2021)

The Shipyard Annual

Read this page in Pdf, Flash or Html5 edition of August 2021 Maritime Reporter Magazine

SHIPBUILDING THE SHIPYARDS

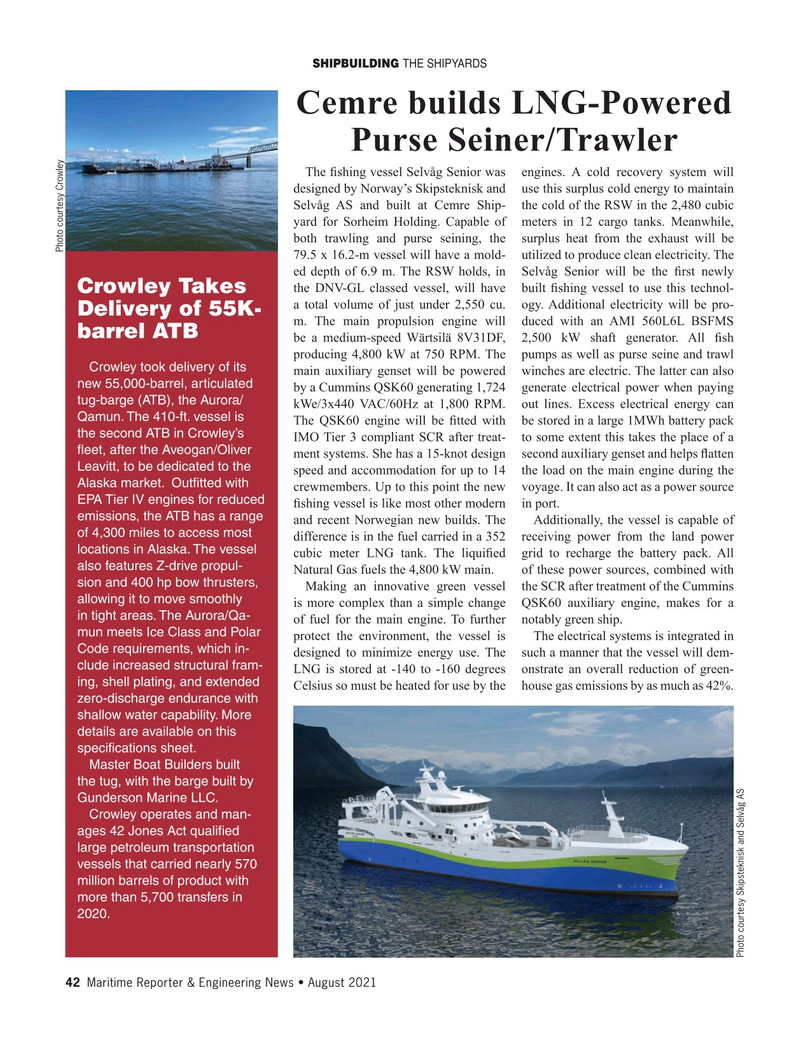

Cemre builds LNG-Powered

Purse Seiner/Trawler

The ? shing vessel Selvåg Senior was engines. A cold recovery system will designed by Norway’s Skipsteknisk and use this surplus cold energy to maintain

Selvåg AS and built at Cemre Ship- the cold of the RSW in the 2,480 cubic yard for Sorheim Holding. Capable of meters in 12 cargo tanks. Meanwhile, both trawling and purse seining, the surplus heat from the exhaust will be

Photo courtesy Crowley 79.5 x 16.2-m vessel will have a mold- utilized to produce clean electricity. The ed depth of 6.9 m. The RSW holds, in Selvåg Senior will be the ? rst newly the DNV-GL classed vessel, will have built ? shing vessel to use this technol-

Crowley Takes a total volume of just under 2,550 cu. ogy. Additional electricity will be pro-

Delivery of 55K- m. The main propulsion engine will duced with an AMI 560L6L BSFMS barrel ATB be a medium-speed Wärtsilä 8V31DF, 2,500 kW shaft generator. All ? sh producing 4,800 kW at 750 RPM. The pumps as well as purse seine and trawl

Crowley took delivery of its main auxiliary genset will be powered winches are electric. The latter can also new 55,000-barrel, articulated by a Cummins QSK60 generating 1,724 generate electrical power when paying tug-barge (ATB), the Aurora/ kWe/3x440 VAC/60Hz at 1,800 RPM. out lines. Excess electrical energy can

Qamun. The 410-ft. vessel is

The QSK60 engine will be ? tted with be stored in a large 1MWh battery pack the second ATB in Crowley’s

IMO Tier 3 compliant SCR after treat- to some extent this takes the place of a ? eet, after the Aveogan/Oliver ment systems. She has a 15-knot design second auxiliary genset and helps ? atten

Leavitt, to be dedicated to the speed and accommodation for up to 14 the load on the main engine during the

Alaska market. Out? tted with crewmembers. Up to this point the new voyage. It can also act as a power source

EPA Tier IV engines for reduced ? shing vessel is like most other modern in port. emissions, the ATB has a range and recent Norwegian new builds. The Additionally, the vessel is capable of of 4,300 miles to access most difference is in the fuel carried in a 352 receiving power from the land power locations in Alaska. The vessel cubic meter LNG tank. The liqui? ed grid to recharge the battery pack. All also features Z-drive propul-

Natural Gas fuels the 4,800 kW main. of these power sources, combined with sion and 400 hp bow thrusters,

Making an innovative green vessel the SCR after treatment of the Cummins allowing it to move smoothly is more complex than a simple change QSK60 auxiliary engine, makes for a in tight areas. The Aurora/Qa- of fuel for the main engine. To further notably green ship.

mun meets Ice Class and Polar protect the environment, the vessel is The electrical systems is integrated in

Code requirements, which in- designed to minimize energy use. The such a manner that the vessel will dem- clude increased structural fram-

LNG is stored at -140 to -160 degrees onstrate an overall reduction of green- ing, shell plating, and extended

Celsius so must be heated for use by the house gas emissions by as much as 42%. zero-discharge endurance with shallow water capability. More details are available on this speci? cations sheet.

Master Boat Builders built the tug, with the barge built by

Gunderson Marine LLC.

Crowley operates and man- ages 42 Jones Act quali? ed large petroleum transportation vessels that carried nearly 570 million barrels of product with more than 5,700 transfers in 2020.

Photo courtesy Skipsteknisk and Selvåg AS 42 Maritime Reporter & Engineering News • August 2021

MR #8 (34-49).indd 42 8/3/2021 3:35:24 PM

41

41

43

43