Page 52: of Maritime Reporter Magazine (August 2021)

The Shipyard Annual

Read this page in Pdf, Flash or Html5 edition of August 2021 Maritime Reporter Magazine

TECH FEATURE CORROSION 12

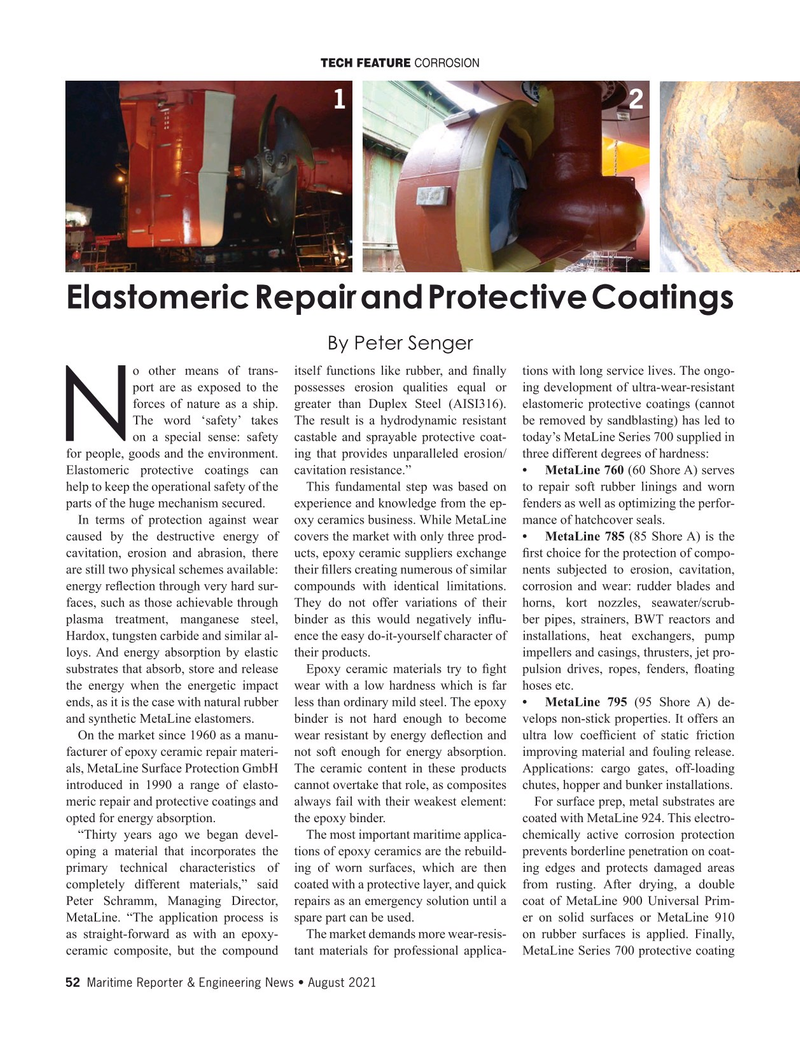

Elastomeric Repair and Protective Coatings

By Peter Senger o other means of trans- itself functions like rubber, and ? nally tions with long service lives. The ongo- port are as exposed to the possesses erosion qualities equal or ing development of ultra-wear-resistant forces of nature as a ship. greater than Duplex Steel (AISI316). elastomeric protective coatings (cannot

The word ‘safety’ takes The result is a hydrodynamic resistant be removed by sandblasting) has led to on a special sense: safety castable and sprayable protective coat- today’s MetaLine Series 700 supplied in

N for people, goods and the environment. ing that provides unparalleled erosion/ three different degrees of hardness:

Elastomeric protective coatings can cavitation resistance.” • MetaLine 760 (60 Shore A) serves help to keep the operational safety of the This fundamental step was based on to repair soft rubber linings and worn parts of the huge mechanism secured. experience and knowledge from the ep- fenders as well as optimizing the perfor-

In terms of protection against wear oxy ceramics business. While MetaLine mance of hatchcover seals.

caused by the destructive energy of covers the market with only three prod- • MetaLine 785 (85 Shore A) is the cavitation, erosion and abrasion, there ucts, epoxy ceramic suppliers exchange ? rst choice for the protection of compo- are still two physical schemes available: their ? llers creating numerous of similar nents subjected to erosion, cavitation, energy re? ection through very hard sur- compounds with identical limitations. corrosion and wear: rudder blades and faces, such as those achievable through They do not offer variations of their horns, kort nozzles, seawater/scrub- plasma treatment, manganese steel, binder as this would negatively in? u- ber pipes, strainers, BWT reactors and

Hardox, tungsten carbide and similar al- ence the easy do-it-yourself character of installations, heat exchangers, pump loys. And energy absorption by elastic their products. impellers and casings, thrusters, jet pro- substrates that absorb, store and release Epoxy ceramic materials try to ? ght pulsion drives, ropes, fenders, ? oating the energy when the energetic impact wear with a low hardness which is far hoses etc.

ends, as it is the case with natural rubber less than ordinary mild steel. The epoxy • MetaLine 795 (95 Shore A) de- and synthetic MetaLine elastomers. binder is not hard enough to become velops non-stick properties. It offers an

On the market since 1960 as a manu- wear resistant by energy de? ection and ultra low coef? cient of static friction facturer of epoxy ceramic repair materi- not soft enough for energy absorption. improving material and fouling release. als, MetaLine Surface Protection GmbH The ceramic content in these products Applications: cargo gates, off-loading introduced in 1990 a range of elasto- cannot overtake that role, as composites chutes, hopper and bunker installations.

meric repair and protective coatings and always fail with their weakest element: For surface prep, metal substrates are opted for energy absorption. the epoxy binder. coated with MetaLine 924. This electro- “Thirty years ago we began devel- The most important maritime applica- chemically active corrosion protection oping a material that incorporates the tions of epoxy ceramics are the rebuild- prevents borderline penetration on coat- primary technical characteristics of ing of worn surfaces, which are then ing edges and protects damaged areas completely different materials,” said coated with a protective layer, and quick from rusting. After drying, a double

Peter Schramm, Managing Director, repairs as an emergency solution until a coat of MetaLine 900 Universal Prim-

MetaLine. “The application process is spare part can be used. er on solid surfaces or MetaLine 910 as straight-forward as with an epoxy- The market demands more wear-resis- on rubber surfaces is applied. Finally, ceramic composite, but the compound tant materials for professional applica- MetaLine Series 700 protective coating 52 Maritime Reporter & Engineering News • August 2021

MR #8 (50-58).indd 52 8/3/2021 3:18:06 PM

51

51

53

53