Page 21: of Maritime Reporter Magazine (December 2021)

Great Ships of 2021 Edition

Read this page in Pdf, Flash or Html5 edition of December 2021 Maritime Reporter Magazine

OFFSHORE WIND FLOATING WIND ing foundations,” says Aker Solutions’ SVP for Offshore helps reduce reliance on what’s currently a very limited mar-

Wind, Kenneth Simonsen. “If we’re having something that’s ket for Jones Act-compliant installation vessels, it constrains 80m x 80m, almost like a football ? eld, and you want to build activity to ports where there’s suf? cient air draft, points out 50, that’s a lot of acreage you will need. So we need new solu- Lanard – so no overhead transmission wires or bridges, as tions for that construction and the whole logistics around it well as suf? cient water depth. and I don’t think we’ve seen the optimum solutions around For all types of ? oater, onshore assembly then complete this yet. That’s something we’re wrestling with today.” turbine tow-out to site is seen as the predominant construc-

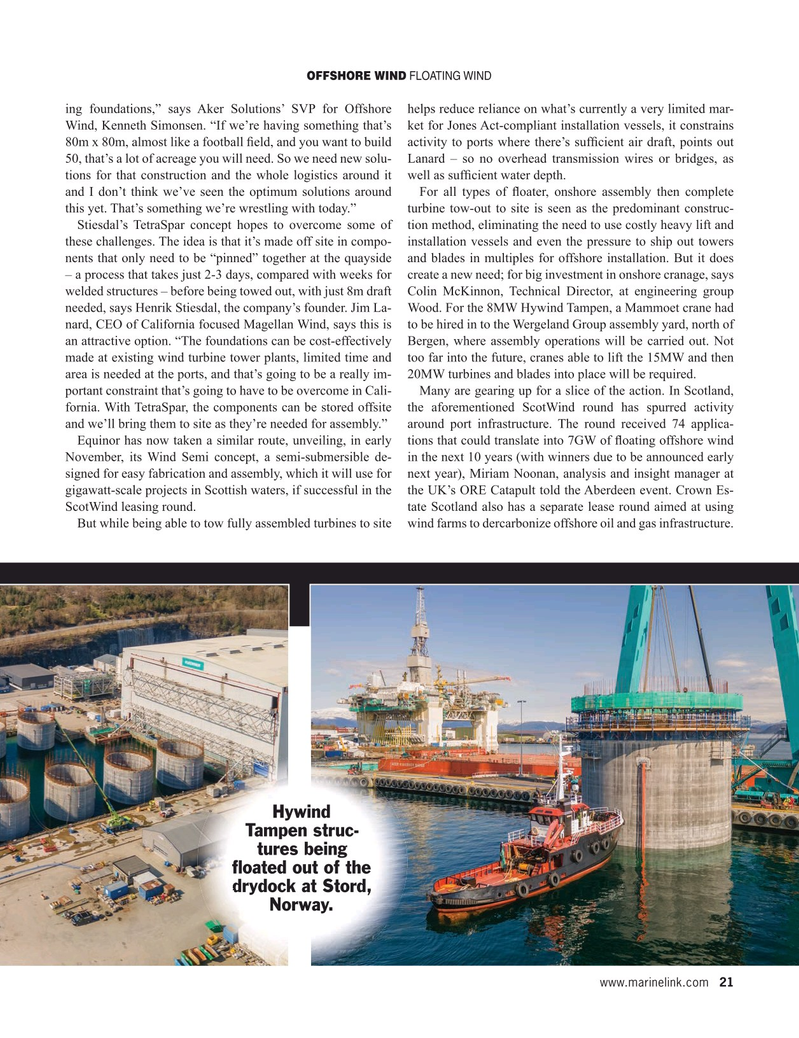

Stiesdal’s TetraSpar concept hopes to overcome some of tion method, eliminating the need to use costly heavy lift and these challenges. The idea is that it’s made off site in compo- installation vessels and even the pressure to ship out towers nents that only need to be “pinned” together at the quayside and blades in multiples for offshore installation. But it does – a process that takes just 2-3 days, compared with weeks for create a new need; for big investment in onshore cranage, says welded structures – before being towed out, with just 8m draft Colin McKinnon, Technical Director, at engineering group needed, says Henrik Stiesdal, the company’s founder. Jim La- Wood. For the 8MW Hywind Tampen, a Mammoet crane had nard, CEO of California focused Magellan Wind, says this is to be hired in to the Wergeland Group assembly yard, north of an attractive option. “The foundations can be cost-effectively Bergen, where assembly operations will be carried out. Not made at existing wind turbine tower plants, limited time and too far into the future, cranes able to lift the 15MW and then area is needed at the ports, and that’s going to be a really im- 20MW turbines and blades into place will be required. portant constraint that’s going to have to be overcome in Cali- Many are gearing up for a slice of the action. In Scotland, fornia. With TetraSpar, the components can be stored offsite the aforementioned ScotWind round has spurred activity and we’ll bring them to site as they’re needed for assembly.” around port infrastructure. The round received 74 applica-

Equinor has now taken a similar route, unveiling, in early tions that could translate into 7GW of ? oating offshore wind

November, its Wind Semi concept, a semi-submersible de- in the next 10 years (with winners due to be announced early signed for easy fabrication and assembly, which it will use for next year), Miriam Noonan, analysis and insight manager at gigawatt-scale projects in Scottish waters, if successful in the the UK’s ORE Catapult told the Aberdeen event. Crown Es-

ScotWind leasing round. tate Scotland also has a separate lease round aimed at using

But while being able to tow fully assembled turbines to site wind farms to dercarbonize offshore oil and gas infrastructure.

Hy ywii y nd en Tampe struc- tures b b e being ou u ? oated ut of the d drydock k a at k t Stord, ,

No orw w o way.

www.marinelink.com 21

MR #12 (18-33).indd 21 12/2/2021 10:50:16 AM

20

20

22

22