Page 35: of Maritime Reporter Magazine (December 2021)

Great Ships of 2021 Edition

Read this page in Pdf, Flash or Html5 edition of December 2021 Maritime Reporter Magazine

GREAT SHIPS of the future?

• AIP: Aquaculture Superyacht • • HPB-1900 •

Photo courtesy RINA

Photo courtesy BMT • Ocean Plastic Harvester • • North Star Renewable SOV •

Photo courtesy Our Cleaner Planet

Photo courtesy North Star Renewables

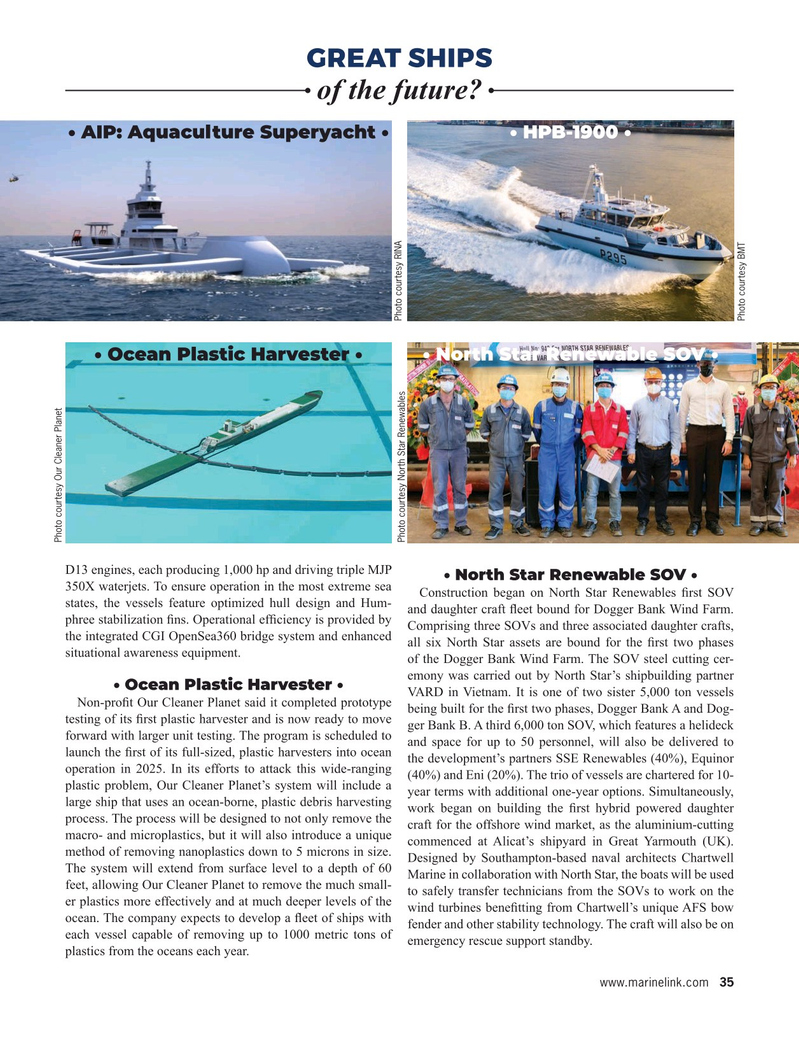

D13 engines, each producing 1,000 hp and driving triple MJP • North Star Renewable SOV • 350X waterjets. To ensure operation in the most extreme sea

Construction began on North Star Renewables ? rst SOV states, the vessels feature optimized hull design and Hum- and daughter craft ? eet bound for Dogger Bank Wind Farm. phree stabilization ? ns. Operational ef? ciency is provided by

Comprising three SOVs and three associated daughter crafts, the integrated CGI OpenSea360 bridge system and enhanced all six North Star assets are bound for the ? rst two phases situational awareness equipment.

of the Dogger Bank Wind Farm. The SOV steel cutting cer- emony was carried out by North Star’s shipbuilding partner • Ocean Plastic Harvester •

VARD in Vietnam. It is one of two sister 5,000 ton vessels

Non-pro? t Our Cleaner Planet said it completed prototype being built for the ? rst two phases, Dogger Bank A and Dog- testing of its ? rst plastic harvester and is now ready to move ger Bank B. A third 6,000 ton SOV, which features a helideck forward with larger unit testing. The program is scheduled to and space for up to 50 personnel, will also be delivered to launch the ? rst of its full-sized, plastic harvesters into ocean the development’s partners SSE Renewables (40%), Equinor operation in 2025. In its efforts to attack this wide-ranging (40%) and Eni (20%). The trio of vessels are chartered for 10- plastic problem, Our Cleaner Planet’s system will include a year terms with additional one-year options. Simultaneously, large ship that uses an ocean-borne, plastic debris harvesting work began on building the ? rst hybrid powered daughter process. The process will be designed to not only remove the craft for the offshore wind market, as the aluminium-cutting macro- and microplastics, but it will also introduce a unique commenced at Alicat’s shipyard in Great Yarmouth (UK). method of removing nanoplastics down to 5 microns in size.

Designed by Southampton-based naval architects Chartwell

The system will extend from surface level to a depth of 60 Marine in collaboration with North Star, the boats will be used feet, allowing Our Cleaner Planet to remove the much small- to safely transfer technicians from the SOVs to work on the er plastics more effectively and at much deeper levels of the wind turbines bene? tting from Chartwell’s unique AFS bow ocean. The company expects to develop a ? eet of ships with fender and other stability technology. The craft will also be on each vessel capable of removing up to 1000 metric tons of emergency rescue support standby. plastics from the oceans each year.

www.marinelink.com 35

MR #12 (34-43).indd 35 12/2/2021 9:47:11 AM

34

34

36

36