Page 14: of Maritime Reporter Magazine (January 2022)

The Ship Repair & Conversion Edition

Read this page in Pdf, Flash or Html5 edition of January 2022 Maritime Reporter Magazine

Back to the Drawing Board

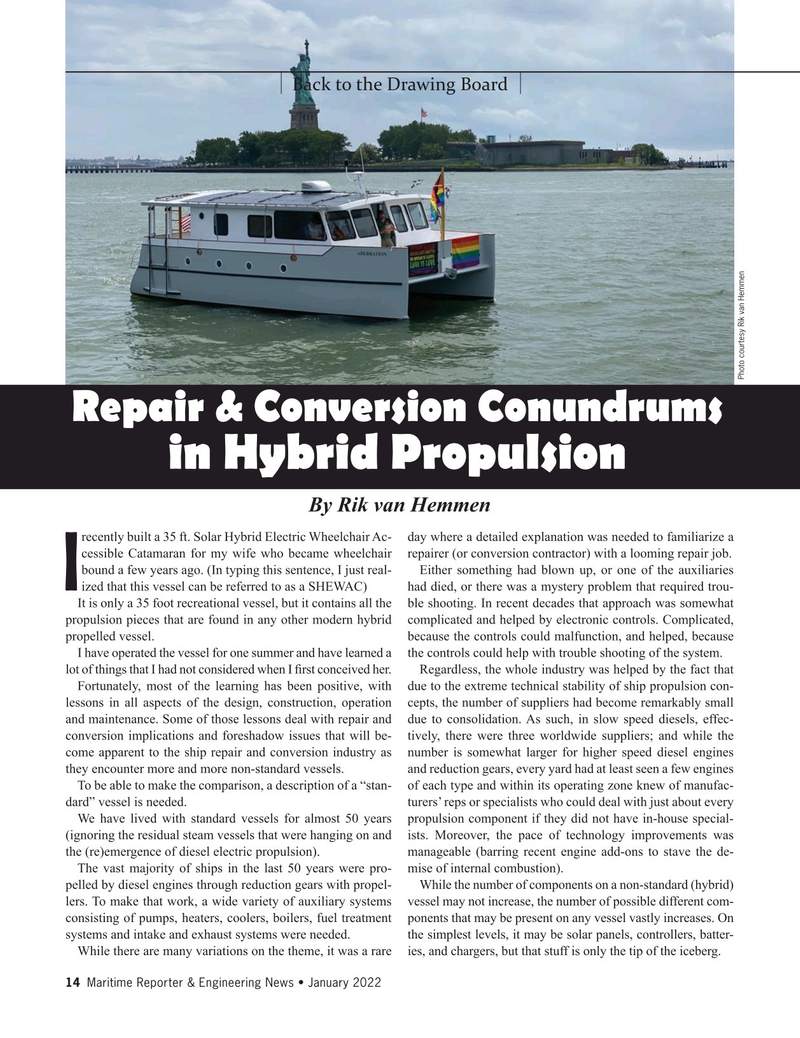

Photo courtesy Rik van Hemmen

Repair & Conversion Conundrums in Hybrid Propulsion

By Rik van Hemmen recently built a 35 ft. Solar Hybrid Electric Wheelchair Ac- day where a detailed explanation was needed to familiarize a cessible Catamaran for my wife who became wheelchair repairer (or conversion contractor) with a looming repair job.

bound a few years ago. (In typing this sentence, I just real- Either something had blown up, or one of the auxiliaries

I ized that this vessel can be referred to as a SHEWAC) had died, or there was a mystery problem that required trou-

It is only a 35 foot recreational vessel, but it contains all the ble shooting. In recent decades that approach was somewhat propulsion pieces that are found in any other modern hybrid complicated and helped by electronic controls. Complicated, propelled vessel. because the controls could malfunction, and helped, because

I have operated the vessel for one summer and have learned a the controls could help with trouble shooting of the system.

lot of things that I had not considered when I ? rst conceived her. Regardless, the whole industry was helped by the fact that

Fortunately, most of the learning has been positive, with due to the extreme technical stability of ship propulsion con- lessons in all aspects of the design, construction, operation cepts, the number of suppliers had become remarkably small and maintenance. Some of those lessons deal with repair and due to consolidation. As such, in slow speed diesels, effec- conversion implications and foreshadow issues that will be- tively, there were three worldwide suppliers; and while the come apparent to the ship repair and conversion industry as number is somewhat larger for higher speed diesel engines they encounter more and more non-standard vessels. and reduction gears, every yard had at least seen a few engines

To be able to make the comparison, a description of a “stan- of each type and within its operating zone knew of manufac- dard” vessel is needed. turers’ reps or specialists who could deal with just about every

We have lived with standard vessels for almost 50 years propulsion component if they did not have in-house special- (ignoring the residual steam vessels that were hanging on and ists. Moreover, the pace of technology improvements was the (re)emergence of diesel electric propulsion). manageable (barring recent engine add-ons to stave the de-

The vast majority of ships in the last 50 years were pro- mise of internal combustion).

pelled by diesel engines through reduction gears with propel- While the number of components on a non-standard (hybrid) lers. To make that work, a wide variety of auxiliary systems vessel may not increase, the number of possible different com- consisting of pumps, heaters, coolers, boilers, fuel treatment ponents that may be present on any vessel vastly increases. On systems and intake and exhaust systems were needed. the simplest levels, it may be solar panels, controllers, batter-

While there are many variations on the theme, it was a rare ies, and chargers, but that stuff is only the tip of the iceberg.

14 Maritime Reporter & Engineering News • January 2022

MR #1 (1-17).indd 14 1/6/2022 9:46:40 AM

13

13

15

15