Page 58: of Maritime Reporter Magazine (April 2022)

Offshore Energy

Read this page in Pdf, Flash or Html5 edition of April 2022 Maritime Reporter Magazine

In the Shipyard

Latest Deliveries, Contracts and Designs

Image courtesy NYK, MTI, Elomatic Oy

ARLFV

NYK, MTI and Elomatic completed the development of a concept design for an ammonia-fuel ready LNG- fueled vessel (ARLFV). In this project, which started in

September 2021, NYK Group

Photo courtesy RINA/FKAP and Elomatic started the development of a concept design for an ARLFV that

Tanker Concept Exceeds ’50 can ef? ciently be converted from an LNG-fueled vessel to

Targets Using Fossil Fuels an ammonia-fueled vessel, based on the assumption

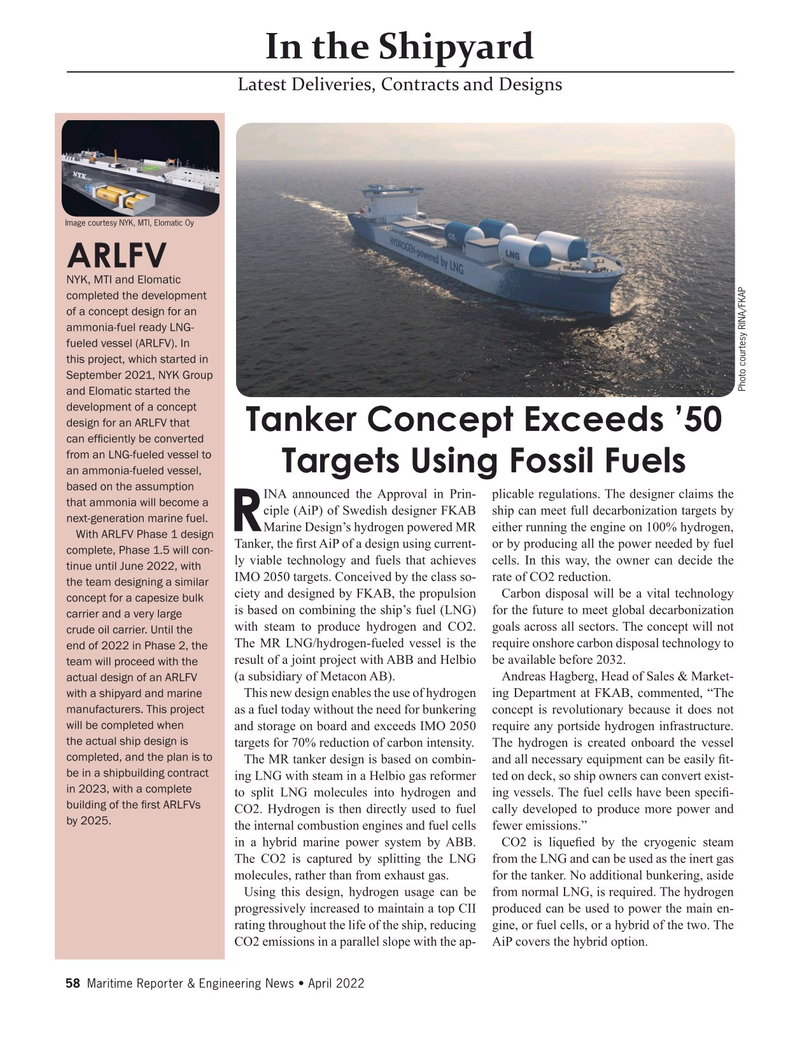

INA announced the Approval in Prin- plicable regulations. The designer claims the that ammonia will become a ciple (AiP) of Swedish designer FKAB ship can meet full decarbonization targets by next-generation marine fuel.

RMarine Design’s hydrogen powered MR either running the engine on 100% hydrogen,

With ARLFV Phase 1 design

Tanker, the ? rst AiP of a design using current- or by producing all the power needed by fuel complete, Phase 1.5 will con- ly viable technology and fuels that achieves cells. In this way, the owner can decide the tinue until June 2022, with

IMO 2050 targets. Conceived by the class so- rate of CO2 reduction.

the team designing a similar ciety and designed by FKAB, the propulsion Carbon disposal will be a vital technology concept for a capesize bulk is based on combining the ship’s fuel (LNG) for the future to meet global decarbonization carrier and a very large with steam to produce hydrogen and CO2. goals across all sectors. The concept will not crude oil carrier. Until the

The MR LNG/hydrogen-fueled vessel is the require onshore carbon disposal technology to end of 2022 in Phase 2, the result of a joint project with ABB and Helbio be available before 2032. team will proceed with the (a subsidiary of Metacon AB). Andreas Hagberg, Head of Sales & Market- actual design of an ARLFV

This new design enables the use of hydrogen ing Department at FKAB, commented, “The with a shipyard and marine manufacturers. This project as a fuel today without the need for bunkering concept is revolutionary because it does not will be completed when and storage on board and exceeds IMO 2050 require any portside hydrogen infrastructure. the actual ship design is targets for 70% reduction of carbon intensity. The hydrogen is created onboard the vessel completed, and the plan is to

The MR tanker design is based on combin- and all necessary equipment can be easily ? t- be in a shipbuilding contract ing LNG with steam in a Helbio gas reformer ted on deck, so ship owners can convert exist- in 2023, with a complete to split LNG molecules into hydrogen and ing vessels. The fuel cells have been speci? - building of the ? rst ARLFVs

CO2. Hydrogen is then directly used to fuel cally developed to produce more power and by 2025.

the internal combustion engines and fuel cells fewer emissions.” in a hybrid marine power system by ABB. CO2 is lique? ed by the cryogenic steam

The CO2 is captured by splitting the LNG from the LNG and can be used as the inert gas molecules, rather than from exhaust gas. for the tanker. No additional bunkering, aside

Using this design, hydrogen usage can be from normal LNG, is required. The hydrogen progressively increased to maintain a top CII produced can be used to power the main en- rating throughout the life of the ship, reducing gine, or fuel cells, or a hybrid of the two. The

CO2 emissions in a parallel slope with the ap- AiP covers the hybrid option.

58 Maritime Reporter & Engineering News • April 2022

MR #4 (50-58).indd 58 4/5/2022 3:11:41 PM

57

57

59

59