Page 55: of Maritime Reporter Magazine (June 2022)

USCG Fleet Modernization Annual

Read this page in Pdf, Flash or Html5 edition of June 2022 Maritime Reporter Magazine

In the Shipyard

Latest Deliveries, Contracts and Designs

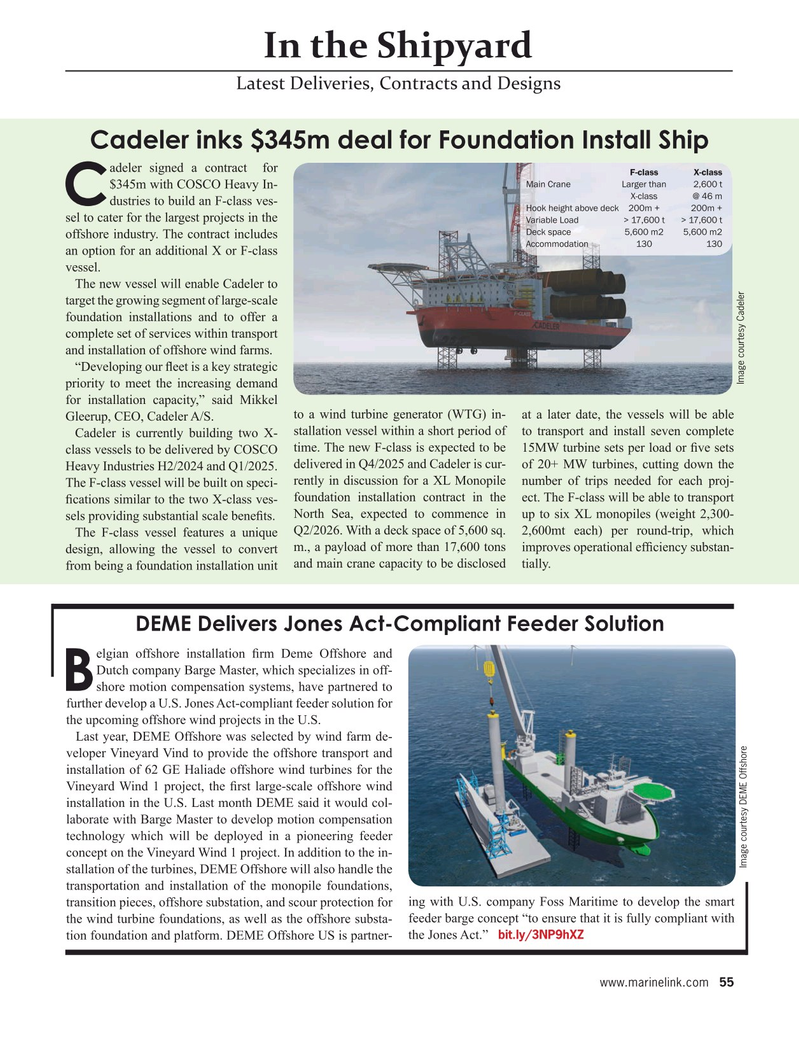

Cadeler inks $345m deal for Foundation Install Ship adeler signed a contract for F-class X-class

Main Crane Larger than 2,600 t $345m with COSCO Heavy In- X-class @ 46 m dustries to build an F-class ves-

C

Hook height above deck 200m + 200m + sel to cater for the largest projects in the

Variable Load > 17,600 t > 17,600 t

Deck space 5,600 m2 5,600 m2 offshore industry. The contract includes

Accommodation 130 130 an option for an additional X or F-class vessel.

The new vessel will enable Cadeler to target the growing segment of large-scale foundation installations and to offer a complete set of services within transport and installation of offshore wind farms.

“Developing our ? eet is a key strategic

Image courtesy Cadeler priority to meet the increasing demand for installation capacity,” said Mikkel to a wind turbine generator (WTG) in- at a later date, the vessels will be able

Gleerup, CEO, Cadeler A/S. stallation vessel within a short period of to transport and install seven complete

Cadeler is currently building two X- class vessels to be delivered by COSCO time. The new F-class is expected to be 15MW turbine sets per load or ? ve sets

Heavy Industries H2/2024 and Q1/2025. delivered in Q4/2025 and Cadeler is cur- of 20+ MW turbines, cutting down the rently in discussion for a XL Monopile number of trips needed for each proj-

The F-class vessel will be built on speci- foundation installation contract in the ect. The F-class will be able to transport ? cations similar to the two X-class ves-

North Sea, expected to commence in up to six XL monopiles (weight 2,300- sels providing substantial scale bene? ts.

The F-class vessel features a unique Q2/2026. With a deck space of 5,600 sq. 2,600mt each) per round-trip, which design, allowing the vessel to convert m., a payload of more than 17,600 tons improves operational ef? ciency substan- from being a foundation installation unit and main crane capacity to be disclosed tially.

DEME Delivers Jones Act-Compliant Feeder Solution elgian offshore installation ? rm Deme Offshore and

Dutch company Barge Master, which specializes in off-

B shore motion compensation systems, have partnered to further develop a U.S. Jones Act-compliant feeder solution for the upcoming offshore wind projects in the U.S.

Last year, DEME Offshore was selected by wind farm de- veloper Vineyard Vind to provide the offshore transport and installation of 62 GE Haliade offshore wind turbines for the

Vineyard Wind 1 project, the ? rst large-scale offshore wind installation in the U.S. Last month DEME said it would col- laborate with Barge Master to develop motion compensation technology which will be deployed in a pioneering feeder concept on the Vineyard Wind 1 project. In addition to the in-

Image courtesy DEME Offshore stallation of the turbines, DEME Offshore will also handle the transportation and installation of the monopile foundations, transition pieces, offshore substation, and scour protection for ing with U.S. company Foss Maritime to develop the smart the wind turbine foundations, as well as the offshore substa- feeder barge concept “to ensure that it is fully compliant with bit.ly/3NP9hXZ tion foundation and platform. DEME Offshore US is partner- the Jones Act.” www.marinelink.com 55

MR #6 (50-59).indd 55 6/6/2022 9:33:51 AM

54

54

56

56