Page 54: of Maritime Reporter Magazine (August 2022)

The Shipyard Annual

Read this page in Pdf, Flash or Html5 edition of August 2022 Maritime Reporter Magazine

TECH FEATURE THORDON BEARINGS

WATER LUBRICATED BEARINGS

ENABLE THE “STERNTUBE-LESS SHIP”

With the advance of seawater-lubricated polymer-based propeller shaft bearing, the traditional role of the sterntube is revisited.

By Pat Wheater surveyors can gain access for shaft inspec- tions by entering the Thomson SternSpace and a lot of the shaft installation and oper- ational challenges completely disappear.”

Thordon and ABS estimate that, in a case of an aftmost bearing replacement due to damage or complete failure, a two- week re-alignment job that is estimated to cost more than $100,000 in drydock and labor fees can be done in a single day a? oat. When you take the zero lubri- cating oil requirement into account, the overall OPEX savings are signi? cant.

he sealed sterntube has long been the stern in anyway), which in a tradi- “We moved the engine further aft, an essential component to ships tional powertrain has a crankshaft driv- making the shaftline shorter so that we at sea, the aft seal providing pro- ing a long shaftline, with the sterntube didn’t need a forward sterntube bearing

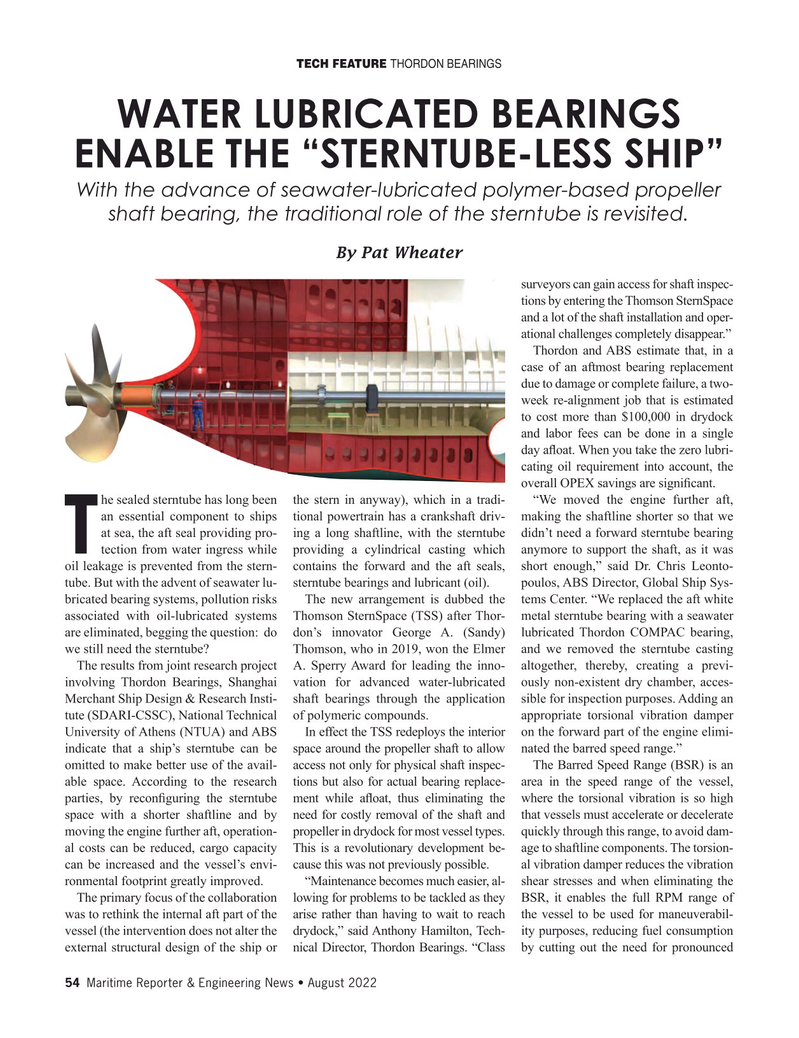

T tection from water ingress while providing a cylindrical casting which anymore to support the shaft, as it was oil leakage is prevented from the stern- contains the forward and the aft seals, short enough,” said Dr. Chris Leonto- tube. But with the advent of seawater lu- sterntube bearings and lubricant (oil). poulos, ABS Director, Global Ship Sys- bricated bearing systems, pollution risks The new arrangement is dubbed the tems Center. “We replaced the aft white associated with oil-lubricated systems Thomson SternSpace (TSS) after Thor- metal sterntube bearing with a seawater are eliminated, begging the question: do don’s innovator George A. (Sandy) lubricated Thordon COMPAC bearing, we still need the sterntube? Thomson, who in 2019, won the Elmer and we removed the sterntube casting

The results from joint research project A. Sperry Award for leading the inno- altogether, thereby, creating a previ- involving Thordon Bearings, Shanghai vation for advanced water-lubricated ously non-existent dry chamber, acces-

Merchant Ship Design & Research Insti- shaft bearings through the application sible for inspection purposes. Adding an tute (SDARI-CSSC), National Technical of polymeric compounds. appropriate torsional vibration damper

University of Athens (NTUA) and ABS In effect the TSS redeploys the interior on the forward part of the engine elimi- indicate that a ship’s sterntube can be space around the propeller shaft to allow nated the barred speed range.” omitted to make better use of the avail- access not only for physical shaft inspec- The Barred Speed Range (BSR) is an able space. According to the research tions but also for actual bearing replace- area in the speed range of the vessel, parties, by recon? guring the sterntube ment while a? oat, thus eliminating the where the torsional vibration is so high space with a shorter shaftline and by need for costly removal of the shaft and that vessels must accelerate or decelerate moving the engine further aft, operation- propeller in drydock for most vessel types. quickly through this range, to avoid dam- al costs can be reduced, cargo capacity This is a revolutionary development be- age to shaftline components. The torsion- can be increased and the vessel’s envi- cause this was not previously possible. al vibration damper reduces the vibration ronmental footprint greatly improved. “Maintenance becomes much easier, al- shear stresses and when eliminating the

The primary focus of the collaboration lowing for problems to be tackled as they BSR, it enables the full RPM range of was to rethink the internal aft part of the arise rather than having to wait to reach the vessel to be used for maneuverabil- vessel (the intervention does not alter the drydock,” said Anthony Hamilton, Tech- ity purposes, reducing fuel consumption external structural design of the ship or nical Director, Thordon Bearings. “Class by cutting out the need for pronounced 54 Maritime Reporter & Engineering News • August 2022

MR #8 (50-59).indd 54 8/4/2022 9:04:31 AM

53

53

55

55