Page 12: of Maritime Reporter Magazine (January 2023)

The Ship Repair & Conversion Edition

Read this page in Pdf, Flash or Html5 edition of January 2023 Maritime Reporter Magazine

Eye on the Navy

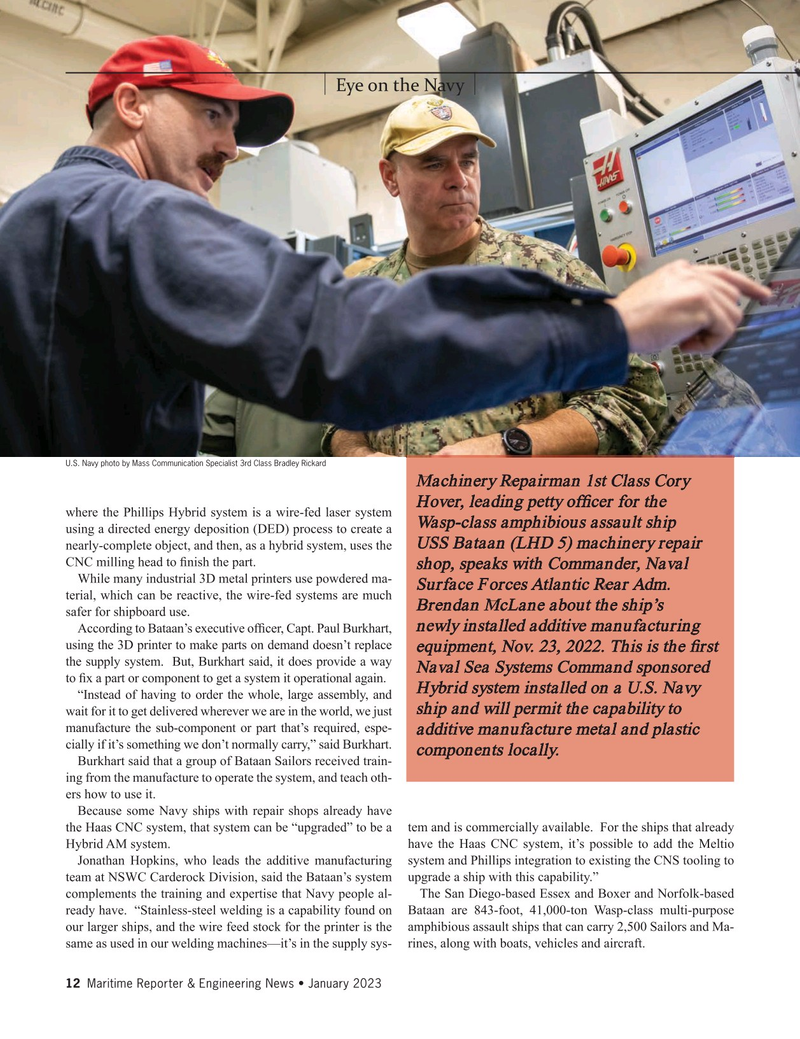

U.S. Navy photo by Mass Communication Specialist 3rd Class Bradley Rickard

Machinery Repairman 1st Class Cory

Hover, leading petty of? cer for the where the Phillips Hybrid system is a wire-fed laser system

Wasp-class amphibious assault ship using a directed energy deposition (DED) process to create a

USS Bataan (LHD 5) machinery repair nearly-complete object, and then, as a hybrid system, uses the

CNC milling head to ? nish the part.

shop, speaks with Commander, Naval

While many industrial 3D metal printers use powdered ma-

Surface Forces Atlantic Rear Adm. terial, which can be reactive, the wire-fed systems are much

Brendan McLane about the ship’s safer for shipboard use.

newly installed additive manufacturing

According to Bataan’s executive of? cer, Capt. Paul Burkhart, using the 3D printer to make parts on demand doesn’t replace equipment, Nov. 23, 2022. This is the ? rst the supply system. But, Burkhart said, it does provide a way

Naval Sea Systems Command sponsored to ? x a part or component to get a system it operational again.

Hybrid system installed on a U.S. Navy “Instead of having to order the whole, large assembly, and ship and will permit the capability to wait for it to get delivered wherever we are in the world, we just manufacture the sub-component or part that’s required, espe- additive manufacture metal and plastic cially if it’s something we don’t normally carry,” said Burkhart.

components locally.

Burkhart said that a group of Bataan Sailors received train- ing from the manufacture to operate the system, and teach oth- ers how to use it.

Because some Navy ships with repair shops already have the Haas CNC system, that system can be “upgraded” to be a tem and is commercially available. For the ships that already

Hybrid AM system. have the Haas CNC system, it’s possible to add the Meltio

Jonathan Hopkins, who leads the additive manufacturing system and Phillips integration to existing the CNS tooling to team at NSWC Carderock Division, said the Bataan’s system upgrade a ship with this capability.” complements the training and expertise that Navy people al- The San Diego-based Essex and Boxer and Norfolk-based ready have. “Stainless-steel welding is a capability found on Bataan are 843-foot, 41,000-ton Wasp-class multi-purpose our larger ships, and the wire feed stock for the printer is the amphibious assault ships that can carry 2,500 Sailors and Ma- same as used in our welding machines—it’s in the supply sys- rines, along with boats, vehicles and aircraft.

12 Maritime Reporter & Engineering News • January 2023

MR #1 (1-17).indd 12 1/5/2023 6:26:54 PM

11

11

13

13