Page 22: of Maritime Reporter Magazine (January 2023)

The Ship Repair & Conversion Edition

Read this page in Pdf, Flash or Html5 edition of January 2023 Maritime Reporter Magazine

MARINE POWER & FUELS of ammonia; plan B is aftertreatment. the tanks, because ammonia will be expensive.”

According to Foldager and Chatterjee, engine optimization According to the International Energy Agency (IEA), about and tuning will be paramount to keep in check one of the most 180 million metric tons of ammonia is produced annually, harmful remnants of burning ammonia as fuel: nitrous oxide with production expected to rise nearly 40% to 250 million (N O), which is a more harmful greenhouse gas than carbon metric tons by 2050. Today, China is the largest producer of 2 dioxide. The current plan is use SCR aftertreament to clean ammonia (30% of the production volume generating 45% of capture N O, ammonia slip and NOx, too. the associated CO2 emissions), with the United States, the Eu- 2

In step with effective combustion, Foldager said overall en- ropean Union, India, Russia and the Middle East accounting gine reliability is paramount. “It has to be reliable. There’s for a further 8-10% each. It is traded globally, with exports via only one engine in the ship, it’s the heart of the ship, it has to ship equating to about 10% of total production. run 24/7. Third, we have to make sure that the emissions are The ? ip side of ammonia is, today, it relies heavily on fos- acceptable.” sil fuels for its production, and hence emission intensive, too.

As designed, “the ammonia is in single wall pipes, but as Long-term, a ramp-up in ‘green ammonia’ is needed. Another soon it gets into the engine room, it will go in double wall disadvantage to ammonia is its toxicity, and Foldager said that pipes with an inner pipe and an outer pipe,” said Foldager. even now, at the research stage, efforts to identify and mitigate “Fresh air needs to be continuously circulated through the risks, from the handling to the burning of the fuel, is central to outer pipe to detect leakage from the inner pipe. We also have it’s long-term success.

a compressor for the ventilation of the double wall pipes.” “One accidental spill on a ship could present a major set-

MAN ES has also developed its own ammonia catchment back for ammonia as a fuel and for the whole decarbonization system, “as a safety feature onboard the ship where we could of the maritime industry,” said Foldager. “So we are learning capture ammonia in the engine room if needed, or we have to a lot here and I think it’s not only about the engines, it’s about empty pipes for whatever reasons,” said Foldager. “Water will the safety of the whole system.” be a big part of it because that will absorb (the ammonia) In With roughly 18-20 million metric tons of ammonia al- this unit until we can separate water and ammonia again. The ready moving on ships in trade globally, Foldager imagines water we can reuse or pump out, the ammonia can go back to that these crews and carriers will be instrumental in helping to establish the rules regarding the safe use and handling of ammonia in the maritime sector in masse.

THE DUAL FUEL FUTURE

In planning for future maritime fuels, MAN Energy Solu- tions decided to survey it’s customers on their short-, me- dium- and long-term plans, a survey that resulted in more than 500 responses. When asked: “Which type of fuel are you planning to use for your next new-building project?” the poll found in this short- and medium-term scenario LNG/

SNG and Biogas are taking the lead, closely followed by

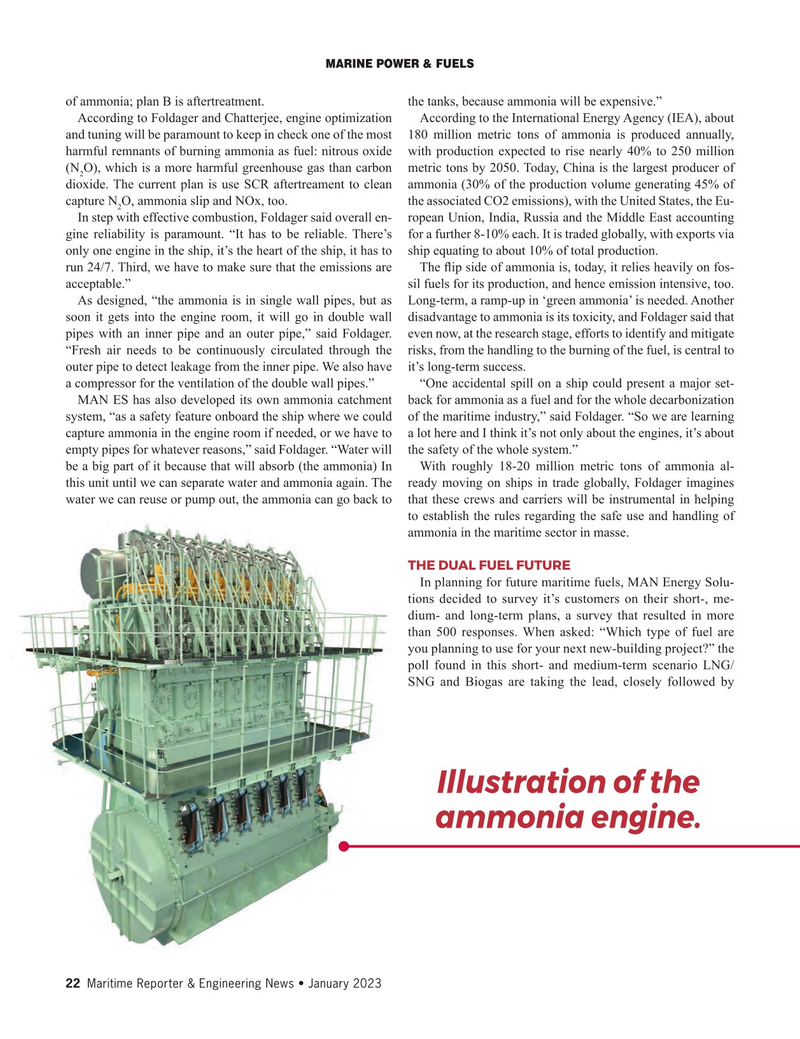

Illustration of the ammonia engine. 22 Maritime Reporter & Engineering News • January 2023

MR #1 (18-33).indd 22 1/6/2023 2:10:35 PM

21

21

23

23