Page 33: of Maritime Reporter Magazine (January 2023)

The Ship Repair & Conversion Edition

Read this page in Pdf, Flash or Html5 edition of January 2023 Maritime Reporter Magazine

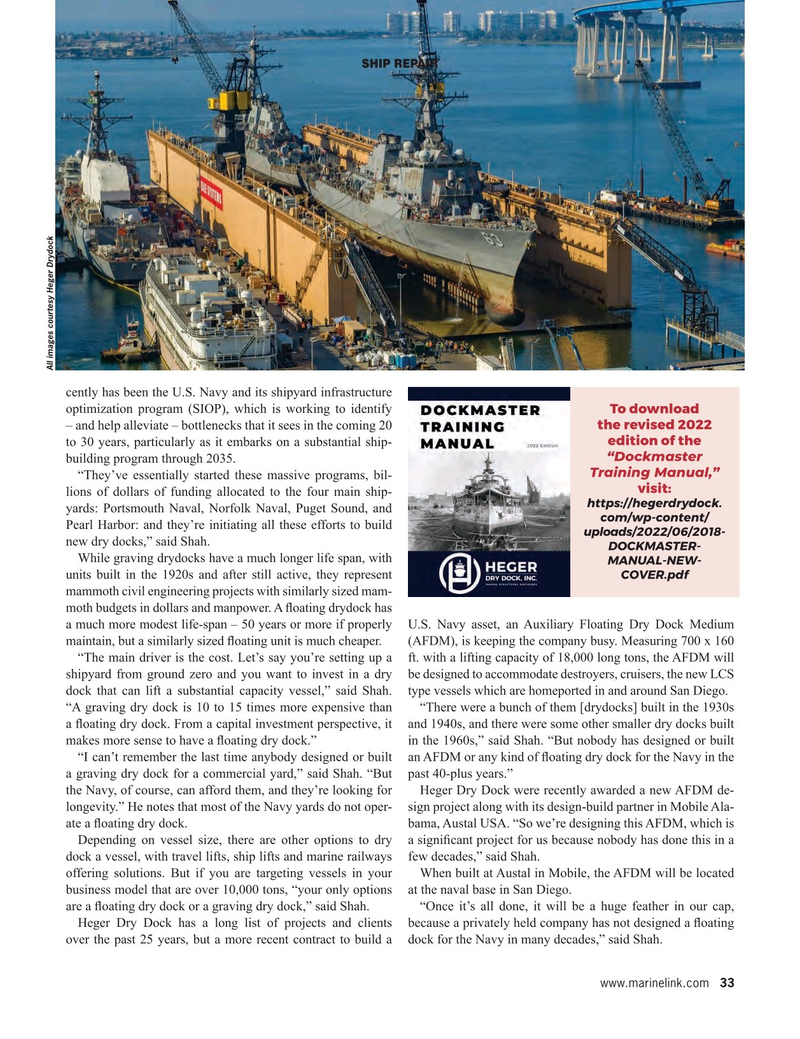

SHIP REPAIR

All images courtesy Heger Drydock cently has been the U.S. Navy and its shipyard infrastructure optimization program (SIOP), which is working to identify To download – and help alleviate – bottlenecks that it sees in the coming 20 the revised 2022 to 30 years, particularly as it embarks on a substantial ship- edition of the “Dockmaster building program through 2035.

Training Manual,” “They’ve essentially started these massive programs, bil- visit: lions of dollars of funding allocated to the four main ship- https://hegerdrydock.

yards: Portsmouth Naval, Norfolk Naval, Puget Sound, and com/wp-content/

Pearl Harbor: and they’re initiating all these efforts to build uploads/2022/06/2018- new dry docks,” said Shah.

DOCKMASTER-

While graving drydocks have a much longer life span, with

MANUAL-NEW- units built in the 1920s and after still active, they represent

COVER.pdf mammoth civil engineering projects with similarly sized mam- moth budgets in dollars and manpower. A ? oating drydock has a much more modest life-span – 50 years or more if properly U.S. Navy asset, an Auxiliary Floating Dry Dock Medium maintain, but a similarly sized ? oating unit is much cheaper. (AFDM), is keeping the company busy. Measuring 700 x 160 “The main driver is the cost. Let’s say you’re setting up a ft. with a lifting capacity of 18,000 long tons, the AFDM will shipyard from ground zero and you want to invest in a dry be designed to accommodate destroyers, cruisers, the new LCS dock that can lift a substantial capacity vessel,” said Shah. type vessels which are homeported in and around San Diego.

“A graving dry dock is 10 to 15 times more expensive than “There were a bunch of them [drydocks] built in the 1930s a ? oating dry dock. From a capital investment perspective, it and 1940s, and there were some other smaller dry docks built makes more sense to have a ? oating dry dock.” in the 1960s,” said Shah. “But nobody has designed or built “I can’t remember the last time anybody designed or built an AFDM or any kind of ? oating dry dock for the Navy in the a graving dry dock for a commercial yard,” said Shah. “But past 40-plus years.” the Navy, of course, can afford them, and they’re looking for Heger Dry Dock were recently awarded a new AFDM de- longevity.” He notes that most of the Navy yards do not oper- sign project along with its design-build partner in Mobile Ala- ate a ? oating dry dock. bama, Austal USA. “So we’re designing this AFDM, which is

Depending on vessel size, there are other options to dry a signi? cant project for us because nobody has done this in a dock a vessel, with travel lifts, ship lifts and marine railways few decades,” said Shah. offering solutions. But if you are targeting vessels in your When built at Austal in Mobile, the AFDM will be located business model that are over 10,000 tons, “your only options at the naval base in San Diego.

are a ? oating dry dock or a graving dry dock,” said Shah. “Once it’s all done, it will be a huge feather in our cap,

Heger Dry Dock has a long list of projects and clients because a privately held company has not designed a ? oating over the past 25 years, but a more recent contract to build a dock for the Navy in many decades,” said Shah.

www.marinelink.com 33

MR #1 (18-33).indd 33 1/4/2023 11:10:10 AM

32

32

34

34