Page 40: of Maritime Reporter Magazine (January 2023)

The Ship Repair & Conversion Edition

Read this page in Pdf, Flash or Html5 edition of January 2023 Maritime Reporter Magazine

SHIP REFIT BALLAST WATER MANAGEMENT SYSTEMS solution for ports unwilling to receive (port and starboard). Once at the pontoon as offering signi? cant reductions of time untreated ballast. Transfer is completed level, one pipe will lead to the forward and materials. We recently completed an simply and quickly – it is not complicat- and the other to aft injection ? ange near installation where the owners selected to ed by treatment – the barge can complete the sea chest simplifying the installation add one smaller ? lter per pump, provid- full “D2” treatment and discharge at will, process. This semi-submersible rig retro- ing greater redundancy and security of allowing the customer vessel to imme- ? t will utilize our new EcoOne Container ballasting operations, as well as reducing diately get on with its work. As owners Unit introduced in 2022 at SMM which installation footprint yet further since the begin to understand that discharge com- can be place on deck for transit only and ? lter was installed in a form of an enclo- pliance will be enforced, and as InTank removed while the rig is stationary. sure rather than full deckhouse.

continues its progress in simplifying ret- Another case was the re? t of an EcoOne Prior to the retro? t, the shipyard in- ro? ts, the operational freedom and con- Hybrid BWMS onboard a Jones-Act stalled deck mounts and any work below trol over compliance that InTank brings ATB. The EcoOne hybrid system allows the water line a year before the actual in- will be seen as increasingly valuable. for the ability to ? lter where conditions stallation because the ATB was already

As noted previously, we have already dictate, retaining the same low level of in drydock for other repairs. Through a completed retro? ts of retro? ts. InTank Cl02 dose rate of the original system. series of upfront conversations, we were is already installed from MR to VLCC, Where water conditions permit, ? lters then able to have the system installed

Handy to Cape. The new InTank FITT can be bypassed ensuring that the owner without the need to dock at all. Upon system with its easy ? lter-less installa- operator remain in control of their bal- equipment delivery, the shipyard was tions for smaller commercial vessels will lasting process at all times. able to pre-fabricate the parts and then only increase its appeal. Of additional signi? cance for the ATB lift them onboard the ATB by crane and is the modular nature of the Ecochlor mount it in situ. This shortened the over-

Marshall, Ecochlor range of systems. Installation can be en- all lead time for the installation since

I can share two! The EcoOne BWMS has tirely on deck allowing preparation of the the crew was really only focused on the many bene? ts for the offshore market. retro? t to take place well in advance of BWMS retro? t and not other drydock

For example, semi-submersibles usually the barge arriving at the shipyard. maintenance and repairs, ensuring that rely on gravity ballasting, which excludes The design and component layout of the owner had minimal valuable off-hire any BWMS requiring an inlet press (e.g., the hybrid system offer further bene? ts time.

for ? ltration). Our EcoOne system can by utilizing key attributes such as ballast use both gravity ballasting and deballast- water treatment on intake only. Thus, re- ing, which is a bene? t for Mobile Off- ducing the installation footprint as well shore Drilling Units (MODUs).

For stability reasons, semi-subs usu- ally ballast via four sea chests located

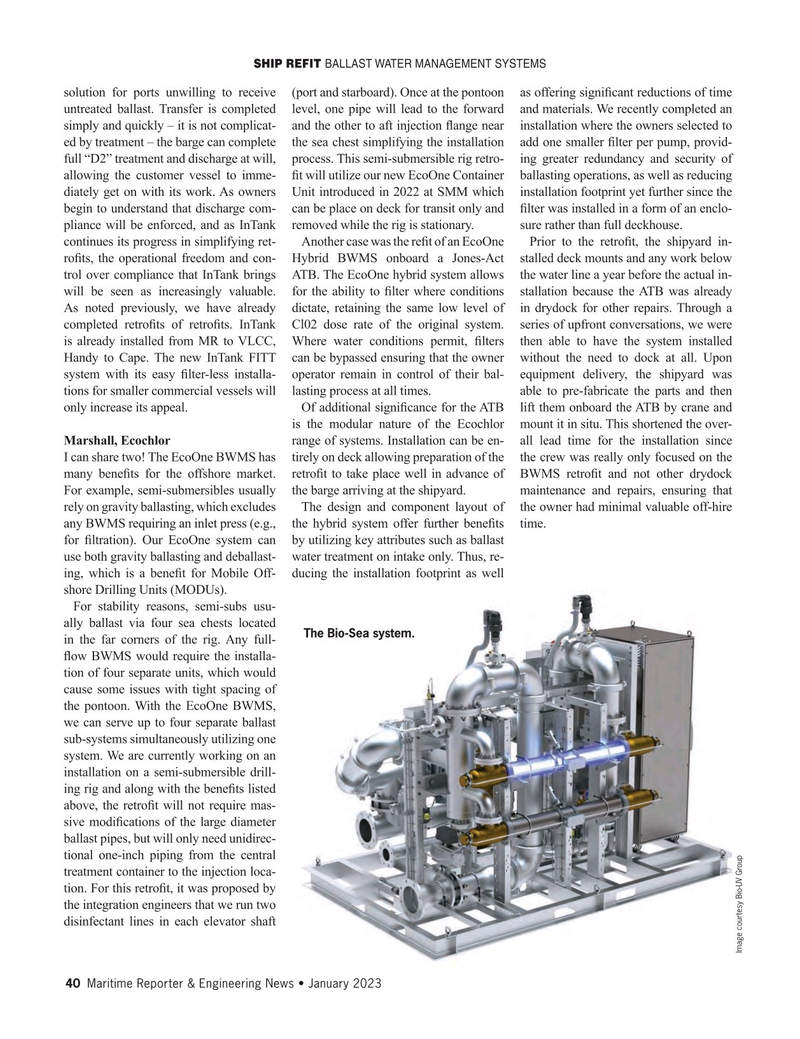

The Bio-Sea system.

in the far corners of the rig. Any full- ? ow BWMS would require the installa- tion of four separate units, which would cause some issues with tight spacing of the pontoon. With the EcoOne BWMS, we can serve up to four separate ballast sub-systems simultaneously utilizing one system. We are currently working on an installation on a semi-submersible drill- ing rig and along with the bene? ts listed above, the retro? t will not require mas- sive modi? cations of the large diameter ballast pipes, but will only need unidirec- tional one-inch piping from the central treatment container to the injection loca- tion. For this retro? t, it was proposed by the integration engineers that we run two disinfectant lines in each elevator shaft

Image courtesy Bio-UV Group 40 Maritime Reporter & Engineering News • January 2023

MR #1 (34-43).indd 40 1/5/2023 1:44:43 PM

39

39

41

41