Page 44: of Maritime Reporter Magazine (April 2023)

Cruise Shipping

Read this page in Pdf, Flash or Html5 edition of April 2023 Maritime Reporter Magazine

DECK MACHINERY

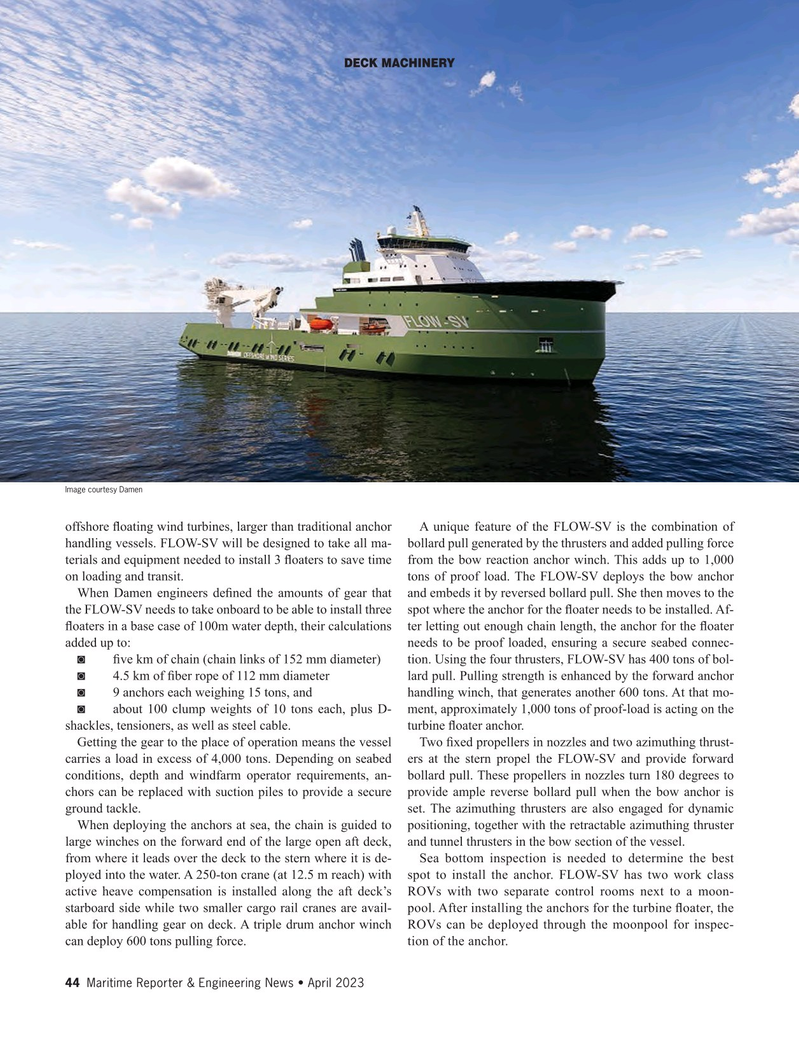

Image courtesy Damen offshore ? oating wind turbines, larger than traditional anchor A unique feature of the FLOW-SV is the combination of handling vessels. FLOW-SV will be designed to take all ma- bollard pull generated by the thrusters and added pulling force terials and equipment needed to install 3 ? oaters to save time from the bow reaction anchor winch. This adds up to 1,000 on loading and transit. tons of proof load. The FLOW-SV deploys the bow anchor

When Damen engineers de? ned the amounts of gear that and embeds it by reversed bollard pull. She then moves to the the FLOW-SV needs to take onboard to be able to install three spot where the anchor for the ? oater needs to be installed. Af- ? oaters in a base case of 100m water depth, their calculations ter letting out enough chain length, the anchor for the ? oater added up to: needs to be proof loaded, ensuring a secure seabed connec- ž ? ve km of chain (chain links of 152 mm diameter) tion. Using the four thrusters, FLOW-SV has 400 tons of bol- ž 4.5 km of ? ber rope of 112 mm diameter lard pull. Pulling strength is enhanced by the forward anchor ž 9 anchors each weighing 15 tons, and handling winch, that generates another 600 tons. At that mo- ž about 100 clump weights of 10 tons each, plus D- ment, approximately 1,000 tons of proof-load is acting on the shackles, tensioners, as well as steel cable. turbine ? oater anchor.

Getting the gear to the place of operation means the vessel Two ? xed propellers in nozzles and two azimuthing thrust- carries a load in excess of 4,000 tons. Depending on seabed ers at the stern propel the FLOW-SV and provide forward conditions, depth and windfarm operator requirements, an- bollard pull. These propellers in nozzles turn 180 degrees to chors can be replaced with suction piles to provide a secure provide ample reverse bollard pull when the bow anchor is ground tackle. set. The azimuthing thrusters are also engaged for dynamic

When deploying the anchors at sea, the chain is guided to positioning, together with the retractable azimuthing thruster large winches on the forward end of the large open aft deck, and tunnel thrusters in the bow section of the vessel. from where it leads over the deck to the stern where it is de- Sea bottom inspection is needed to determine the best ployed into the water. A 250-ton crane (at 12.5 m reach) with spot to install the anchor. FLOW-SV has two work class active heave compensation is installed along the aft deck’s ROVs with two separate control rooms next to a moon- starboard side while two smaller cargo rail cranes are avail- pool. After installing the anchors for the turbine ? oater, the able for handling gear on deck. A triple drum anchor winch ROVs can be deployed through the moonpool for inspec- can deploy 600 tons pulling force. tion of the anchor.

44 Maritime Reporter & Engineering Nes April 2023

MR #4 (34-44).indd 44 4/5/2023 7:05:00 PM

43

43

45

45