Page 55: of Maritime Reporter Magazine (August 2023)

Shipyard Annual

Read this page in Pdf, Flash or Html5 edition of August 2023 Maritime Reporter Magazine

TECH FOCUS: GREEN HYDROGEN OFFSHORE

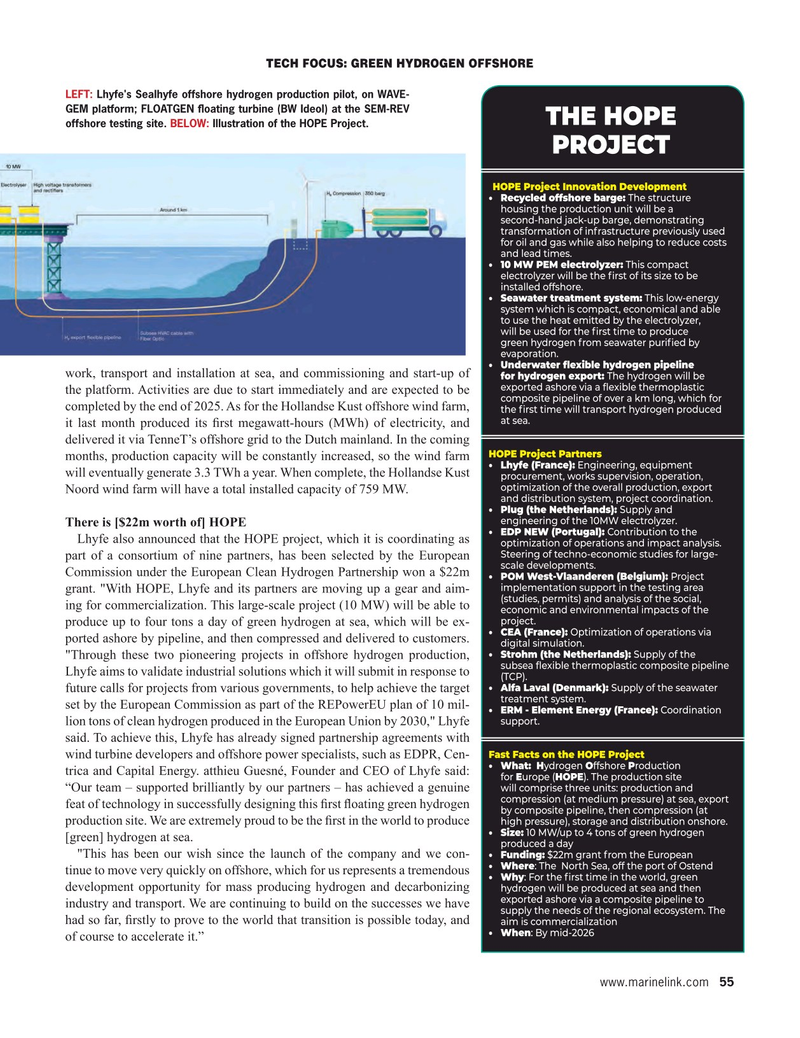

LEFT: Lhyfe's Sealhyfe offshore hydrogen production pilot, on WAVE-

GEM platform; FLOATGEN ? oating turbine (BW Ideol) at the SEM-REV

THE HOPE offshore testing site. BELOW: Illustration of the HOPE Project.

PROJECT

HOPE Project Innovation Development • Recycled offshore barge: The structure housing the production unit will be a second-hand jack-up barge, demonstrating transformation of infrastructure previously used for oil and gas while also helping to reduce costs and lead times.

• 10 MW PEM electrolyzer: This compact electrolyzer will be the ? rst of its size to be installed offshore.

• Seawater treatment system: This low-energy system which is compact, economical and able to use the heat emitted by the electrolyzer, will be used for the ? rst time to produce green hydrogen from seawater puri? ed by evaporation.

• Underwater ? exible hydrogen pipeline work, transport and installation at sea, and commissioning and start-up of for hydrogen export: The hydrogen will be exported ashore via a ? exible thermoplastic the platform. Activities are due to start immediately and are expected to be composite pipeline of over a km long, which for completed by the end of 2025. As for the Hollandse Kust offshore wind farm, the ? rst time will transport hydrogen produced at sea.

it last month produced its ? rst megawatt-hours (MWh) of electricity, and delivered it via TenneT’s offshore grid to the Dutch mainland. In the coming

HOPE Project Partners months, production capacity will be constantly increased, so the wind farm • Lhyfe (France): Engineering, equipment will eventually generate 3.3 TWh a year. When complete, the Hollandse Kust procurement, works supervision, operation, optimization of the overall production, export

Noord wind farm will have a total installed capacity of 759 MW.

and distribution system, project coordination.

• Plug (the Netherlands): Supply and engineering of the 10MW electrolyzer.

There is [$22m worth of] HOPE • EDP NEW (Portugal): Contribution to the

Lhyfe also announced that the HOPE project, which it is coordinating as optimization of operations and impact analysis.

Steering of techno-economic studies for large- part of a consortium of nine partners, has been selected by the European scale developments.

Commission under the European Clean Hydrogen Partnership won a $22m • POM West-Vlaanderen (Belgium): Project implementation support in the testing area grant. "With HOPE, Lhyfe and its partners are moving up a gear and aim- (studies, permits) and analysis of the social, ing for commercialization. This large-scale project (10 MW) will be able to economic and environmental impacts of the project.

produce up to four tons a day of green hydrogen at sea, which will be ex- • CEA (France): Optimization of operations via ported ashore by pipeline, and then compressed and delivered to customers. digital simulation.

• Strohm (the Netherlands): Supply of the "Through these two pioneering projects in offshore hydrogen production, subsea ? exible thermoplastic composite pipeline

Lhyfe aims to validate industrial solutions which it will submit in response to (TCP).

• Alfa Laval (Denmark): Supply of the seawater future calls for projects from various governments, to help achieve the target treatment system.

set by the European Commission as part of the REPowerEU plan of 10 mil- • ERM - Element Energy (France): Coordination support.

lion tons of clean hydrogen produced in the European Union by 2030," Lhyfe said. To achieve this, Lhyfe has already signed partnership agreements with

Fast Facts on the HOPE Project wind turbine developers and offshore power specialists, such as EDPR, Cen- • What: Hydrogen Offshore Production trica and Capital Energy. atthieu Guesné, Founder and CEO of Lhyfe said: for Europe (HOPE). The production site will comprise three units: production and “Our team – supported brilliantly by our partners – has achieved a genuine compression (at medium pressure) at sea, export feat of technology in successfully designing this ? rst ? oating green hydrogen by composite pipeline, then compression (at production site. We are extremely proud to be the ? rst in the world to produce high pressure), storage and distribution onshore.

• Size: 10 MW/up to 4 tons of green hydrogen [green] hydrogen at sea. produced a day "This has been our wish since the launch of the company and we con- • Funding: $22m grant from the European • Where: The North Sea, off the port of Ostend tinue to move very quickly on offshore, which for us represents a tremendous • Why: For the ? rst time in the world, green development opportunity for mass producing hydrogen and decarbonizing hydrogen will be produced at sea and then exported ashore via a composite pipeline to industry and transport. We are continuing to build on the successes we have supply the needs of the regional ecosystem. The had so far, ? rstly to prove to the world that transition is possible today, and aim is commercialization • When: By mid-2026 of course to accelerate it.” www.marinelink.com 55

MR #8 (50-60).indd 55 8/4/2023 8:51:57 AM

54

54

56

56