Page 19: of Maritime Reporter Magazine (January 2024)

Read this page in Pdf, Flash or Html5 edition of January 2024 Maritime Reporter Magazine

COATINGS

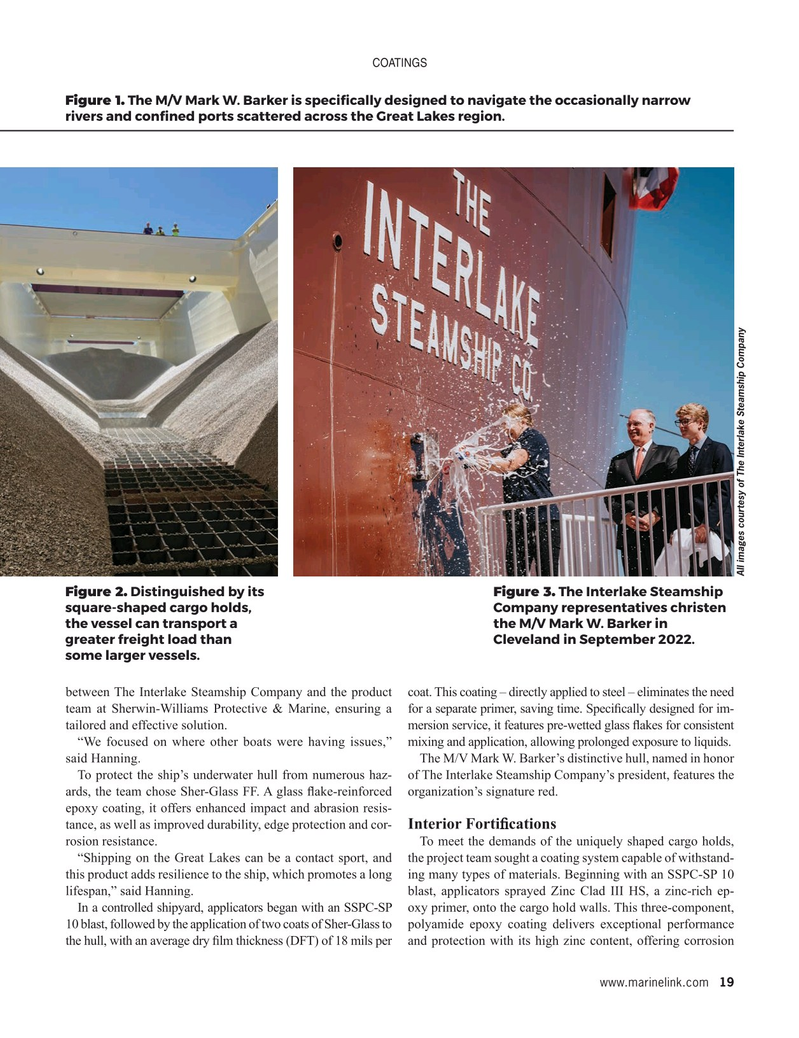

Figure 1. The M/V Mark W. Barker is speci? cally designed to navigate the occasionally narrow rivers and con? ned ports scattered across the Great Lakes region.

All images courtesy of The Interlake Steamship Company

Figure 2. Distinguished by its Figure 3. The Interlake Steamship square-shaped cargo holds, Company representatives christen the vessel can transport a the M/V Mark W. Barker in greater freight load than Cleveland in September 2022.

some larger vessels.

between The Interlake Steamship Company and the product coat. This coating – directly applied to steel – eliminates the need team at Sherwin-Williams Protective & Marine, ensuring a for a separate primer, saving time. Speci? cally designed for im- tailored and effective solution. mersion service, it features pre-wetted glass ? akes for consistent “We focused on where other boats were having issues,” mixing and application, allowing prolonged exposure to liquids.

said Hanning. The M/V Mark W. Barker’s distinctive hull, named in honor

To protect the ship’s underwater hull from numerous haz- of The Interlake Steamship Company’s president, features the ards, the team chose Sher-Glass FF. A glass ? ake-reinforced organization’s signature red.

epoxy coating, it offers enhanced impact and abrasion resis- tance, as well as improved durability, edge protection and cor- Interior Forti? cations rosion resistance. To meet the demands of the uniquely shaped cargo holds, “Shipping on the Great Lakes can be a contact sport, and the project team sought a coating system capable of withstand- this product adds resilience to the ship, which promotes a long ing many types of materials. Beginning with an SSPC-SP 10 lifespan,” said Hanning. blast, applicators sprayed Zinc Clad III HS, a zinc-rich ep-

In a controlled shipyard, applicators began with an SSPC-SP oxy primer, onto the cargo hold walls. This three-component, 10 blast, followed by the application of two coats of Sher-Glass to polyamide epoxy coating delivers exceptional performance the hull, with an average dry ? lm thickness (DFT) of 18 mils per and protection with its high zinc content, offering corrosion www.marinelink.com 19

MR #1 (18-33).indd 19 1/8/2024 11:09:49 AM

18

18

20

20