Page 21: of Maritime Reporter Magazine (January 2024)

Read this page in Pdf, Flash or Html5 edition of January 2024 Maritime Reporter Magazine

COATINGS

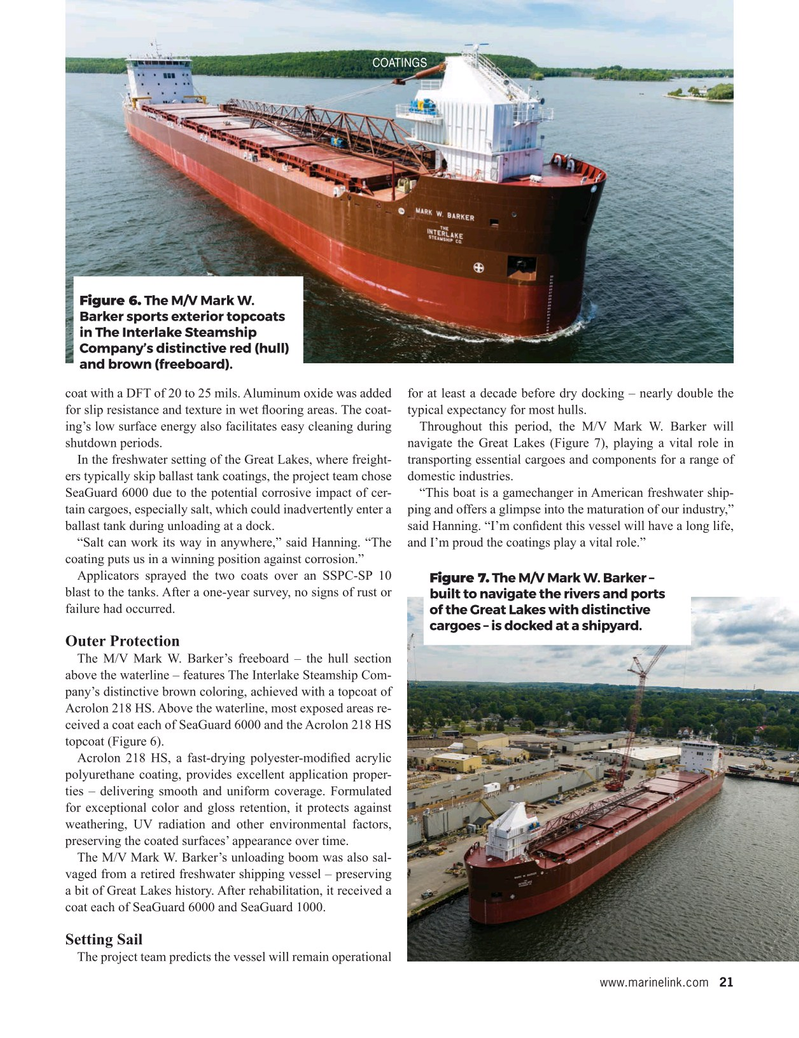

Figure 6. The M/V Mark W.

Barker sports exterior topcoats in The Interlake Steamship

Company’s distinctive red (hull) and brown (freeboard).

coat with a DFT of 20 to 25 mils. Aluminum oxide was added for at least a decade before dry docking – nearly double the for slip resistance and texture in wet ? ooring areas. The coat- typical expectancy for most hulls. ing’s low surface energy also facilitates easy cleaning during Throughout this period, the M/V Mark W. Barker will shutdown periods. navigate the Great Lakes (Figure 7), playing a vital role in

In the freshwater setting of the Great Lakes, where freight- transporting essential cargoes and components for a range of ers typically skip ballast tank coatings, the project team chose domestic industries.

SeaGuard 6000 due to the potential corrosive impact of cer- “This boat is a gamechanger in American freshwater ship- tain cargoes, especially salt, which could inadvertently enter a ping and offers a glimpse into the maturation of our industry,” ballast tank during unloading at a dock. said Hanning. “I’m con? dent this vessel will have a long life, “Salt can work its way in anywhere,” said Hanning. “The and I’m proud the coatings play a vital role.” coating puts us in a winning position against corrosion.”

Applicators sprayed the two coats over an SSPC-SP 10

Figure 7. The M/V Mark W. Barker – blast to the tanks. After a one-year survey, no signs of rust or built to navigate the rivers and ports failure had occurred.

of the Great Lakes with distinctive cargoes – is docked at a shipyard.

Outer Protection

The M/V Mark W. Barker’s freeboard – the hull section above the waterline – features The Interlake Steamship Com- pany’s distinctive brown coloring, achieved with a topcoat of

Acrolon 218 HS. Above the waterline, most exposed areas re- ceived a coat each of SeaGuard 6000 and the Acrolon 218 HS topcoat (Figure 6).

Acrolon 218 HS, a fast-drying polyester-modi? ed acrylic polyurethane coating, provides excellent application proper- ties – delivering smooth and uniform coverage. Formulated for exceptional color and gloss retention, it protects against weathering, UV radiation and other environmental factors, preserving the coated surfaces’ appearance over time.

The M/V Mark W. Barker’s unloading boom was also sal- vaged from a retired freshwater shipping vessel – preserving a bit of Great Lakes history. After rehabilitation, it received a coat each of SeaGuard 6000 and SeaGuard 1000.

Setting Sail

The project team predicts the vessel will remain operational www.marinelink.com 21

MR #1 (18-33).indd 21 1/9/2024 12:36:34 PM

20

20

22

22