Page 32: of Maritime Reporter Magazine (December 2024)

Read this page in Pdf, Flash or Html5 edition of December 2024 Maritime Reporter Magazine

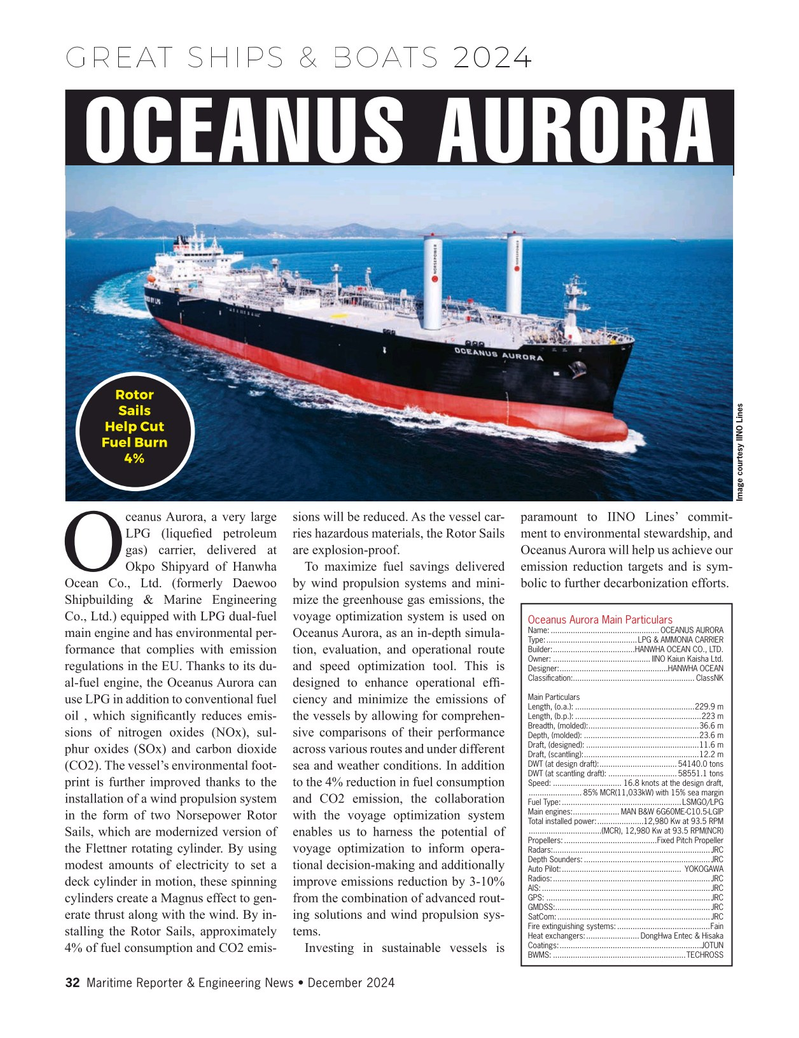

OCEANUS AURORA

Rotor

Sails

Help Cut

Fuel Burn 4%

Image courtesy IINO Lines ceanus Aurora, a very large sions will be reduced. As the vessel car- paramount to IINO Lines’ commit-

LPG (lique? ed petroleum ries hazardous materials, the Rotor Sails ment to environmental stewardship, and gas) carrier, delivered at are explosion-proof. Oceanus Aurora will help us achieve our

OOkpo Shipyard of Hanwha To maximize fuel savings delivered emission reduction targets and is sym-

Ocean Co., Ltd. (formerly Daewoo by wind propulsion systems and mini- bolic to further decarbonization efforts.

Shipbuilding & Marine Engineering mize the greenhouse gas emissions, the

Co., Ltd.) equipped with LPG dual-fuel voyage optimization system is used on

Oceanus Aurora Main Particulars

Name: .................................................OCEANUS AURORA main engine and has environmental per- Oceanus Aurora, as an in-depth simula-

Type: .........................................LPG & AMMONIA CARRIER

Builder: .....................................HANWHA OCEAN CO., LTD.

formance that complies with emission tion, evaluation, and operational route

Owner: ............................................IINO Kaiun Kaisha Ltd.

regulations in the EU. Thanks to its du- and speed optimization tool. This is

Designer: .................................................HANWHA OCEAN

Classi? cation: .......................................................ClassNK al-fuel engine, the Oceanus Aurora can designed to enhance operational ef? -

Main Particulars use LPG in addition to conventional fuel ciency and minimize the emissions of

Length, (o.a.): ......................................................229.9 m

Length, (b.p.): .........................................................223 m oil , which signi? cantly reduces emis- the vessels by allowing for comprehen-

Breadth, (molded): ..................................................36.6 m sions of nitrogen oxides (NOx), sul- sive comparisons of their performance

Depth, (molded): ....................................................23.6 m

Draft, (designed): ...................................................11.6 m phur oxides (SOx) and carbon dioxide across various routes and under different

Draft, (scantling): ....................................................12.2 m

DWT (at design draft): ...................................54140.0 tons (CO2). The vessel’s environmental foot- sea and weather conditions. In addition

DWT (at scantling draft): ...............................58551.1 tons

Speed: ...............................16.8 knots at the design draft, print is further improved thanks to the to the 4% reduction in fuel consumption ........................85% MCR(11,033kW) with 15% sea margin installation of a wind propulsion system and CO2 emission, the collaboration

Fuel Type: ......................................................LSMGO/LPG

Main engines: .....................MAN B&W 6G60ME-C10.5-LGIP in the form of two Norsepower Rotor with the voyage optimization system

Total installed power: .....................12,980 Kw at 93.5 RPM .................................(MCR), 12,980 Kw at 93.5 RPM(NCR)

Sails, which are modernized version of enables us to harness the potential of

Propellers: ..........................................Fixed Pitch Propeller the Flettner rotating cylinder. By using voyage optimization to inform opera-

Radars:.......................................................................JRC

Depth Sounders: .........................................................JRC modest amounts of electricity to set a tional decision-making and additionally

Auto Pilot: ...................................................... YOKOGAWA

Radios: .......................................................................JRC deck cylinder in motion, these spinning improve emissions reduction by 3-10%

AIS: ............................................................................JRC

GPS: ..........................................................................JRC cylinders create a Magnus effect to gen- from the combination of advanced rout-

GMDSS: ......................................................................JRC erate thrust along with the wind. By in- ing solutions and wind propulsion sys-

SatCom: .....................................................................JRC

Fire extinguishing systems: ..........................................Fain stalling the Rotor Sails, approximately tems.

Heat exchangers: ........................DongHwa Entec & Hisaka

Coatings: ................................................................JOTUN 4% of fuel consumption and CO2 emis- Investing in sustainable vessels is

BWMS: ............................................................TECHROSS 32 Maritime Reporter & Engineering News • December 2024

MR #12 (18-33).indd 32 12/5/2024 9:12:47 AM

31

31

33

33