Page 20: of Maritime Reporter Magazine (August 2025)

Read this page in Pdf, Flash or Html5 edition of August 2025 Maritime Reporter Magazine

Safety Solutions – Sponsored

Wooster Products’ Stair Treads Support

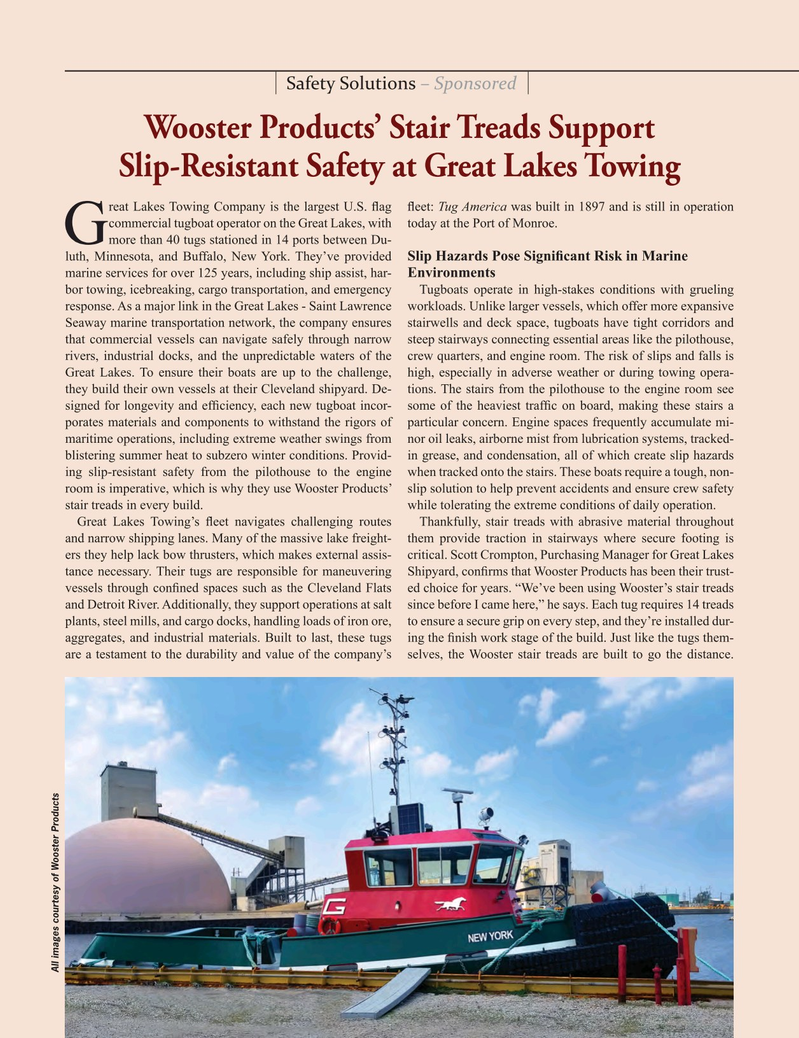

Slip-Resistant Safety at Great Lakes Towing reat Lakes Towing Company is the largest U.S. ? ag ? eet: Tug America was built in 1897 and is still in operation commercial tugboat operator on the Great Lakes, with today at the Port of Monroe.

Gmore than 40 tugs stationed in 14 ports between Du- luth, Minnesota, and Buffalo, New York. They’ve provided

Slip Hazards Pose Signi? cant Risk in Marine marine services for over 125 years, including ship assist, har-

Environments bor towing, icebreaking, cargo transportation, and emergency Tugboats operate in high-stakes conditions with grueling response. As a major link in the Great Lakes - Saint Lawrence workloads. Unlike larger vessels, which offer more expansive

Seaway marine transportation network, the company ensures stairwells and deck space, tugboats have tight corridors and that commercial vessels can navigate safely through narrow steep stairways connecting essential areas like the pilothouse, rivers, industrial docks, and the unpredictable waters of the crew quarters, and engine room. The risk of slips and falls is

Great Lakes. To ensure their boats are up to the challenge, high, especially in adverse weather or during towing opera- they build their own vessels at their Cleveland shipyard. De- tions. The stairs from the pilothouse to the engine room see signed for longevity and ef? ciency, each new tugboat incor- some of the heaviest traf? c on board, making these stairs a porates materials and components to withstand the rigors of particular concern. Engine spaces frequently accumulate mi- maritime operations, including extreme weather swings from nor oil leaks, airborne mist from lubrication systems, tracked- blistering summer heat to subzero winter conditions. Provid- in grease, and condensation, all of which create slip hazards ing slip-resistant safety from the pilothouse to the engine when tracked onto the stairs. These boats require a tough, non- room is imperative, which is why they use Wooster Products’ slip solution to help prevent accidents and ensure crew safety stair treads in every build. while tolerating the extreme conditions of daily operation.

Great Lakes Towing’s ? eet navigates challenging routes Thankfully, stair treads with abrasive material throughout and narrow shipping lanes. Many of the massive lake freight- them provide traction in stairways where secure footing is ers they help lack bow thrusters, which makes external assis- critical. Scott Crompton, Purchasing Manager for Great Lakes tance necessary. Their tugs are responsible for maneuvering Shipyard, con? rms that Wooster Products has been their trust- vessels through con? ned spaces such as the Cleveland Flats ed choice for years. “We’ve been using Wooster’s stair treads and Detroit River. Additionally, they support operations at salt since before I came here,” he says. Each tug requires 14 treads plants, steel mills, and cargo docks, handling loads of iron ore, to ensure a secure grip on every step, and they’re installed dur- aggregates, and industrial materials. Built to last, these tugs ing the ? nish work stage of the build. Just like the tugs them- are a testament to the durability and value of the company’s selves, the Wooster stair treads are built to go the distance.

All images courtesy of Wooster Products

MR #8 (18-33).indd 20 MR #8 (18-33).indd 20 8/1/2025 5:17:53 PM8/1/2025 5:17:53 PM

19

19

21

21