Page 46: of Maritime Reporter Magazine (August 2025)

Read this page in Pdf, Flash or Html5 edition of August 2025 Maritime Reporter Magazine

SHIPBUILDING | U.S. MID-SIZED YARDS

AUSTAL USA AUSTAL USA

EXPANDS CAPACITY, EXPANDS CAPACITY,

CAPABILITY CAPABILITY

All images courtesy Austal USA s maritime holistically, shipbuilding speci? - set up to deliver complex ships ef? ciently,” Ryder said.

cally, comes to the forefront of U.S. politics, The Mobile yard includes more than 1 million square feet of

Austal USA is positioned to capitalize. From its indoor production space, a 740,000-sq.-ft. module manufactur-

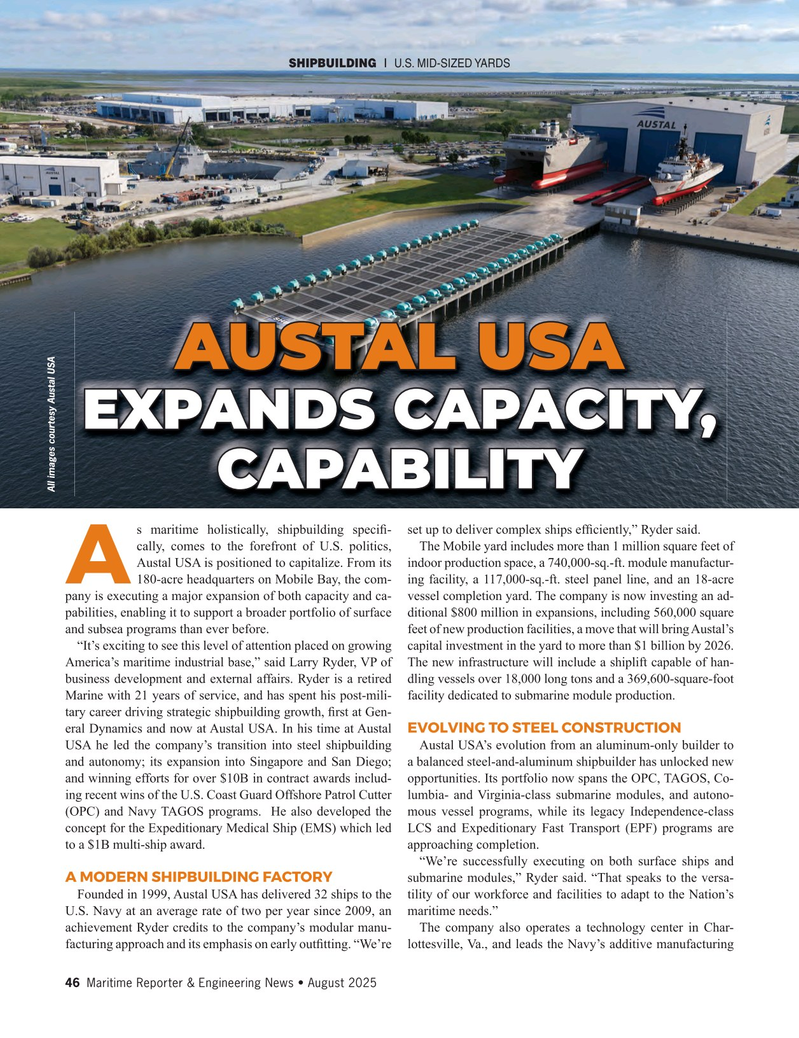

A 180-acre headquarters on Mobile Bay, the com- ing facility, a 117,000-sq.-ft. steel panel line, and an 18-acre pany is executing a major expansion of both capacity and ca- vessel completion yard. The company is now investing an ad- pabilities, enabling it to support a broader portfolio of surface ditional $800 million in expansions, including 560,000 square and subsea programs than ever before. feet of new production facilities, a move that will bring Austal’s “It’s exciting to see this level of attention placed on growing capital investment in the yard to more than $1 billion by 2026.

America’s maritime industrial base,” said Larry Ryder, VP of The new infrastructure will include a shiplift capable of han- business development and external affairs. Ryder is a retired dling vessels over 18,000 long tons and a 369,600-square-foot

Marine with 21 years of service, and has spent his post-mili- facility dedicated to submarine module production.

tary career driving strategic shipbuilding growth, ? rst at Gen-

EVOLVING TO STEEL CONSTRUCTION eral Dynamics and now at Austal USA. In his time at Austal

USA he led the company’s transition into steel shipbuilding Austal USA’s evolution from an aluminum-only builder to and autonomy; its expansion into Singapore and San Diego; a balanced steel-and-aluminum shipbuilder has unlocked new and winning efforts for over $10B in contract awards includ- opportunities. Its portfolio now spans the OPC, TAGOS, Co- ing recent wins of the U.S. Coast Guard Offshore Patrol Cutter lumbia- and Virginia-class submarine modules, and autono- (OPC) and Navy TAGOS programs. He also developed the mous vessel programs, while its legacy Independence-class concept for the Expeditionary Medical Ship (EMS) which led LCS and Expeditionary Fast Transport (EPF) programs are to a $1B multi-ship award. approaching completion.

“We’re successfully executing on both surface ships and

A MODERN SHIPBUILDING FACTORY submarine modules,” Ryder said. “That speaks to the versa-

Founded in 1999, Austal USA has delivered 32 ships to the tility of our workforce and facilities to adapt to the Nation’s

U.S. Navy at an average rate of two per year since 2009, an maritime needs.” achievement Ryder credits to the company’s modular manu- The company also operates a technology center in Char- facturing approach and its emphasis on early out? tting. “We’re lottesville, Va., and leads the Navy’s additive manufacturing 46 Maritime Reporter & Engineering News • August 2025

MR #8 (34-49).indd 46 MR #8 (34-49).indd 46 8/1/2025 5:10:16 PM8/1/2025 5:10:16 PM

45

45

47

47