Page 51: of Maritime Reporter Magazine (November 2025)

Read this page in Pdf, Flash or Html5 edition of November 2025 Maritime Reporter Magazine

ENERGY ONBOARD | WASTE HEAT

Modular ORC-based waste heat recovery packages have ules is lower than at full load. To address this, shipowners are been introduced designed for retro? t in constrained engine increasingly adopting a portfolio approach: combining high- rooms with skid or split-skid options. temperature recovery modules on the exhaust, steam, or ther-

Multi-source heat harvesting is now possible, combining mal oil side with lower-temperature units, like the ePM200 exhaust economizers, high- and low-temperature jacket water, XR, on hot water loops. This ensures meaningful energy re- steam systems via economizers, and thermal oil systems into a covery even at partial loads.” single power module. Modern ORC controls further optimize performance dy-

Hybrid integration blocks with shaft generators or batteries namically, keeping modules online and ef? cient across vary- allow operators to prioritize recovered energy where it offsets ing operating conditions. As a result, owners can maintain the most expensive kWh on board. compliance with ef? ciency and emissions regulations, capture

Together with higher-temperature modules, the Orcan En- OPEX and CO savings, and reduce reliance on slow steaming 2 ergy ePM200 XR enables the recovery of energy across a without sacri? cing operational ? exibility, says van Sluijs.

wide temperature range and operational pro? le, capturing Waste heat recovery partners well with new fuels such as value both at high-load cruising and lower-load conditions. methanol. System manufacturer Climeon foresees the already

The ePM200 XR is a new lower-temperature waste heat re- favorable payback period for its ORC waste heat recovery covery unit optimized for moderate-temperature sources, such system as potentially being cut in half by 2030.

as jacket water or auxiliary cooling loops (80–120°C). It de- “Vessels operating on alternative marine fuels typically livers up to ~200 kW net electrical output, ideal for vessels offer a more favorable waste heat pro? le for ORC systems with limited exhaust heat or those operating at part load or compared to those running on HFO,” says Fredrik Thoren, ex- slow steaming. ecutive vice president, head of marine sales at Climeon. “For

Yes, slow steaming does impact shipowners’ decisions on example, methanol-fueled vessels often require less auxiliary adopting waste heat recovery, says van Sluijs. “At reduced heating, such as tank heating, which means more waste heat is engine loads, there is less exhaust and system heat available, available for recovery. In many cases, this allows the Climeon so the net output from traditional waste heat recovery mod- HeatPower 300 to generate more electricity.

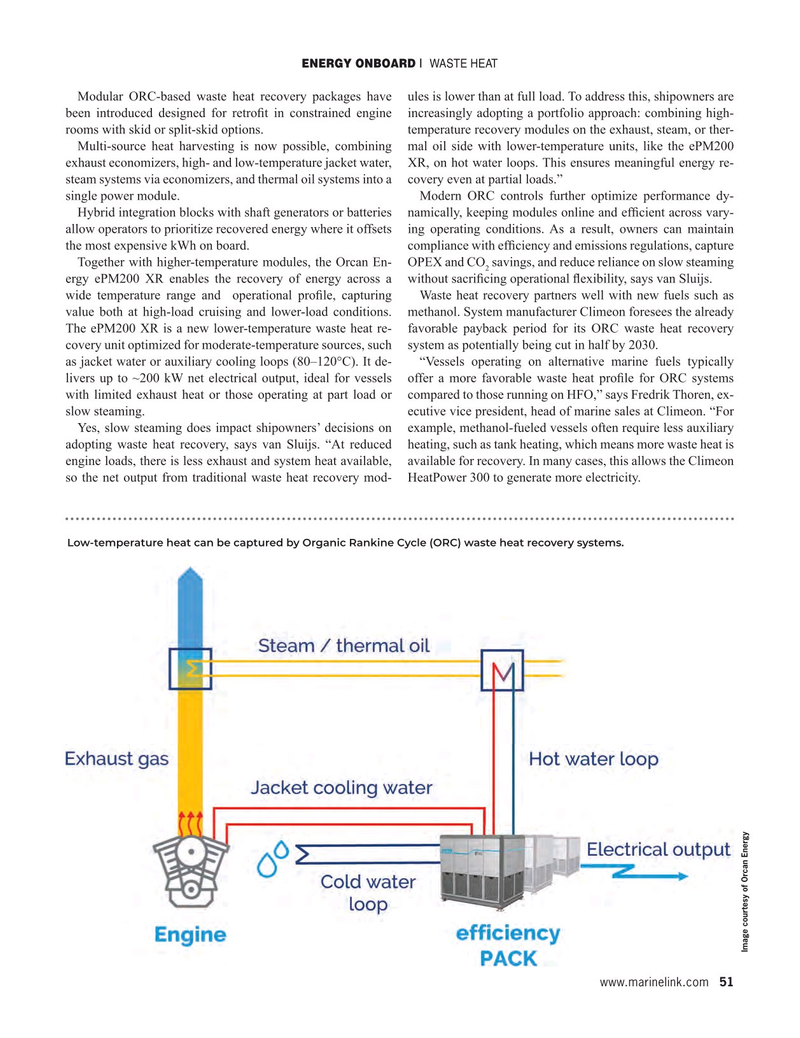

Low-temperature heat can be captured by Organic Rankine Cycle (ORC) waste heat recovery systems.

Image courtesy of Orcan Energy www.marinelink.com 51

MR #11 (50-65).indd 51 MR #11 (50-65).indd 51 11/2/2025 8:25:35 PM11/2/2025 8:25:35 PM

50

50

52

52