Page 47: of Offshore Engineer Magazine (Mar/Apr 2013)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2013 Offshore Engineer Magazine

l Background noise reduction.

Leak detection systems l Operational reliability.

Considering the Arctic’s environmental sensitivity,

Subsea continuous leak monitoring may be

Internal-based External-based preferred rather than periodic leak testing. Installation of continuous leak monitoring systems may help operators in permit application

Pressure/Flow Capacitance and regulatory review. Rapid and reliable leak detection and

Periodic leak location identifcation are important

Acoustic Vapor sensing aspects for safe arctic hydrocarbon development.

Intelligent

Balancing Optical camera

Existing technologies

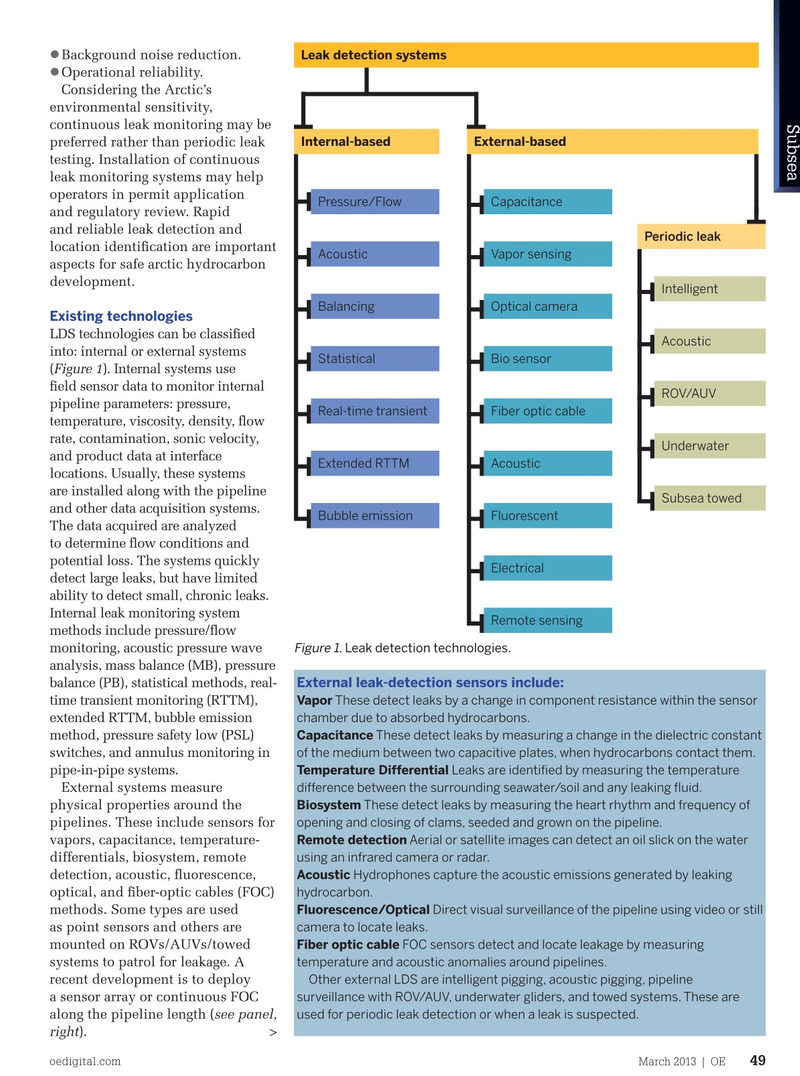

LDS technologies can be classifed

Acoustic into: internal or external systems

Statistical Bio sensor (Figure 1). Internal systems use feld sensor data to monitor internal

ROV/AUV pipeline parameters: pressure,

Real-time transient Fiber optic cable temperature, viscosity, density, fow rate, contamination, sonic velocity,

Underwater and product data at interface

Extended RTTM Acoustic locations. Usually, these systems are installed along with the pipeline

Subsea towed and other data acquisition systems.

Bubble emission Fluorescent

The data acquired are analyzed to determine fow conditions and potential loss. The systems quickly

Electrical detect large leaks, but have limited ability to detect small, chronic leaks.

Internal leak monitoring system

Remote sensing methods include pressure/fow monitoring, acoustic pressure wave

Figure 1.

Leak detection technologies.

analysis, mass balance (MB), pressure balance (PB), statistical methods, real- External leak-detection sensors include: time transient monitoring (RTTM),

Vapor These detect leaks by a change in component resistance within the sensor extended RTTM, bubble emission chamber due to absorbed hydrocarbons.

method, pressure safety low (PSL)

Capacitance These detect leaks by measuring a change in the dielectric constant switches, and annulus monitoring in of the medium between two capacitive plates, when hydrocarbons contact them.

pipe-in-pipe systems.

Temperature Differential Leaks are identifed by measuring the temperature External systems measure difference between the surrounding seawater/soil and any leaking fuid.

physical properties around the

Biosystem These detect leaks by measuring the heart rhythm and frequency of pipelines. These include sensors for opening and closing of clams, seeded and grown on the pipeline.

vapors, capacitance, temperature-

Remote detection Aerial or satellite images can detect an oil slick on the water differentials, biosystem, remote using an infrared camera or radar. detection, acoustic, fuorescence,

Acoustic Hydrophones capture the acoustic emissions generated by leaking optical, and fber-optic cables (FOC) hydrocarbon.

methods. Some types are used

Fluorescence/Optical Direct visual surveillance of the pipeline using video or still as point sensors and others are camera to locate leaks.

mounted on ROVs/AUVs/towed

Fiber optic cable FOC sensors detect and locate leakage by measuring systems to patrol for leakage. A temperature and acoustic anomalies around pipelines.

recent development is to deploy Other external LDS are intelligent pigging, acoustic pigging, pipeline a sensor array or continuous FOC surveillance with ROV/AUV, underwater gliders, and towed systems. These are along the pipeline length (see panel, used for periodic leak detection or when a leak is suspected.

right). > oedigital.com March 2013 | OE 49 oe_subseaINTECSEA_rev3.indd 49 27/02/2013 11:55

46

46

48

48